Flux Cleaning Methods for Circuit Boards

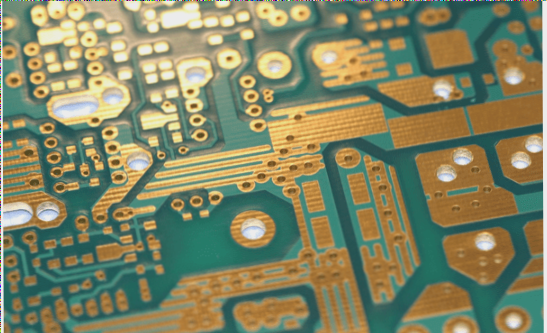

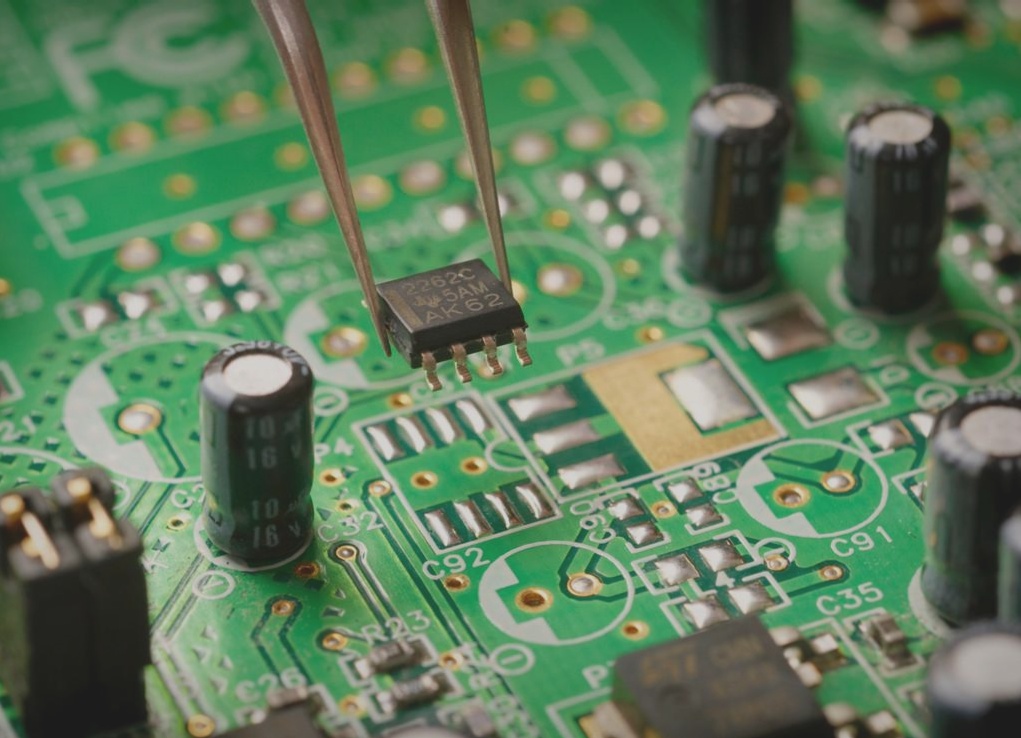

When manufacturing circuit boards, flux is commonly used to enhance electronic component connections. However, cleaning flux after application is crucial for the proper operation of the circuit board.

Types of Flux

- Solid Flux

- Liquid Flux

- Paste Flux

Methods of Cleaning Flux

- Traditional Cleaning: Involves solvents or cleaning fluids, but may leave residue affecting performance.

- Dry Ice Cleaning: Uses dry ice particles for residue-free cleaning.

- Water Washing: Simple and cost-effective, but may cause damage to PCBs.

- Solvent Cleaning: Efficient but requires careful handling due to safety concerns.

- Ion Cleaning: High-tech method using ion beams for effective cleaning.

Characteristics of Cleaning Agents

Cleaning agents for flux should:

- Efficiently remove flux residues without damaging the circuit board.

- Have anti-corrosion properties to prevent copper corrosion.

- Have a broad application range for different types of circuit boards.

Flux cleaning agents are essential for electronic manufacturers to ensure the quality and stability of circuit boards during production.