Quick Turn Rigid Flex PCB Manufacturing in China

Introduction

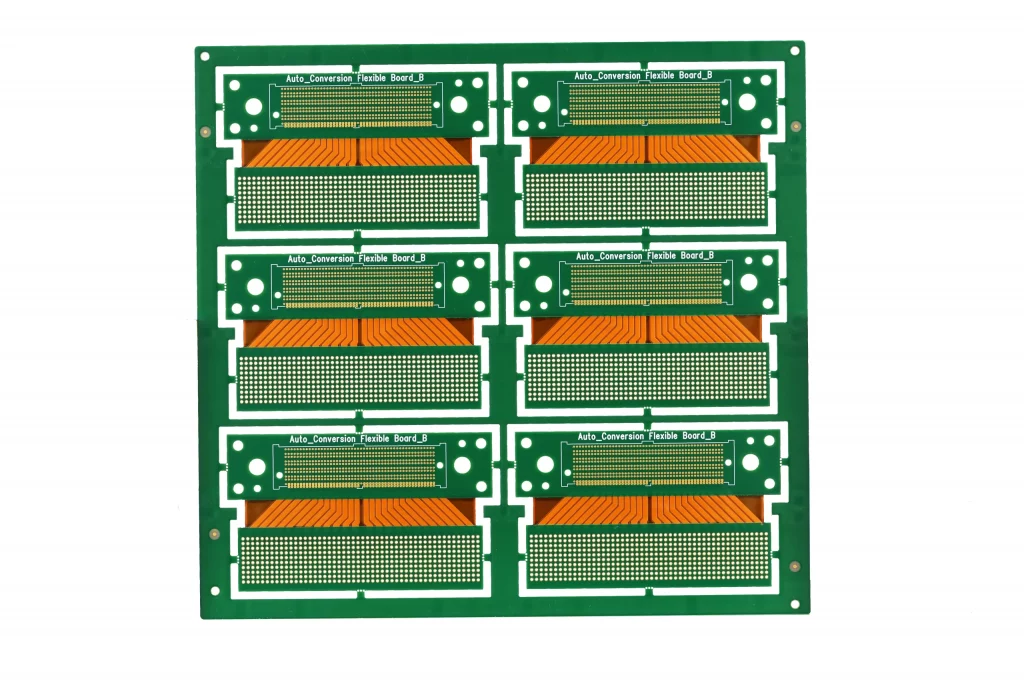

The rapid evolution of modern electronics demands compact, lightweight, and highly efficient solutions, particularly in the realm of polyimide flex materials. Enter flex PCBs (flexible printed circuit boards), an innovative technology revolutionizing circuits’ design and integration. As businesses strive to adopt this cutting-edge solution, China has emerged as a global leader in rigid-flex PCB fabrication, particularly in flexible materials technology. flex PCB manufacturing, including advanced pcb prototyping techniques. Offering unmatched expertise in flexible materials and circuits, a reputable PCB manufacturer provides scalability and competitive pricing for PCB assembly services.

If you’re exploring rigid flex PCBs considering the importance of quick turn PCBs in today’s market, flexibility in design is key. Quick turn flex PCBs, or aiming to source quick turn rigid flex This guide covers everything you need to know about quick turn PCB services and flexible circuit options, including design tips for optimal performance in volume production. flex PCB PCB assembly is a critical step in the manufacturing process for rigid-flex printed circuit boards in China, particularly for quick turn projects. Learn about their uses, advantages, and why partnering with a Chinese manufacturer could give your business a competitive edge.

What Are Flex PCBs?

A flex PCB is a type of printed circuit board designed to be flexible, enabling it to bend, fold, or twist. Unlike traditional rigid PCBs, polyimide flex PCBs are made of materials that can withstand both mechanical stress and extreme temperatures while maintaining functionality.

Applications of Flex PCBs include rigid-flex printed circuit boards and quick-turn flex circuits, which are essential for efficient circuit fabrication.

- Consumer Electronics are increasingly utilizing rigid-flex printed circuits for enhanced performance and durability. (smartphones, wearable devices) are increasingly incorporating flexible circuits to enhance functionality.

- The automotive industry increasingly relies on rigid-flex printed circuit boards for their lightweight and efficient designs. (in dashboards, ADAS systems, and flexible circuits, including rigid-flex circuit applications and HDI technology).

- Medical Devices: Portable health monitors, diagnostic tools, and rigid-flex boards are examples of applications benefiting from advanced PCB capabilities.

- Aerospace equipment often utilizes rigid-flex printed circuit boards due to their durability and performance in extreme conditions. (navigation systems, communication devices)

Flex PCBs stand out for combining functionality and versatility, making them essential in industries where space constraints and weight minimization are critical.

Rigid Flex PCBs vs. Flex PCBs

Although flexible circuits offer many advantages, careful consideration is needed during the PCB fabrication process. flex PCBs and rigid flex PCBs. Flexible PCBs and rigid-flex circuits share similarities; understanding their differences can help you choose the right option for your application, whether it be a flex PCB design or a rigid-flex circuit.

Flex PCBs

- Flexible OnlyEntirely flexible, designed for dynamic environments with constant bending, the rigid-flex board offers unique advantages in production quantities.

- Used in Dynamic Applications, such as quick turn flex circuits and rigid-flex printed circuit boards.Ideal for areas requiring frequent motion or vibrations, such as foldable smartphones, rigid-flex PCBs provide quick turn solutions.

- Cost-Effective for Simpler Needs in PCB assembly can be achieved with flexible circuit options, particularly in rigid-flex designs.

Rigid Flex PCBs

- Combination of Rigid and Flexible LayersOur designs offer the flexibility of flex PCBs in specific areas while retaining durability in rigid sections, ideal for rigid-flex PCB manufacturing.

- Perfect for Complex Designs: Commonly used in high-precision devices like medical and aerospace systems.

- Robust and long-lasting, polyimide flex materials are essential in the manufacturing of high-performance flexible circuit boards, particularly in FPC applications for volume production.

For more intricate designs requiring mechanical stability, quick-turn rigid flex PCBs provide the versatility you need. Think of them as a “best of both worlds” solution, combining the benefits of rigid circuit boards and flexible designs.

Why Choose China for RIGID Flex PCB Manufacturing?

China is globally recognized as the hub for electronics manufacturing, and the flex PCB Production of rigid-flex PCB fabrication is no exception. Here’s why sourcing from China makes strategic sense for your circuit fabrication needs:

1. Cost Efficiency Without Compromising Quality

Chinese manufacturers leverage an extensive supply chain and advanced production techniques to deliver high-quality flex PCBs at competitive pricing, establishing themselves as leading flex PCB manufacturers.

2. State-of-the-Art Technology

China boasts some of the most sophisticated manufacturing facilities for producing flexible circuits and rigid-flex PCBs, ensuring high production quantities. Rigid flex PCBs, ensuring adherence to global standards and seamless innovation in PCB fabrication, particularly in HDI applications.

3. Quick Turn Flex PCB Production

Need your PCBs fast? Consider our quick-turn PCB and flexible circuit services for rapid delivery and fast turnaround. Many manufacturers in China specialize in flex PCB fabrication, providing quick turn options for clients. Quick-turn flex PCB and quick-turn rigid-flex PCB solutions are essential for modern electronics, especially when you need a quick turnaround for production runs. rigid flex PCB Production of quick turn prototype PCBs meets tight deadlines without sacrificing quality.

4. Customization

Manufacturers in China offer customizable solutions tailored to unique business needs, including flexible PCBs and quick turn PCB options, ensuring efficient lead times with high-quality FR4 materials. Whether you need specific materials, stack-up designs, or additional features for your rigid-flex board, they can deliver.

5. Experienced Workforce

With decades of expertise in PCB design and manufacturing, Chinese firms employ skilled engineers and technicians to ensure precision and reliability in rigid-flex PCBs.

6. Global Shipping and Logistics Expertise

Chinese manufacturers are well-versed in handling international shipments, adhering to import regulations and ensuring timely delivery.

Key Steps in Quick Turn RIGID Flex PCB Manufacturing

Flex PCB manufacturing PCB fabrication is a meticulous process requiring precision and attention to detail, especially in quick-turn prototype scenarios. Here’s a high-level breakdown of the manufacturing steps followed by top manufacturers in China for rigid-flex boards.

1. Design & Layout

The process begins with designing the PCB layout based on customer specifications for rigid-flex PCBs, ensuring optimal space usage and functionality while utilizing flexible materials.

2. Material Selection

High-quality materials, such as polyimide and copper, are procured to guarantee flexibility, heat resistance, and durability in our flex and rigid-flex PCB offerings.

3. Etching

Chemical etching is used to define the copper traces that serve as pathways for electrical signals in quality flex circuits.

4. Drilling

Advanced laser drilling techniques are used to create vias that connect various layers of the rigid-flex PCB.

5. Lamination

For rigid flex PCBs, flexible and rigid layers are laminated together to achieve the desired structure.

6. Surface Finish Application

Protective coatings are added to prevent oxidation and ensure reliable soldering. Common finishes for flexible circuits include ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling) to ensure quality flex performance.

7. Electrical Testing

Continuity and functionality tests check for defects and ensure all circuits function as intended.

8. Final Assembly & Quality Control

Each PCB undergoes rigorous quality assurance checks before being packaged and shipped, ensuring the highest standards for flex PCB manufacturing and quick turn capabilities.

How to Choose the Right Manufacturer in China

Finding the right supplier for your quick-turn flex circuit and rigid-flex printed circuit board needs is essential for project success. flex PCB or quick turn rigid flex PCB. Understanding your project’s needs is critical to your success in choosing a circuit board manufacturer that specializes in flex PCB fabrication. Here are some tips to guide your decision-making process regarding rigid-flex PCBs for new product introduction:

- A reputation as a leading flex and rigid-flex PCB manufacturer is essential for ensuring high-quality flexible circuits.: Look for manufacturers with a proven track record and positive reviews from global clients.

- Certifications are essential for ensuring the quality and reliability of flexible circuit products, especially in high-volume production runs.: Ensure the firm complies with ISO, RoHS, and other global quality standards in PCB assembly.

- Customization Capabilities for flex and rigid-flex designs are essential in meeting diverse client needs.: Verify whether the manufacturer can handle specific requirements and offer personalized support.

- Engineering Support for flexible PCB designs and quick turn PCB services.: A reliable supplier should provide expertise in design optimization and technical troubleshooting.

- Turnaround Time for prototype development is crucial in the fast-paced electronics market, especially when utilizing quick-turn PCBs and rigid-flex PCBs for new product introduction.Time is critical, especially for quick-turn projects that demand efficient production quantities. Check their manufacturing and shipping timelines.

The Future of Flex PCB Manufacturing in China

With increasing demand for compact and high-performance electronics, China’s flexible circuit manufacturing capabilities, especially for rigid-flex circuit solutions, are unmatched due to their advanced manufacturing equipment. flex PCB and rigid flex PCB manufacturing industry will continue to thrive. Innovations in materials, automation, and AI-assisted production are expected to further boost efficiency and cost-saving measures, making China the go-to destination for global businesses.

How to Get Started

If you’re ready to explore the reliability and affordability of flex PCBs, partnering with a Chinese manufacturer is your best bet. By choosing the right supplier, you’ll maximize efficiency, reduce costs, and stay competitive in today’s fast-paced market.

At Well Circuits, we specialize in connecting businesses with trusted, high-quality rigid-flex printed circuits. flex PCB solutions from leading manufacturers in China. Whether you need Quick-turn flex PCBs made from polyimide material is increasingly in demand. Or rigid flex PCBs. For your project, our expert team is here to help with circuit fabrication and provide quick turn solutions.

Contact us today for a free quote on our flexible circuit solutions and stay ahead of the curve in flex and rigid-flex PCB manufacturing.