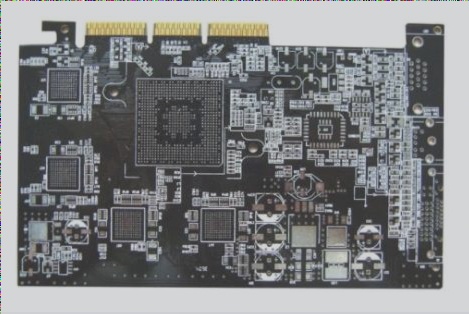

Copper Sulfate Electroplating in PCB Manufacturing

Copper sulfate electroplating plays a critical role in the production of PCBs. The quality of acid copper electroplating directly impacts the mechanical properties of the copper layer on PCB boards, influencing subsequent processing steps.

Challenges in Acid Copper Electroplating

- 1. Rough plating

- 2. Copper particles on the board surface

- 3. Electroplating pits

- 4. Whitish or unevenly colored board surfaces

Solutions to Common Issues

Addressing these challenges is crucial for efficient PCB manufacturing:

Rough Electroplating

Excessive electroplating current can lead to a rough board surface. Monitoring and adjusting the current, along with regular inspections, can help resolve this issue. Environmental factors like low temperatures and chemical composition can also impact the plating quality.

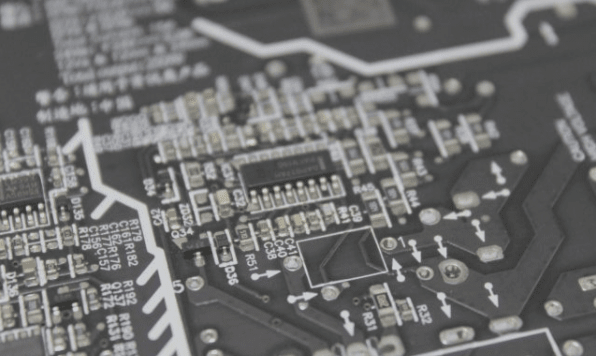

Plating Copper Particles

Copper particles on the board surface can result from various factors, including process variations and material quality. Proper monitoring and control of the plating process can minimize these particles and improve surface quality.

Dissolving or Accelerating Issues

Turbidity in the bath solution can indicate underlying issues such as chemical reactions or contamination. Maintaining proper chemical balance and cleanliness in the plating tanks is essential to prevent particle formation and ensure consistent plating quality.

Graphics Transfer Process

Issues like oxidation and contamination during the graphics transfer process can affect the final board quality. Implementing thorough cleaning procedures and environmental controls can help mitigate these problems and enhance overall production efficiency.

Conclusion

By addressing these common challenges in acid copper electroplating, PCB manufacturers can enhance the quality and reliability of their products, leading to improved performance and customer satisfaction.