Global Copper Clad Laminate Market: Trends, Costs, and Strategic Insights for International Buyers

Understanding the Current Slowdown in Copper Clad Laminate Market Growth

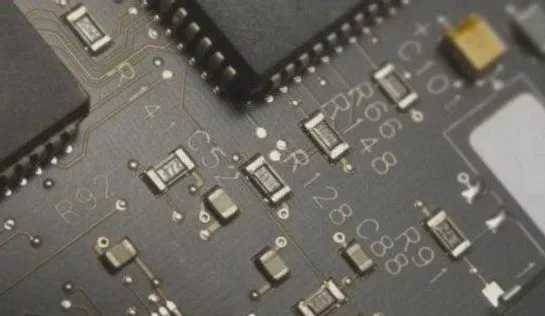

The global copper clad laminate (CCL) market is showing signs of moderated growth, presenting both challenges and opportunities for international PCB manufacturers and buyers. As the foundational material for printed circuit boards, CCL represents 50-70% of total PCB raw material costs, depending on layer complexity.

Key Manufacturing Process Explained

CCL production involves:

- Base material enhancement (paper, glass fiber, etc.)

- Resin impregnation (epoxy, phenolic, or polyimide)

- Copper foil lamination (single or double-sided)

- Hot-pressing to create final substrate

“The Chinese CCL industry bucked global trends with significant expansion post-2002, becoming the dominant player in PCB material manufacturing through strategic facility investments.”

Material Cost Breakdown: What International Buyers Should Know

Understanding CCL cost composition is crucial for global procurement specialists looking to optimize their supply chain:

FR-4 Substrates: The Industry Standard

As the most widely used CCL type, FR-4 substrates (including G-10 and FR-5 variants) dominate computer component manufacturing, particularly for:

- Motherboards

- Hard disk drives

- High-frequency PCB applications

Detailed Cost Analysis

For a standard TG4mil core board:

| Cost Component | Percentage |

|---|---|

| Raw Materials | 80% |

| Utilities | 8% |

| Labor | 8% |

| Depreciation | 4% |

Strategic Considerations for International Procurement

With copper price volatility significantly impacting CCL profitability (copper represents 63% of material costs), smart buyers are exploring:

- Vertical integration strategies with reliable CCL manufacturers in China

- Long-term contracts with top copper clad laminate suppliers

- Alternative substrate options for cost-sensitive applications

Why Source from Chinese CCL Manufacturers?

China’s dominance in PCB material production offers international buyers:

- Economies of scale from integrated manufacturing facilities

- Technical expertise in high-frequency CCL solutions

- Competitive pricing through complete supply chain control

Future Outlook: Navigating the Evolving CCL Market

As the industry adapts to raw material price fluctuations, successful international buyers focus on:

- Developing strategic partnerships with trusted CCL manufacturers

- Understanding material substitution options for cost control

- Monitoring emerging CCL technologies for next-gen PCB applications

For businesses seeking high-quality copper clad laminate suppliers, understanding these market dynamics is essential for making informed global procurement decisions and maintaining competitive PCB production costs.