Preventing PCB Bending and Warping in Reflow Furnace Processing

Effective Strategies to Maintain PCB Integrity

- Minimizing Temperature Impact on PCB Stress

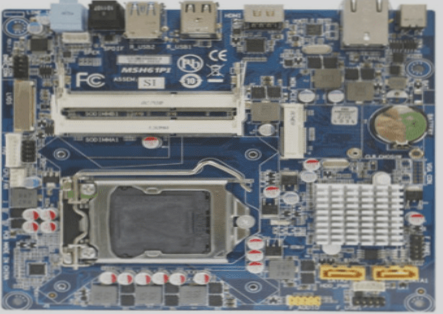

- Choosing High Tg Materials

- Optimizing Circuit Board Thickness

- Reducing Board Size and Panels

- Utilizing Furnace Tray Fixtures

- Using Routing Instead of V-Cut for Sub-boards

Controlling reflow oven temperature and heating/cooling rates can reduce bending and warping risks.

Utilizing materials with higher glass transition temperatures enhances PCB resilience against deformation.

Consider using a 1.6mm thickness to prevent bending and deformation issues during reflow.

Orient boards along the reflow furnace chain edge to minimize weight-related deformation.

Reflow carriers and templates can support PCBs during thermal expansion, reducing bending risks.

Avoid V-Cut techniques to maintain panel integrity between circuit boards.

If you require PCB manufacturing services, feel free to contact us.