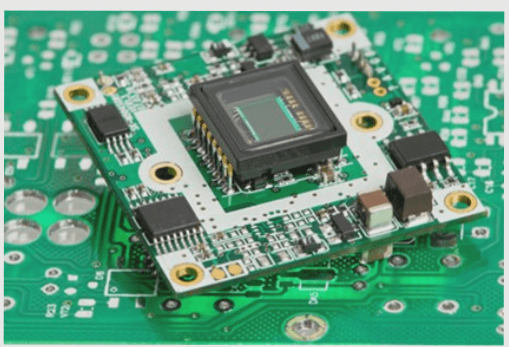

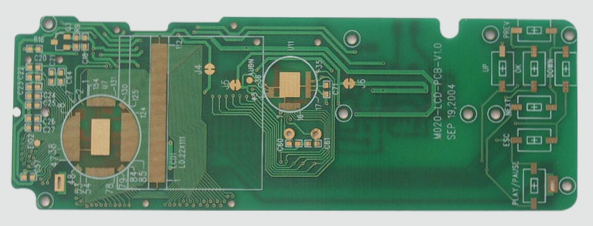

PCBA Pollution: Understanding Contaminants and Their Impact

Primary Sources of Contamination:

- Components and oxidation of the PCB

- Residues from flux during manufacturing

- Marks from handling and welding

- Workplace pollutants like dust and solvents

The Impact of Pollution:

Contamination can lead to:

- Corrosion of PCBA

- Electromigration causing short circuits

- Reduced coating effectiveness

- Coating cracks and reliability issues

Typical PCBA Failure Problems Due to Contamination:

- Corrosion: Leads to circuit failures

- Electromigration: Causes dendritic growth and short circuits

- Poor Electrical Contact: Increases contact resistance

The Necessity of Cleaning:

- Appearance and Electrical Performance Requirements: Residues affect appearance and performance

- Three-proof Coating Requirements: Cleaning improves coating adhesion

- Even “No-Clean” Assemblies Require Cleaning: Residues impact reliability and safety

It’s crucial to address PCBA contamination to ensure optimal performance and reliability.