Types of PCB Surface Finishes

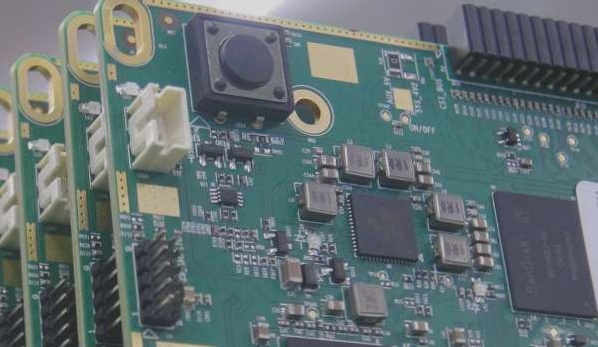

A printed circuit board (PCB) acts as a crucial support and junction for electronic components within devices. The PCB surface finish is vital for protecting the board from external damage and ensuring smooth electrical conductivity.

Importance of PCB Surface Finish

- Prevents damage, oxidation, and corrosion

- Enhances durability and reliability

- Protects internal components from deterioration

Varied Options for Different Needs

There are various types of PCB surface finishes available, catering to different requirements based on factors such as budget, environmental conditions, reliability, and reworkability.

Common Types of PCB Surface Finishes

-

Hot Air Solder Leveling (HASL)

Pros:

Cons:

-

Lead-free HASL

Pros:

Cons:

-

Immersion Tin (ISn)

Pros:

Cons:

-

Immersion Silver (IAg)

Pros:

Cons:

-

Electroless Nickel Immersion Gold (ENIG)

Pros:

Cons:

Exploring these different types of PCB surface finishes can help you make an informed decision based on your specific needs. Remember, choosing the right surface finish is crucial for the performance and longevity of your PCB.

If you need assistance in selecting the most suitable and cost-effective surface finish for your PCB, consulting a professional PCB fabricator is recommended.

Discover more about PCB fabrication: PCB Fabrication