The Evolution of SMT Welding Technologies: Automated vs. Manual Perspectives

Introduction: The Shift from Manual to Automated Soldering Solutions

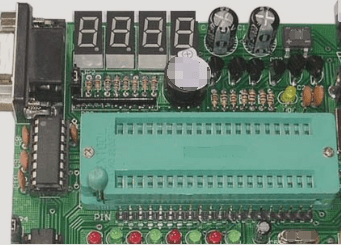

As global demand for high-quality electronic products surges, traditional manual soldering techniques using soldering irons for PCB board pin joints are becoming increasingly obsolete. This comprehensive guide examines the transition to automated soldering solutions, analyzing how they enhance production efficiency and product reliability in international electronics manufacturing.

Historical Development of Automated Welding Technologies

The Emergence of Automatic Welding Machines

With the scaling of electronic production, manufacturers introduced:

- Semi-automatic mass soldering equipment

- Fully automatic welding machines

- Advanced wave soldering systems

Originally developed in Japan, these automated welding solutions first served as primary production equipment for television manufacturing before expanding into broader electronics applications.

Introduction to China’s Manufacturing Landscape

During the 1980s, China adopted these advanced welding technologies, including:

- Dip soldering machines

- Single wave soldering machines

- Double wave soldering systems (following SMT technology advancements)

Flow Soldering Technology Explained

This automated soldering method encompasses:

- Dip soldering

- Single-wave soldering

- Double-wave soldering

“Flow soldering technology revolutionized PCB assembly by enabling precise, consistent solder joints through controlled movement between molten solder and workpieces.”

Advantages of Automated Flow Welding

Compared to manual patch welding, automated flow welding offers:

- 30-50% energy savings

- Reduced labor requirements

- Enhanced production efficiency

- Lower manufacturing costs

- Improved product consistency

- Elimination of human error factors

Versatility in Modern Manufacturing

Today’s automatic soldering machines from leading manufacturers in China can accommodate various tooling configurations to meet diverse PCB assembly requirements, making them ideal for:

- High-volume production

- Complex circuit board assemblies

- Precision component soldering

SMT Manual Welding: Traditional Techniques in Modern Manufacturing

The Skilled Welding Process

Experienced technicians can:

- Adjust torch position in real-time

- Modify welding posture

- Control walking speed visually

This manual welding expertise remains valuable for certain applications despite automation advances.

Limitations of Manual Methods

Key challenges include:

- Inconsistent operator skill levels

- Variable production speeds

- Quality fluctuations due to human factors

- Limited daily output capacity

Strategic Advantages of Manual Placement

While automated SMT solutions dominate mass production, manual methods offer unique benefits:

Flexibility for Specialized Applications

- Ideal for small batch prototypes

- Faster turnaround for samples

- No tray loading requirements

Cost-Effective for Certain Projects

- Eliminates machine programming costs

- No material preparation expenses

- Reduced startup costs

Quality Assurance Processes

Manual welding incorporates:

- Magnified visual inspections

- Precision BGA alignment systems

- Hands-on quality verification

Conclusion: Choosing the Right Welding Approach

This analysis of SMT welding technology evolution demonstrates that both automated and manual methods have distinct roles in modern electronics manufacturing. While automated soldering machines excel in high-volume production, manual techniques remain valuable for specialized applications requiring flexibility and precision.

For businesses seeking reliable PCB assembly solutions, understanding these technological differences is crucial when selecting manufacturing partners in China or other global production hubs.