Common Issues with SMT Chip Processing Plants and Preventive Measures

- Insufficient melting of flux paste during soldering can be a common issue in some SMT chip processing plants.

- Causes and preventive measures for this issue:

-

1. Inadequate Flux Melting on PCB Solder Joints:

When solder joints on the PCB show insufficient flux melting, it may be due to low peak temperature or short reflow time.

Preventive measures: Adjust the temperature profile to set the peak temperature 30-40 degrees Celsius higher than the flux melting point and ensure a reflow time of 30-60 seconds.

-

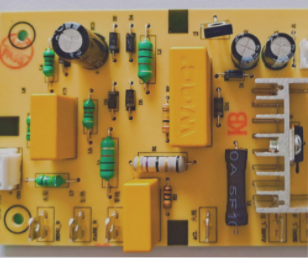

2. Uneven Temperature in Reflow Soldering Furnace for Large Boards:

Insufficient flux melting on both sides of large-size SMT circuit boards may indicate uneven temperature in the reflow soldering furnace.

Preventive measures: Increase peak temperature, extend reflow time, and position the board in the center of the furnace.

-

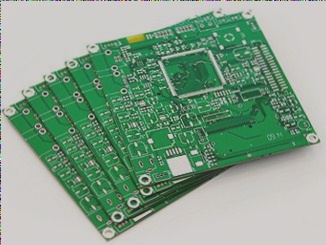

3. Insufficient Solder Paste Melting at Fixed Positions:

Issues with large solder joints or components can lead to insufficient melting due to excessive heat absorption or hindered heat conduction.

Preventive measures: Place large components on the same side of the SMT circuit board and adjust peak temperature or reflow time as needed.

-

4. Variations in Infrared Furnace Soldering:

Differences in device color and size can result in varying temperatures on the same circuit board during infrared furnace soldering.

Preventive measures: Increase soldering temperature to ensure uniform heating for all components.

-

5. Quality of SMT Flux Paste:

Issues can arise from using flux paste with high oxygen content or improper handling, such as condensation from low-temperature storage.

Preventive measures: Use high-quality solder paste within its validity period, avoid mixing recycled paste with new paste, and handle paste properly to prevent moisture absorption.