Understanding EMI (Electro-Magnetic Interference)

EMI, short for Electro-Magnetic Interference, is a phenomenon where disturbances impact circuits on printed circuit boards due to electromagnetic induction, electrostatic coupling, or conduction. These interferences can lead to performance degradation of PCB components, data corruption, or even component malfunction.

The Importance of EMI Shielding Film in FPCs and Rigid-Flex PCBs

EMI shielding plays a crucial role in electronic devices by safeguarding signals from external electromagnetic interference and preventing interference with surrounding components. It is essential to use specific materials and manufacturing techniques for EMI shielding to maintain the integrity of signals within the device.

As the use of wireless communication devices like smartphones and wireless printers increases, the need for EMI shielding becomes more critical. External interference can affect electronic devices, making the application of EMI shielding vital for maintaining performance and reliability.

When designing flexible PCBs or rigid-flex PCBs, incorporating EMI shielding is necessary to reduce electromagnetic or electrostatic interference. Factors such as the number of EMI interfaces, conductivity requirements, and circuit flexibility should be considered when implementing shielding methods.

Methods for EMI Shielding in FPCs

EMI shielding methods for FPCs include copper plating, conductive silver ink printing, and EMI shielding film bonding. Each method offers unique advantages and considerations:

- Copper Plating: Traditional method suitable for multilayer flexible PCBs but may not be ideal for highly flexible applications.

- Conductive Silver Ink: Effective for high-frequency boards but comes with a higher cost and longer processing time.

- Metal Enclosures: Classic approach used in rigid PCBs but less effective for flexible circuits due to miniaturization requirements.

- EMI Shielding Film: Increasingly popular for flexible PCBs, offering cost-effective solutions with superior shielding performance for high-frequency signals.

Applications of EMI Shielding Film in Flexible and Rigid-Flex PCB Design

EMI shielding films are commonly integrated into flexible circuit applications to manage electromagnetic interference. They are essential for electronic devices sensitive to EMI, as uncontrolled interference can impact device performance. Some common applications of EMI shielding films include:

- Mobile Phones and Smartphones: EMI shielding films play a crucial role in protecting internal electronic components from external electromagnetic interference in mobile phones and smartphones, ensuring stable device performance and wireless communication quality.

- Tablets and Laptops: Tablets and laptops use EMI shielding films to shield motherboards and electronic components from external electromagnetic interference, enhancing device reliability and performance.

- Automotive Electronic Systems: EMI shielding films are applied to automotive electronic components like ECUs and navigation systems to minimize electromagnetic interference, ensuring proper functionality of the vehicle’s electronic devices.

- Medical Devices: In sensitive medical devices such as pacemakers, EMI shielding films protect internal circuits from electromagnetic interference, maintaining stable operation and accurate data.

- Industrial Control Systems: Industrial devices like PLCs rely on EMI shielding films to safeguard internal circuits from external electromagnetic interference, ensuring equipment stability and uninterrupted processes.

- Cut the EMI film to the required size.

- Remove the protective layer from the film’s bottom.

- Align and place the EMI film accurately on the flexible circuit board.

- Apply heat and pressure to bond the layers together.

EMI Shielding Films in Various Electronic Devices

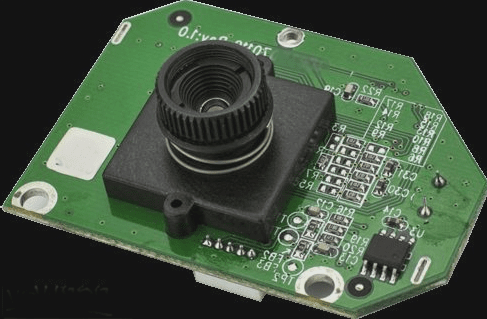

If you are involved in PCB and assembly manufacturing, you may have noticed black EMI shielding films on flexible and flex-rigid printed circuit boards—these films are crucial for protection.

WellCircuits’ EMI Shielding Films

Explore the two EMI shielding film options available at WellCircuits on the pricing page, highlighted in the red boxes in the image below:

Discover the product structure of HCF-6000G, one of the commonly used EMI shielding films, in the diagram below:

Guide to Applying EMI Shielding Film

During bonding, the conductive adhesive ensures a strong connection between the metal deposition layer and the copper circuit on the PCB, establishing an effective electrical ground connection.

If you have inquiries about PCBs or PCBA, feel free to reach out to us at info@wellcircuits.com.