The Intricacies of Printed Circuit Board (PCB) Etching

The creation of printed circuit boards (PCBs) involves a series of intricate physical and chemical reactions, with the “graphic electroplating method” being the primary technique used in PCB processing. This method entails depositing a lead-tin corrosion-resistant layer onto copper foil, followed by selective chemical etching to reveal the desired circuitry.

Types of PCB Etching

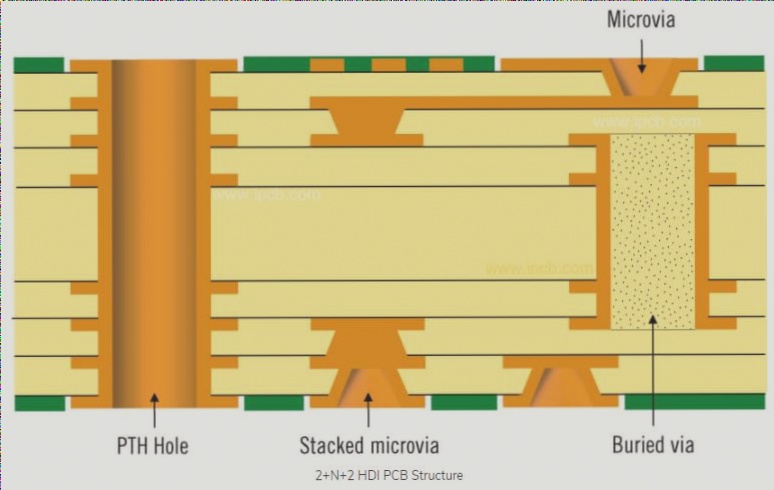

- Outer Layer Etching: Involves etching one layer of copper while preserving the final circuit layout, often utilizing a copper plating layer beneath the resist layer.

- Full Board Copper Plating: Requires plating the entire PCB surface with copper, posing challenges during etching, particularly with fine wire widths and potential side corrosion issues.

- Photosensitive Film Method: Utilizes photosensitive film as a corrosion-resistant layer in outer circuit PCB processing, akin to inner layer etching processes.

Current Trends and Challenges

Presently, tin or lead-tin resist layers are commonly paired with ammonia-based etchants due to their non-reactivity. However, sulfuric acid hydrogen peroxide, while explored, faces limitations in commercial adoption due to economic and waste management concerns.

Etching Quality and Challenges

Ensuring high-quality etching involves complete copper removal under the resist layer, managing conductor linewidth consistency, and minimizing side corrosion. Issues like side etching width and depth ratios, equipment design, and additive use impact etching quality.

Key Concerns in PCB Etching

- Side Etching: Debated extensively, with a preference for minimal side etching to maintain quality.

- Equipment Design: Influences etching factors and side corrosion extent, with proprietary additives aiding in corrosion mitigation.

- Process Interconnectedness: Problems in earlier fabrication stages can affect etching quality, emphasizing the need for meticulous process control.

Challenges in Graphic Electroplating

Issues such as the “inverted stream” effect, edge formation, and incomplete etching due to residual glue or film remnants highlight the complexities of PCB processing and the importance of precise execution at every stage.

Improving PCB Etching Processes for Enhanced Quality and Efficiency

Chemical reactions and residue accumulation in corrosive solutions can hinder etching processes, impacting production efficiency. Equipment adjustments and proper interaction with corrosive solutions are crucial for maintaining consistent etching quality.

Effective etching relies on continuous contact between the metal surface and fresh etching solution to flush out copper ions and provide necessary reactants like ammonia. Control over copper ions significantly influences etching rates, with techniques such as aeration helping manage ion levels.

Research in chemical etching, including photochemical etching (PCH), explores alternative solutions like divalent copper for stricter control parameters, potentially enhancing PCB fabrication methods.

Understanding the differences in etching states between the upper and lower plate surfaces is essential for addressing quality issues. Colloidal structures formed by the etchant on the upper plate surface can impact etching speed and result in varying degrees of etching across the printed circuit board.

Maintaining etching equipment involves ensuring clean, unobstructed nozzles to prevent uneven etching and wastage. Regular replacement of damaged parts, especially the nozzles, is crucial. Preventing excessive slagging buildup is also necessary to maintain the chemical balance of the etching solution.

Residual film and incomplete removal of previous films can contribute to slagging issues, emphasizing the importance of thorough cleaning and solution composition adjustments.