You are in a lab. A prototype fails at the last step. The screen stays black. The camera does not respond. In many cases, the root cause is simple. The flex cable was flipped. Or the latch was not fully closed. I have seen this happen on new builds and “easy” rework jobs.

This guide is built for that moment. I will explain the FPC cable’s meaning in plain terms. I will also cover what makes an FPC different from an FFC. You will learn how to pick an FPC cable connector. You will see common failure modes and safe FPC cable repair options. I will also share a practical example for fpc cable Raspberry Pi use, since that is a common dev setup. The goal is simple. You should leave with fewer surprises and faster debug cycles.

What an FPC cable is, in plain terms

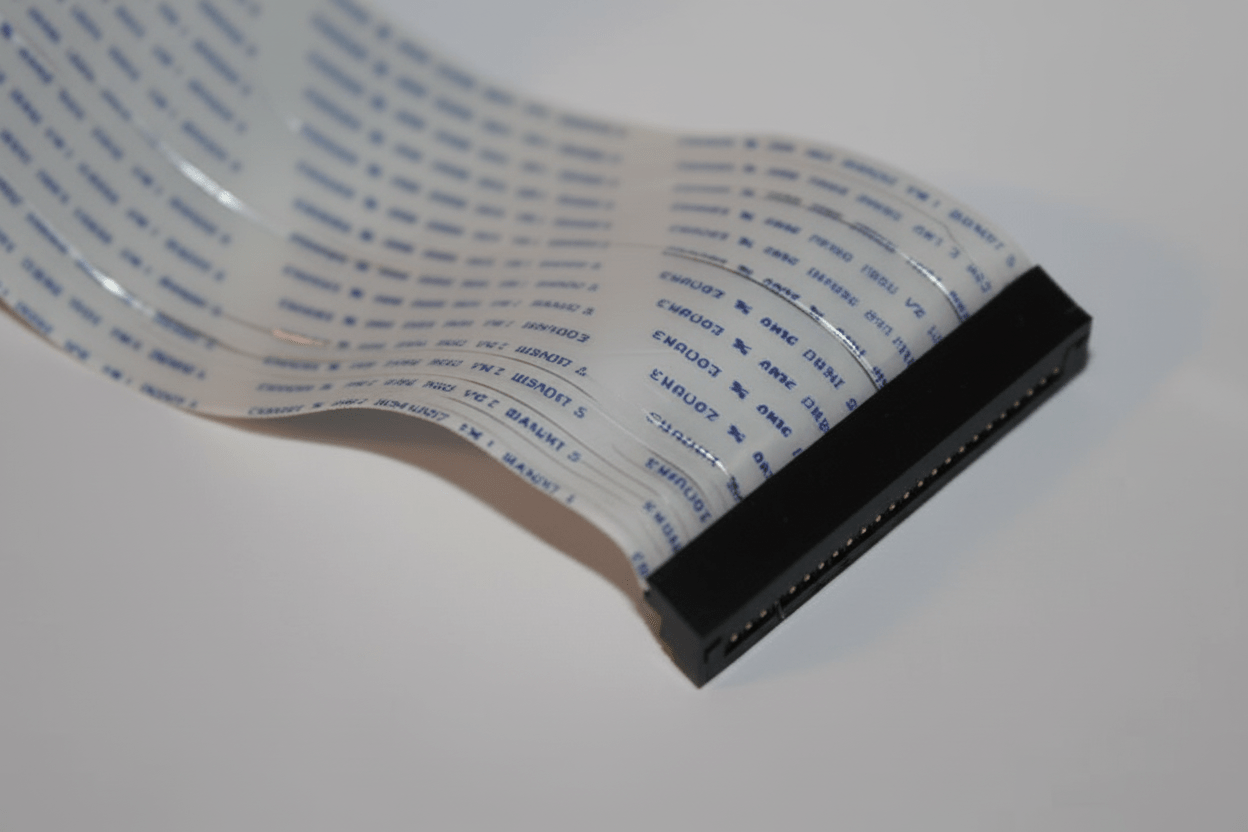

Let’s clear up the name. The FPC cable’s full form is Flexible Printed Circuit. Many teams call it a “flex cable.” It is not a bundle of loose wires. Copper traces are etched onto a thin film. That film is usually polyimide. The circuit is then covered by a protective layer.

An FPC can do many of the same jobs as a rigid PCB. It can carry power, data, and control lines. The difference is the shape and how it moves. A rigid PCB stays flat. An FPC can bend and fold. That matters in tight spaces.

I remember a small wearable project with a curved battery cavity. A rigid interconnect failed the fit check. The product team wanted a thinner stack. We moved to an FPC with a controlled bend area. The final assembly height dropped by about 1.2 mm. That change made the enclosure work.

Most engineers do not realize one thing at first. The cable is part of the circuit design. The “pins” at the end are not separate parts. They are exposed copper pads. Their order is the “pinout.” A wrong pinout can kill a bring-up.

- FPC uses printed copper traces on a flexible base.

- Pads act as the end contacts. They mate with a connector.

- Pinout is the pad order. It must match the mating board.

FPC vs FFC: when each one makes sense

People mix these terms. That causes bad sourcing choices. An FFC is a flat cable, too, but it is built from parallel metal conductors. Those conductors are laminated in a flat strip. An FFC is often used for a 1:1 connection. It is common in printers and consumer devices.

An FPC is different. It can include impedance control, ground fills, and special shapes. It can also include stiffeners, shielding, and even components in some designs. That freedom is why many camera modules use an FPC.

Think about repeated bending. FFCs are used in some high-flex cases. Life depends on the cable design and bend radius. FPCs can also be designed for dynamic flex. Yet you must design the bend area carefully. IPC-2223 is the key design standard for flexible printed boards. It covers bend rules and layout guidance.

There is also the “Type A” and “Type D” idea for FFC contact orientation. Type A has contacts on the same side on both ends. Type D flips the contact side on one end. That detail decides cable routing.

Table: FPC vs FFC at a practical level

| Construction | Etched copper traces on polyimide film | Flat conductors laminated in a ribbon |

| Best use | Custom shapes, dense routing, special stackups | Simple 1:1 links, fast assembly swaps |

| Design standard | IPC-2223 guidance is commonly used | No single design standard covers all builds |

| Common contact style | Exposed pads with stiffener support | Exposed conductors, Type A or Type D layout |

| Typical buyer question | “Can you meet impedance and bend life?” | “Is the pitch and contact side correct?” |

Inside an FPC: materials, layers, and stiffeners

A reliable FPC starts with the stack. Polyimide is the most common base film. Copper foil is laminated on it. Adhesive or adhesive-less builds are both used. Adhesive-less stackups often help with tighter bending. The right choice depends on cost and flex life needs.

Coverlay is also important. It protects copper traces in the bend area. It is not the same as a solder mask on rigid boards. The openings in the coverlay define exposed pads. Those pads are where the connector grips.

Stiffeners are the hidden hero. A stiffener is a thicker piece added behind the pad area. It makes the insertion stable. FR-4 stiffeners are common. Polyimide stiffeners are used when you still need some flex.

On real builds, the pad wear shows up fast without a stiffener. I have seen field returns caused by pad cracking near the connector. The root issue was over-bending at the connector edge. A longer stiffener and a better strain relief fixed it.

- Base film is usually polyimide. It handles heat well.

- Coverlay protects traces. It leaves pads exposed.

- Stiffeners improve insertion life and reduce pad stress.

Choosing the right FPC cable connector

The connector is where many projects fail. The pitch must match the cable pads. The contact side must also match. Some connectors are “top contact.” Others are “bottom contact.” If you guess, you will re-spin a board.

ZIF connectors are popular. ZIF means “zero insertion force.” A latch opens, the cable slides in, and the latch closes. That reduces pad damage. Non-ZIF styles exist too. They can be fine for permanent builds. They are risky for lab churn.

Pay attention to how the latch works. Flip-lock and slide-lock styles behave differently. I have watched an operator break a flip-lock latch with too much force. Training solved that. A simple label on the assembly fixture also helped.

Ask for the connector’s recommended FPC thickness range. Many designs assume 0.3 mm. Some are 0.2 mm. Your stiffener changes the effective thickness. This matters for clamp force and contact resistance.

Table: Key connector checks before you release a PCB

| Pitch | Connector pitch matches FPC pad pitch | The wrong side creates open circuits |

| Contact side | Top vs bottom contact matches exposed pads | Wrong side creates open circuits |

| Cable thickness | FPC + stiffener thickness fits connector spec | Bad fit causes high resistance or latch failure |

| Pin count | Total contacts match the pinout | Wrong count blocks assembly or shifts signals |

| Insertion direction | Cable entry angle and keep-out on PCB | Tight space can force a bend and crack pads |

Common FPC cable types you will see in real products.

Engineers ask for “an FPC cable,” but there are many variants. Some are single-layer. Some are double-layer. Some include shielding. Some include impedance-controlled traces for high-speed links. The mechanical outline also varies a lot.

One common split is static flex versus dynamic flex. Static flex means it bends once during assembly. It stays in place after. Dynamic flex means it bends many times in use. Foldable devices and moving sensor arms fall into this category.

You will also see special end treatments. Gold plating is common on contact fingers. That is usually electrolytic hard gold for wear resistance. ENIG is used on solder pads, but it is not always ideal for edge fingers. The right finish depends on the connector mating cycles and cost.

If you need a custom flex, request a drawing with key notes. Include bend lines, stiffener zones, and contact side marking. That avoids “mirror image” mistakes.

- Single-layer FPC for simple links and low cost.

- Two-layer FPC for crossovers and better return paths.

- Shielded FPC for noise control in tight RF spaces.

- Dynamic flex FPC for repeated motion. Bend design is critical.

How to connect an FPC cable without damaging it

You might wonder why this needs a section. It does because most connector damage is human-caused. The parts are small. The latches are fragile. The pad area is easy to crease.

Here is the method we teach on the factory floor. The steps also work in a lab.

- Power off the device. Discharge any stored energy.

- Open the latch using the correct motion. Do not pry hard.

- Align the cable straight. Do not insert at an angle.

- Insert to the stop. Use the alignment marks if present.

- Close the latch gently. Feel for a clean snap or slide.

- Do a light pull test. The cable should not slip out.

ESD control matters too. Use a grounded mat and wrist strap when possible. Many FPCs carry sensitive camera signals. A small ESD hit can show up as a ghost fault later.

When the design allows it, add strain relief. A small foam pad or a clamp feature helps. It reduces peel force on the connector during drops.

FPC cable Raspberry Pi use: CSI and DSI realities

The Raspberry Pi ecosystem makes FPCs feel “standard.” Yet the details still matter. The camera and display links typically use CSI and DSI connectors. Those are high-speed serial links. Signal integrity matters. Cable length and routing matter too.

On Raspberry Pi boards, the cable orientation can be confusing. Some connectors expect contacts facing in. Others expect contacts to face out. The safest move is to check the connector type and the cable’s exposed pad side. Do not rely on photos from a different board revision.

People often ask about an FPC cable Raspberry Pi extender. Extenders can work for short runs. Yet longer cables can increase loss and noise. The exact limit depends on the interface speed and cable design. I avoid making a hard promise without measurements. A quick eye diagram test tells the truth.

If you are moving to a new platform, you might also search for fpc cable raspberry pi 5 compatibility. The connector pitch and placement can differ by model. Always read the board’s official hardware notes. Also, verify the cable pinout. This avoids swapped lanes and dead peripherals.

- Confirm the connector contact orientation on your exact Pi model.

- Keep high-speed flex runs short when you can.

- Validate with testing if you must extend the link.

FPC cable repair: what is realistic, and what is risky

Teams often ask for quick fpc cable repair. I understand why. A custom flex can have a lead time. A prototype schedule is not flexible. Still, repair has limits.

Minor issues can sometimes be handled. A dirty contact can be cleaned with high-purity isopropyl alcohol. A loose stiffener can sometimes be re-bonded with the correct adhesive system. These are controlled actions. They must be documented.

Trace breaks are harder. Jumpers can be added under a microscope. Yet the flex area will not like it. The repair often fails when bent. I have seen “fixed” cables pass on the bench and fail after one assembly cycle. That is why I treat jumper repairs as a debug tool only. They are not a production solution.

Connector damage is also common. If a ZIF latch is broken, replacement is usually the right move. Some latches can be swapped. Many cannot. The cost of a second failure is usually higher than a new part.

- Cleaning contacts is low risk when done correctly.

- Jumper repairs can help debug. They rarely survive long-term motion.

- Broken latches usually mean connector replacement.

Quality control that actually catches flex cable problems

Flex cables fail in ways that are easy to miss. Visual defects can hide under coverlay edges. Pad contamination can look fine. A pinout error looks perfect until power-up.

For bare FPC fabrication, IPC-A-600 is often used as an acceptance reference for printed boards. For assemblies, J-STD-001 and IPC-A-610 guide solder quality. Not every clause maps perfectly to flex. Still, auditors and customers often expect these standards in a quality system.

On the shop side, a basic electrical test is critical. Continuity and isolation tests catch opens and shorts. Dimensional checks catch outline drift. If the cable mates to a tight connector, the pad length and stiffener placement must be controlled.

When we quote flex builds at WellCircuits, we ask early questions about mating cycles and bend zones. That is not sales talk. It prevents returns. A small drawing note can change the yield.

Table: QC checkpoints for FPC cables and why they matter

| Incoming materials | Film and copper lot traceability | ISO 9001 quality systems | Mixed materials and unstable process results |

| In-process | Coverlay alignment and openings | Work instructions and drawings | Exposed copper or blocked pads |

| Final inspection | Pad plating and surface cleanliness | IPC-A-600 as a common reference | High contact resistance and early wear |

| Electrical test | Continuity and isolation | Customer netlist and test plan | Opens, shorts, swapped nets |

| Assembly audit | Connector mating and latch function | IPC-A-610 intent for workmanship | Intermittent faults in system test |

Sourcing and DFM: what to send your flex supplier

The fastest flex projects start with clean inputs. Many delays are caused by missing notes. The fab house then asks questions. The schedule slips. The buyer gets surprised.

Send a proper data pack. Gerbers are not enough for a flex. Include the stackup, coverlay rules, and stiffener callouts. Include the connector part number if you can. It sets the pad geometry and thickness target.

DFM feedback should be expected. A good supplier will flag tight pad spacing, small radii, and unclear bend zones. IPC-2223 gives guidance, but the factory process window matters too.

Here is what I ask for when the goal is low risk and fast yield.

- Fabrication drawing with units and tolerances.

- Stackup note, including copper weight and coverlay thickness if known.

- Stiffener material, thickness, and adhesive type callout.

- Contact finish requirement for edge fingers, if mating cycles are high.

- Connector part number and contact orientation notes.

If you need a fast sanity check, ask your supplier to build a mating sample. A simple fit test can prevent a full re-spin. I have seen this save weeks on camera module launches.

FAQ

What is the fpc cable full form?

FPC stands for Flexible Printed Circuit. It is a printed circuit built on a flexible film. The copper traces are etched like a PCB. The ends have exposed pads that mate with a connector. The design is often custom for one product.

What is the FPC cable’s meaning in manufacturing terms?

In manufacturing, an FPC is a flex circuit that is made with film, copper, coverlay, and often stiffeners. It is not just a wire harness. It is treated like a PCB process with imaging, etching, and testing. The mechanical outline is also part of the functional design.

How do I choose an fpc cable connector?

Match pitch, pin count, and contact side to the cable pads. Confirm the connector supports your cable thickness with a stiffener. Pick a latch style that fits your service needs. ZIF styles reduce pad wear during rework. Always check the keep-outs so the cable can enter straight.

Can I do fpc cable repair on a torn flex?

Sometimes, but it is risky. Cleaning and minor re-bonding can work. Trace repair with jumpers can help with debugging. It often fails with bending or vibration. For production, replacing the flex is usually safer. If the cable carries high-speed signals, repair can also hurt signal quality.

Which FPC cable is used for the Raspberry Pi camera or display?

Many Raspberry Pi camera and display links use CSI or DSI FPC cables. The cable must match the connector pitch and contact orientation. Do not assume all Pi models use the same cable. Check the board documentation and the connector type. A reversed cable is a very common bring-up issue.

Is an FFC the same as an FPC?

No. An FFC is a flat cable made from parallel conductors. It often provides a simple 1:1 connection. An FPC is a printed circuit on flexible film. It can support complex routing and custom shapes. Both can look similar at a glance. The internal construction is different.

Conclusion

FPC cables solve problems that rigid boards cannot. They fit tight spaces and enable clean layouts. Yet they demand careful handling and clear specs. Most “mystery” failures are basic. The cable was flipped, the latch was damaged, or the contact side was wrong.

Think about the full system before you lock the design. Match the connector to the cable thickness. Mark the contact side on the drawing. Use IPC-2223 guidance for bend zones when flex life matters. If you want a second set of eyes, share your stackup and connector details with a qualified team. WellCircuits can review your flex package and flag common risks before you build. That step often costs less than one re-spin.