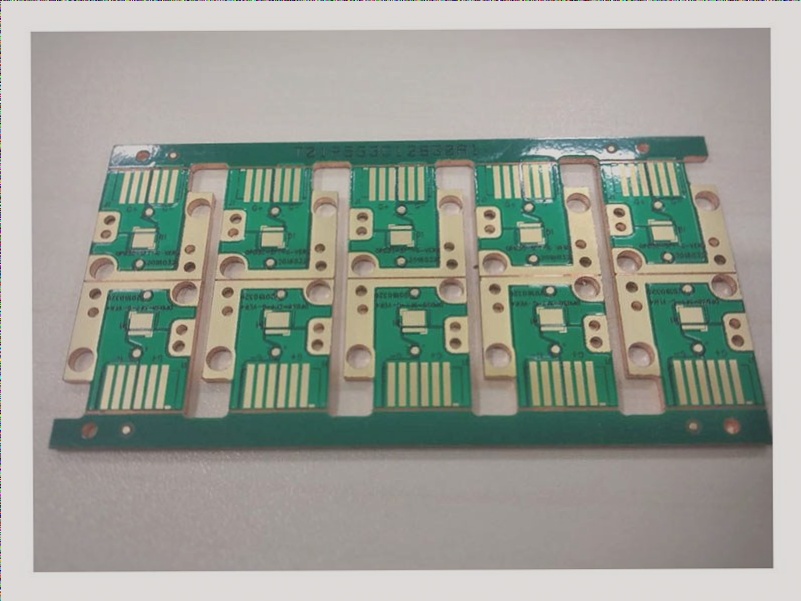

PCB Plug-in Component Pads Proofing Guidelines

When proofing PCB plug-in component pads, it is essential to consider the appropriate pad sizes to ensure successful soldering. Here are some key points to keep in mind:

- Excessively large pads can lead to incomplete solder joints due to increased solder spreading area.

- Too small pads may result in non-wetting solder joints due to insufficient surface tension of the copper foil.

- Ensure the gap between the aperture and the component lead is within the ideal range for optimal soldering conditions.

PCB Proofing Process Requirements

During the PCB proofing process, it is crucial to adhere to specific pad requirements to maintain quality standards:

- Include test pads for all nodes following ANSI/IPC2221 standards.

- Each test pad should contain the node signal name, x-y coordinates, and the specific position on the PCB.

Considerations for PCB Proofing

When it comes to PCB proofing, the pad aperture size plays a critical role in the overall reliability and functionality of the circuit board. Here are some essential considerations:

- The aspect ratio of plated through holes significantly impacts the effectiveness of plating within the hole.

- Ensure the ratio of the circuit board’s thickness to the pitch of plated through holes is less than 5:1.

- Information on fixed equipment for SMT and warming technology in PCB assembly layout is essential for circuit development.

Following these guidelines will help enhance the quality and reliability of PCBs during the proofing process.