PCB Surface Treatment Methods

When it comes to PCB boards, surface treatment is crucial for ensuring proper functionality and durability. There are various surface treatment processes available, each serving different purposes and meeting specific requirements. Some common surface treatment methods include:

- Oxidation Resistance: Protects the PCB from oxidation and corrosion.

- Tin Spraying: Provides a cost-effective and environmentally friendly surface coating.

- Lead-Free Tin Spraying: Similar to tin spraying but without the use of lead.

- ENIG (Electroless Nickel Immersion Gold): Deposits a layer of nickel and gold for improved solderability.

- Hard Gold Plating: Offers wear-resistant properties for high-performance applications.

- OSP (Organic Solderability Preservatives): Protects the copper surface from oxidation before soldering.

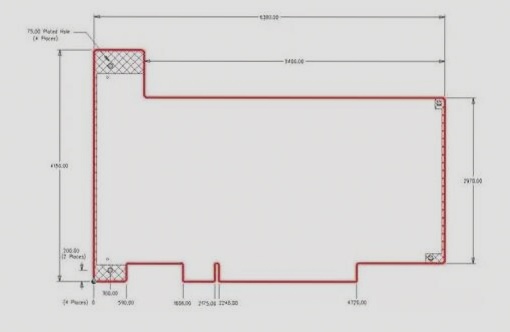

Tin Spray Panels

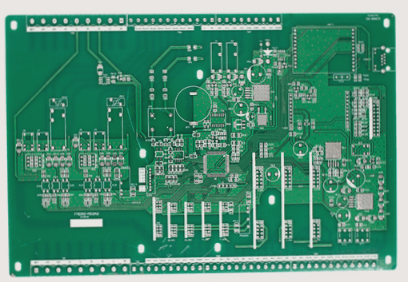

Tin spray panels are commonly used in multi-layer high-precision PCB templates. These panels play a critical role in various industries such as communication, computer technology, medical equipment, and aerospace.

One essential component of PCBs is the gold finger, which facilitates the connection between memory modules and slots. Gold fingers are crucial for transmitting signals effectively, and they are typically coated with gold or ENIG for optimal performance.

Differences Between Plating Gold and ENIG Processes

While both plating gold and ENIG offer advantages in PCB surface treatment, there are key differences between the two processes:

- Chemical Deposition: ENIG utilizes chemical deposition to create a thick layer of nickel and gold, while plating gold relies on electrolysis.

- Weldability: ENIG is known for its superior weldability compared to plating gold, making it easier to work with during PCB assembly.

- Crystal Structure: ENIG produces a denser crystal structure that is less prone to oxidation, providing better long-term reliability.

- Signal Transmission: ENIG boards maintain signal integrity without interference from the surface layer, ensuring optimal performance.

Advantages of ENIG Boards

ENIG boards offer several benefits over plating gold boards, including:

- Enhanced solderability and flatness

- Improved resistance to gold wire short circuits

- Stronger bonding between layers for better reliability

- Longer service life and superior flatness

As technology advances and PCB processing requirements become more demanding, ENIG has emerged as a preferred surface treatment method for high-quality circuit boards.