Clean Hole Treatment

The PCBA black holeization solution contains graphite and carbon black, which are negatively charged. These components repel the negative charge on the resin surface of the hole wall after drilling, preventing electrostatic adsorption. To enhance the adhesion of graphite and carbon black, it is essential to adjust the positive charge of the regulator to neutralize the negative charge on the resin surface or give the pore wall resin a positive charge.

Water Cleaning

It is crucial to remove excess residual liquid from both the hole and the surface to ensure a clean PCB assembly process.

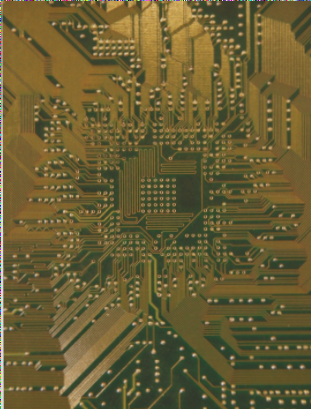

PCBA Black Hole Treatment

By utilizing physical adsorption, a uniform and fine conductive layer of graphite carbon black is applied to the surface of the hole wall substrate.

Additional Tips

- Water Cleaning: Ensure thorough removal of excess residual liquid.

- Drying: Eliminate moisture in the adsorption layer through high-temperature and low-temperature treatments to improve adhesion.

- Micro-Etching Treatment: Utilize an alkali metal boron salt solution to create microporous channels for effective black holeization.

- Inspection: Verify the completeness and evenness of the coating using an inspection mirror or stereo microscope.

- Electroplated Copper: Employ impulse current in the tank to ensure full coverage of conductive plating.

Important Considerations

- The black hole solution tank should have a circulating stirring device for optimal results.

- Use appropriate drying methods based on the material’s heat resistance.

- Regularly test the PCBA black hole liquid for solidity and pH value to maintain stability.