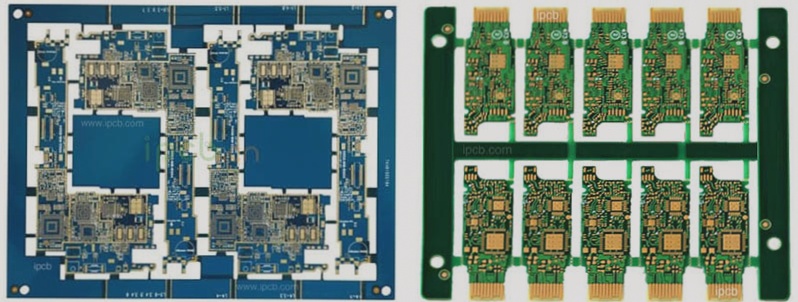

The Importance of Secure PCB Fixation in Mass Production

In mass PCB production, ensuring the proper application of solder paste is crucial for product quality. Automatic printing machines are commonly used for this process, but the method of stabilizing the PCB within the machine can significantly impact the final result.

Challenges with Conventional Methods

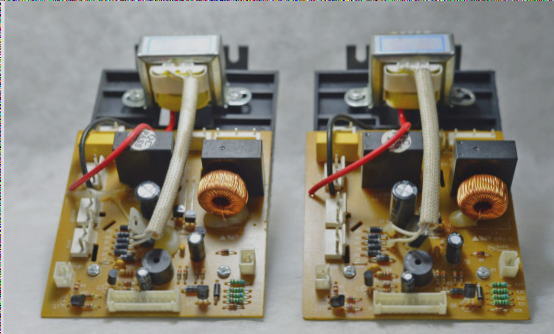

- Clamping Force Issues: Traditional methods of stabilizing PCBs can lead to clamping forces that cause bulging in the center, resulting in uneven solder paste coating.

- Risk of Breakage: Thin and fragile PCBs are particularly susceptible to damage during the stabilization process.

Improved Solution: Vacuum Suction Fixation

Utilizing vacuum suction for PCB fixation offers several advantages:

- Prevents Bulging: By eliminating opposing forces on the PCB’s sides, vacuum suction ensures a flat surface for even coating.

- Enhanced Stability: The use of a custom platform within the vacuum suction device provides additional support, reducing the risk of breakage.

Enhancing Placement Process

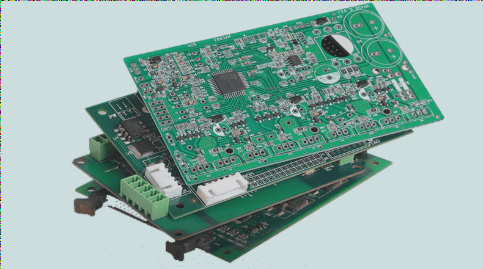

Securing PCBs during the placement process is critical for maintaining product quality:

- Custom Tray Solution: Using custom trays for PCB transportation minimizes the risk of deformation and breakage during placement.

- Simplified Pallet Design: Implementing vacuum adsorption in pallet design simplifies manufacturing and improves stability during handling.

Future Considerations

Exploring innovative solutions, such as integrating vacuum devices into existing machinery, can further enhance PCB stabilization and improve production efficiency.