The Strategic Importance of PCB Prototyping in Global Electronics Manufacturing

Why PCB Prototyping is Critical for International Electronics Trade

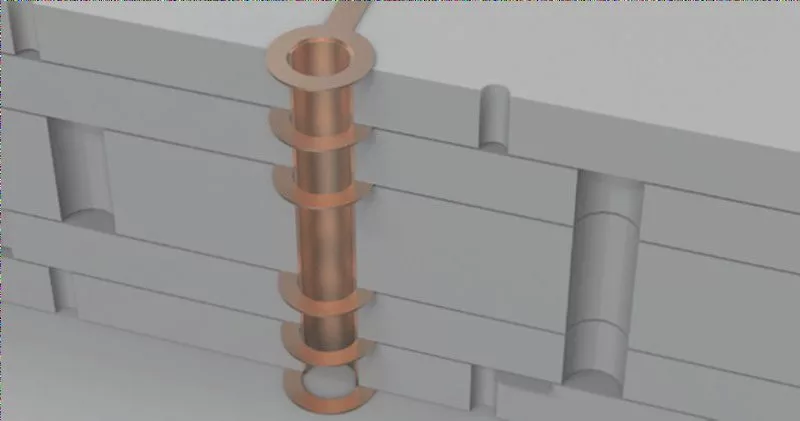

For businesses engaged in PCB manufacturing in China or sourcing high-quality circuit boards internationally, prototyping serves as the crucial bridge between design and mass production. This essential step not only validates product quality but significantly reduces defects in full-scale manufacturing – a key concern for global electronics exporters.

Key Benefits of Professional PCB Prototyping Services

- Manufacturer capability assessment – Evaluate new suppliers’ technical competencies

- Defect prevention – Identify and resolve issues before mass production

- Cost optimization – Calculate accurate material requirements and pricing

- Performance validation – Test functionality under real-world conditions

How PCB Prototyping Enhances International Trade Operations

1. Evaluating Manufacturing Partners for Global Supply Chains

When working with PCB manufacturers in China or other manufacturing hubs, prototyping provides tangible proof of a supplier’s capabilities. This is particularly valuable for:

- First-time collaborations with overseas partners

- Verification of technical specifications compliance

- Assessment of quality control processes

“Prototyping is the litmus test for identifying reliable PCB manufacturing partners in the global marketplace.” – Industry Expert

2. Minimizing Risks in High-Volume Production

For electronics exporters dealing with large orders, prototyping helps answer critical questions:

- How to reduce PCB defect rates in mass production?

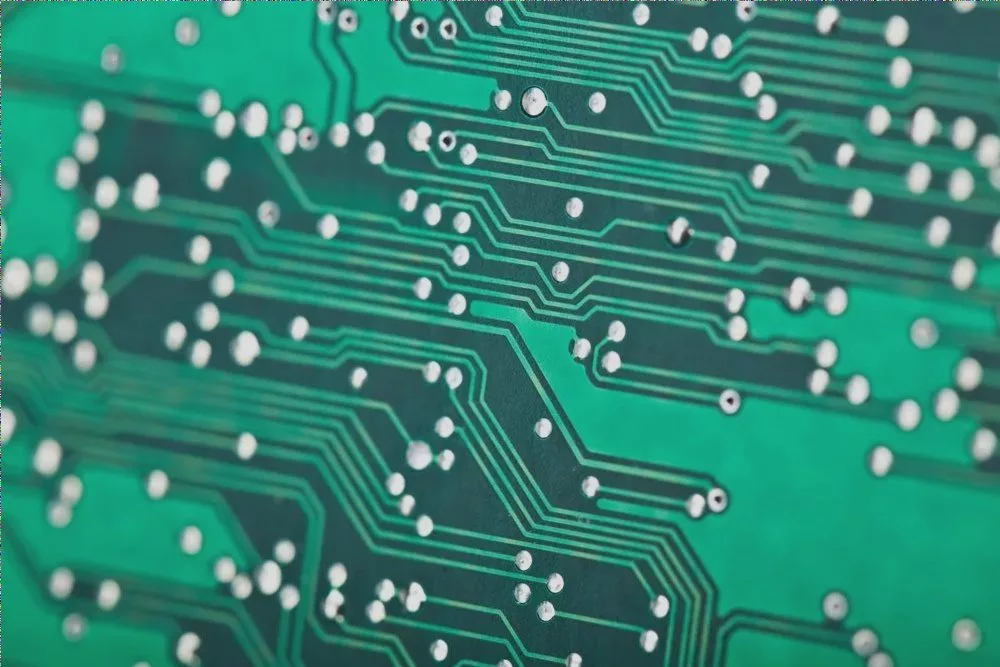

- What are the best prototyping methods for complex multilayer boards?

- How to ensure consistency across international production runs?

3. Cost-Effective Product Development for Export Markets

Prototyping enables businesses to:

- Accurately forecast material requirements and costs

- Optimize designs for manufacturability

- Test alternative components for global compliance

Best Practices for Successful PCB Prototyping in International Trade

Essential Pre-Prototyping Considerations

Before initiating your PCB prototype manufacturing process, ensure:

- Complete design documentation with international standards

- Clear communication of all technical parameters

- Agreement on testing protocols and quality benchmarks

Selecting the Right Prototyping Partner

Key factors when choosing a PCB prototype service provider:

- Experience with your specific product category

- Certifications for target export markets (CE, UL, RoHS)

- Multilingual technical support capabilities

- Proven track record with international clients

Conclusion: Prototyping as a Strategic Advantage

In today’s competitive global electronics market, comprehensive PCB prototyping has evolved from an optional step to a critical business strategy. By investing in thorough prototyping processes, international traders and manufacturers can:

- Reduce time-to-market for new products

- Minimize costly production errors

- Build stronger relationships with overseas partners

- Ensure consistent quality across global supply chains

For businesses looking to source PCBs from China or other manufacturing centers, a robust prototyping phase establishes the foundation for successful long-term partnerships and profitable international trade operations.