Optimizing PCB Design for IoT Applications: A Comprehensive Guide for Electronics Manufacturers

The Internet of Things (IoT) market continues its explosive growth, with global spending projected to reach $1.1 trillion by 2023 according to IDC research. As a leading PCB manufacturer in China specializing in IoT-ready circuit boards, we understand the unique challenges of creating reliable, high-performance designs for connected devices.

Key Considerations for IoT PCB Design

1. Analog & Digital Signal Processing in IoT Devices

Modern IoT PCB designs require careful integration of both analog and digital components:

- Analog-to-digital converters (ADC) bridge the physical and digital worlds

- High-resolution ADCs enable precise environmental sensing

- Digital signal processors (DSP) manage complex IoT algorithms

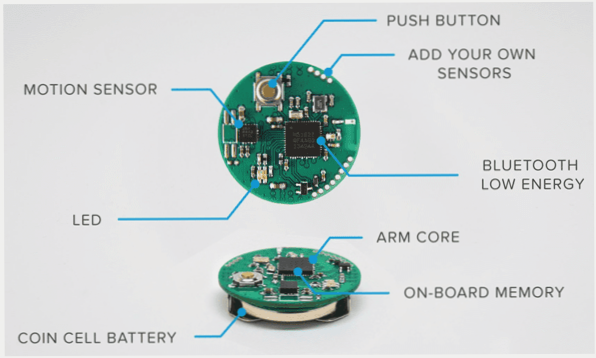

2. Micro-Electro-Mechanical Systems (MEMS) Integration

When selecting MEMS components for IoT applications, consider:

- Motion sensors for wearables and industrial monitoring

- Environmental sensors for smart home devices

- Proper PCB mounting techniques for vibration-sensitive components

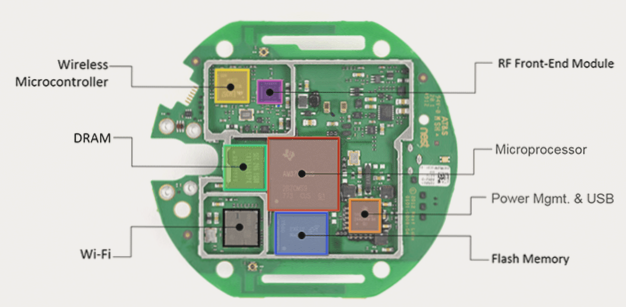

3. RF Connectivity Solutions for IoT Products

Choosing the right wireless communication module depends on:

- Range requirements (Bluetooth vs. WiFi vs. LoRa)

- Power consumption constraints

- Antenna placement and PCB layout considerations

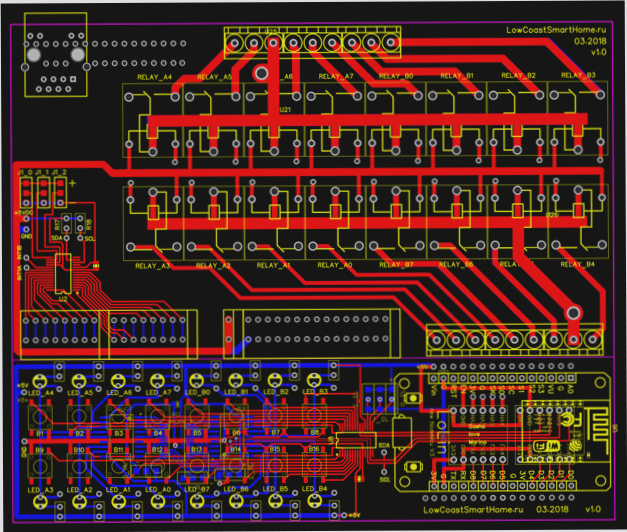

Designing for IoT Form Factors

Successful IoT product development requires balancing functionality with physical constraints:

“The best IoT PCB manufacturers in China understand that wearables demand ultra-compact designs without compromising performance.”

Key Form Factor Considerations:

- Flexible PCB options for curved surfaces

- Component placement for optimal thermal management

- Mechanical stress analysis for durable designs

Component Selection for IoT Applications

When designing PCBs for IoT devices, pay special attention to:

Power Management Components

- Low-power microcontrollers

- Efficient voltage regulators

- Battery charging circuits

Sensing Technologies

- Environmental sensors (temperature, humidity)

- Biometric sensors for healthcare devices

- Advanced touch interfaces

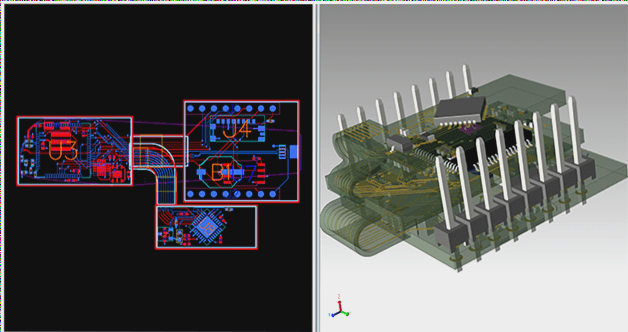

Design Verification for IoT PCBs

Our PCB design validation process includes:

Signal Integrity Analysis

- Pre-layout simulation for RF circuits

- Post-layout verification of high-speed signals

- EMI/EMC compliance testing

Power Integrity Verification

- Voltage drop analysis

- Current density simulations

- Thermal performance modeling

Memory Optimization for IoT Devices

When designing memory interfaces for IoT applications:

- Select appropriate flash memory for firmware storage

- Optimize DRAM interfaces for data processing

- Implement error correction for reliable operation

Conclusion: Partnering with an Experienced IoT PCB Manufacturer

Creating successful IoT device PCBs requires expertise in:

- Mixed-signal design techniques

- Miniaturization strategies

- Reliability engineering

As a leading PCB supplier for IoT applications, we help global clients navigate these complex requirements to deliver market-ready connected devices.