Understanding FPC Cables: Composition and Functionality

- FPC cables, as a type of FPC, share a similar composition to traditional FPC.

- Typically elongated, FPC cables feature pluggable pins on both ends for direct connections to connectors or soldering onto products.

- The central section of FPC cables usually contains a circuit, with the base material commonly being rolled copper for flexibility and resilience.

- Surface treatment of FPC cables often involves gold, with some instances of anti-oxidation treatments.

- Immersion gold technology is widely preferred over anti-oxidation processes due to its higher temperature resistance and environmental durability.

- FPC cables can withstand bending, twisting, and movement without damage, making them ideal for interconnection systems with continuous motion.

- FFC cables are a cost-effective alternative to FPC cables, favored by many companies for design purposes.

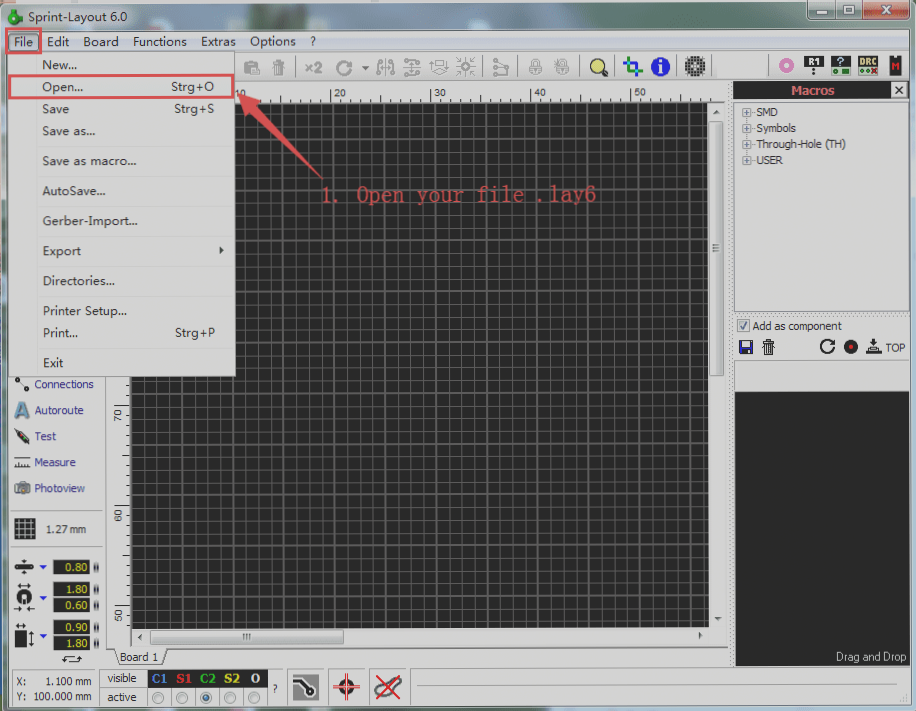

When discussing FPC cables, it’s crucial to understand their versatility and functionality. FPC cables, a subset of FPC, are known for their ability to bend and flex to a certain degree. They come in various specifications, including different pitch flexible cables ranging from 0.5mm to 2.54mm.

These cables are designed to endure millions of bending cycles, making them reliable for systems with continuous movement. Unlike rigid PCBs, which often fail under stress after hundreds of cycles, FPC cables maintain their integrity. Jenny, a product manager at EECX, highlighted the importance of electrical signals and the suitability of flat cables for smaller products.

Reinforcement materials like FR4, PI, and steel sheet are available for FPC flexible circuit boards to enhance high-temperature resistance during soldering or adhesive processes.