The Important about PCB Material

Print Circuit Boards (PCBs) are the spine of modern electronics, providing functionality for countless devices ranging from smartphones to space exploration equipment. But, no longer are all PCBs created identical; the choice of base material considerably affects overall performance. The selection of PCB cloth considerably influences the overall performance, sturdiness, and sturdiness of your electronic device. If you’re designing or sourcing PCBs, know-how about PCB raw substances and the various PCB layers is important to making the right choice of PCB material for your challenge.

This guide will break down the entirety you want to know about PCB substances, along with kinds, properties, and how to make the proper choice in your PCB layout challenge.

Why PCB Material Matter

Every PCB consists of a couple of layers, such as a substrate layer, copper layers for conductivity, solder mask, and silkscreen, which are all critical in determining the overall PCB material selection. The PCB substances you select at once have an effect on the subsequent factors of your circuit board: conductivity, durability, and overall performance in high-frequency programs, particularly when using FR4 material.

- Electric Performance: materials have an effect on signal transmission speed, impedance control, and electrical management capacity, highlighting the importance of choosing low-loss material for optimal results.

- Thermal Management: High-exceptional materials used in PCB fabrication, like FR4, burn up heat correctly, ensuring reliable tool overall performance and longevity, particularly when considering the right PCB material selection.

- Durability: The right substances enhance structural integrity, critical for environments with high stress, exposure to chemical compounds, or extreme temperatures.

- Flexibility: Flex PCBs, for example, require specialised materials to allow bending and folding without compromising conductivity.

Types of PCB Material

PCB substances are usually categorized based on their substrate, which forms the middle or base onto which all other components are brought, reflecting how the material is chosen for specific applications. Right here’s an outline of the most widely used alternatives among the different types of PCB materials available.

1. FR-4 (Fiberglass Epoxy)

FR-4 is the enterprise-preferred fabric for plenty of PCBs due to its combination of materials that enhance performance. It’s a product of woven fiberglass material infused with epoxy resin and then laminated with copper, forming a robust layer board that meets the pcb needs. Its reputation stems from its stability of fee, performance, and durability, mainly in double-sided circuit board materials, which are among the most popular PCB material types.

Key Properties: FR4 is one of the most commonly used board materials in PCB design, particularly among the standard PCB materials available, but other materials may offer better performance in specific applications.

- High dielectric strength is a critical property for materials used in rigid PCBs.

- Affordable and widely available materials may not always be the best choice of PCB material, as performance and reliability should also be considered.

- Temperature resistance suitable for most consumer electronics is an important consideration in PCB fabrication, particularly when selecting material types for high frequency applications that require materials with specific properties.

Applications: Vias are essential for creating connections between different layers in multi-layer printed circuit board materials, especially in rf circuits.

FR-4 is commonly used in general-purpose applications for various types of PCBs. PCB assembly Its versatility makes it suitable for a wide range of applications and types of PCBs. PCB manufacturing, such as in home appliances, smartphones, and printed wiring boards.

2. Polyimide

Polyimide material is frequently used in both flexible circuits and traditional PCB designs due to its versatility and performance. flex PCB materials Rigid-flex designs are an innovative approach in modern PCB fabrication, allowing for a variety of PCB materials to be used in a single circuit design. Its excellent thermal stability and flexibility make it a favorite in high-performance and high-density applications, often utilizing FR4 material.

Key Properties:

- High resistance to thermal degradation is a key characteristic of many different PCB materials.

- Flexible and strong, perfect for bending and folding, these materials enhance the durability of the PCB surface, especially when considering different materials for various applications.

- Maintains performance in high-temperature environments, particularly with the use of suitable PCB substrates.

Applications:

Polyimide is often found in aerospace, automotive, and wearable electronics where durability and flexibility are critical.

3. PTFE (Teflon)

PTFE, also known as Teflon, is a high-frequency laminate material for advanced and specialized applications. It is valued for its low electrical loss and superior dielectric properties, making it an excellent choice for high-frequency applications.

Key Properties:

- Low dielectric constant ensures smooth, high-speed signal transmission

- Temperature resistance up to 260 degrees Celsius is critical for high-frequency applications.

- Excellent chemical resistance is a key feature of many insulating materials used in PCB manufacturing.

Applications:

PTFE is ideal for RF (Radio Frequency) and microwave applications, such as antennas, radars, and satellite systems, due to its excellent performance at high frequencies and low dielectric constant of this material.

4. Metal-Based Materials

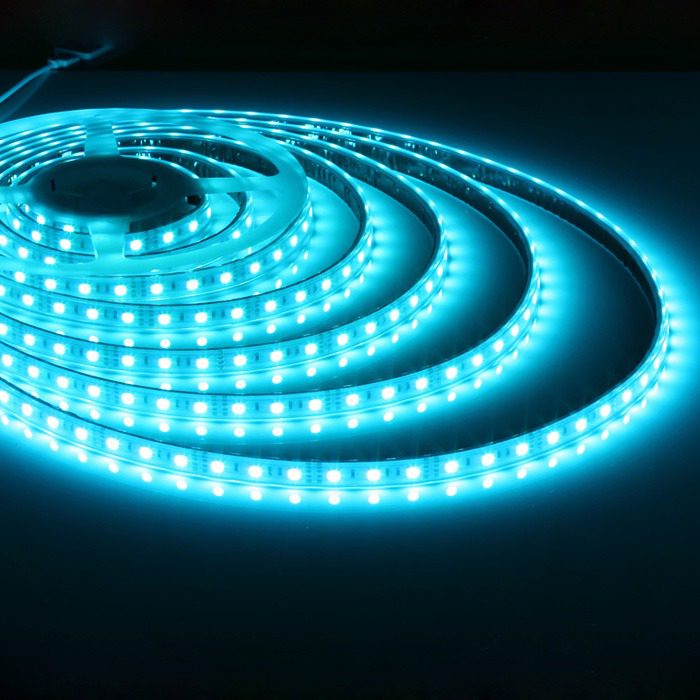

Aluminum-based or copper-based PCBs introduce metal substrates to enhance heat dissipation. They are widely used in power electronics where heat management is crucial, especially when considering the thermal properties of different PCB materials in relation to the copper layer of a PCB.

Key Properties:

- Superior thermal conductivity

- High mechanical strength and durability are achieved through the selection of appropriate conductive materials in PCB design, as these materials affect overall performance.

- Ideal for LED and power circuit boards, common PCB designs often utilize high-quality base materials.

Applications:

These materials are ideal for automotive lighting, LED displays, and power converters, particularly in high-frequency applications, where a variety of PCB materials can enhance performance.

5. Ceramic Substrates

Ceramics offer unparalleled thermal and electrical properties, making them suitable for extreme conditions and critical applications.

Key Properties:

- Outstanding heat resistance

- Low thermal expansion, reducing stress on components, is a vital characteristic of materials used in PCB assembly, especially in flexible circuits, where insulating material is crucial.

- Excellent electrical insulation

Applications:

Ceramic PCBs are used in high-frequency communications, military equipment, and medical devices like MRI systems.

Properties to Consider When Choosing PCB Material

With so many PCB materials With various PCB raw materials available, how do you decide which material is chosen as best for your project? Below are some key properties and considerations for PCB fabrication to guide your decision-making process.

1. Dielectric Constant (Dk)

The dielectric constant measures how well a material used stores electrical energy, while the loss tangent indicates energy dissipation in that material, crucial factors in evaluating PCB materials used. A lower Dk value is preferred for high-frequency signal transmission to ensure minimal signal loss, especially in high frequency applications.

2. Thermal Conductivity

For applications involving high power or heat, such as LED lighting, choosing materials with high thermal conductivity helps maintain system stability, especially when considering different types of PCB materials.

3. Flexibility

If your design involves bending or folding the PCB, opt for flexible PCB materials that enhance durability. flex PCB materials Materials used in PCB fabrication, such as Polyimide and other dk materials, provide excellent thermal stability, which is essential for the performance of the copper layer of a PCB. These materials offer the necessary mechanical flexibility while maintaining signal integrity in PCB design, making them a popular choice among various PCB materials used.

4. CTE (Coefficient of Thermal Expansion)

CTE measures how much the material expands when exposed to heat, which is an important factor when selecting materials for different types of PCBs. Materials with low CTE values are better suited for environments with fluctuating temperatures, making them an ideal choice for PCB substrates.

5. Cost

Budget constraints are a reality for many businesses, especially when selecting a variety of PCB materials that fit their needs. While FR-4 is cost-effective, investing in high-performance materials like PTFE or ceramic may be worthwhile for specialized applications, as these materials are used in high-frequency environments.

6. Signal Integrity

Applications involving high-speed or high-frequency signals require PCB raw materials with excellent electrical properties, such as PTFE and FR4.

Benefits of Choosing the Right PCB Material

Selecting the right PCB material ensures your device operates efficiently and reliably. Some of the key benefits include the ability to optimize the choice of PCB material for specific applications and environments.

- Improved Product Reliability is achieved through the use of high-quality circuit board materials.Minimize risks of overheating, signal distortion, and structural failure by carefully considering the surface of the PCB during your design process.

- Enhanced Signal Performance: Ensure accurate and uninterrupted data transmission in communication systems.

- Cost Efficiency is enhanced when considering the long-term benefits of choosing the right materials for PCB fabrication.Avoid unnecessary costs stemming from poor performance or frequent repairs by choosing the right layer board, as the choice of PCB material can significantly impact durability.

- Sustainability: Opt for environmentally friendly materials when possible to align with global sustainability goals.

Flex PCB Materials for Specialized Applications

Flex PCBs have become increasingly popular for compact, lightweight, and dynamic designs, often utilizing low-loss material for better performance, which is an important choice of PCB material in modern circuit design. They excel in environments where traditional rigid boards would fail, showcasing the advantages of flexible PCB substrates.

Why Choose Flex PCB Materials? The advantages of flexible circuits make them ideal for innovative designs and applications.

Flex PCB materials offer benefits such as high dielectric strength and low loss tangent, making them suitable for various applications, particularly when choosing a PCB material for high-frequency designs.

- Space-saving designs for compact devices are crucial in modern PCB assembly, especially when using advanced PCB laminates to optimize space and enhance the performance of the copper layer of a PCB.

- Durability under repetitive movements is essential for electronic components in PCB assembly, especially when utilizing high-quality conductive materials.

- Customizable shapes and sizes for innovative applications

Flex PCBs are used in everything from wearable technology to robotic systems, making them an essential component in modern engineering, particularly with different materials to meet specific needs.

How We Can Help

Navigating the world of PCB materials may seem daunting, but understanding the standard material types can simplify the process. PCB materials can feel overwhelming, but it doesn’t have to be; understanding the different PCB materials can simplify the process. With years of experience in PCB manufacturing, our team can help you identify the perfect substrate material to bring your project to life, ensuring the right choice among PCB material types. Whether you’re creating flex PCBs for wearable devices or high-frequency boards for advanced telecommunications, we’ve got you covered with a variety of material types.

Contact us for expert advice on selecting the right interconnect solutions and base material for your project. Contact us today to request a quote and get started on your next printed circuit board material project that requires materials tailored to your specifications.