The Process of PCBA: Manual vs. Automated Assembly

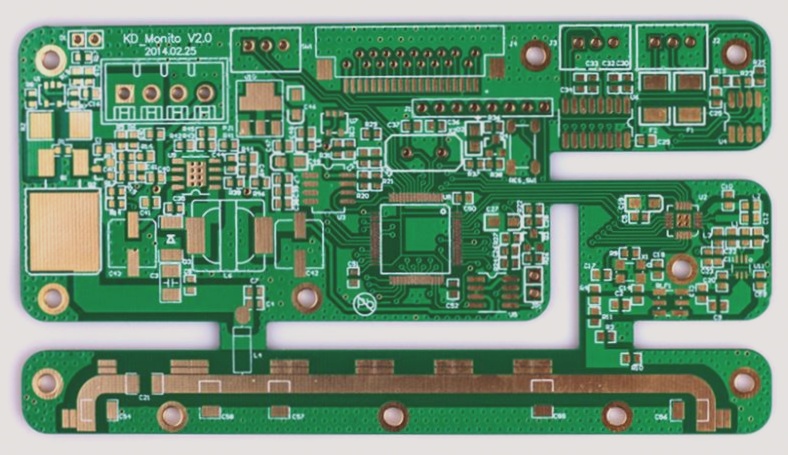

- Manual Assembly:

- Challenges in Manual Assembly:

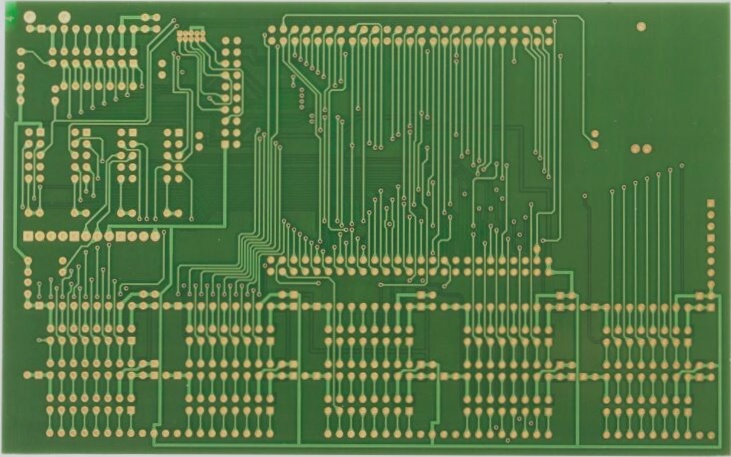

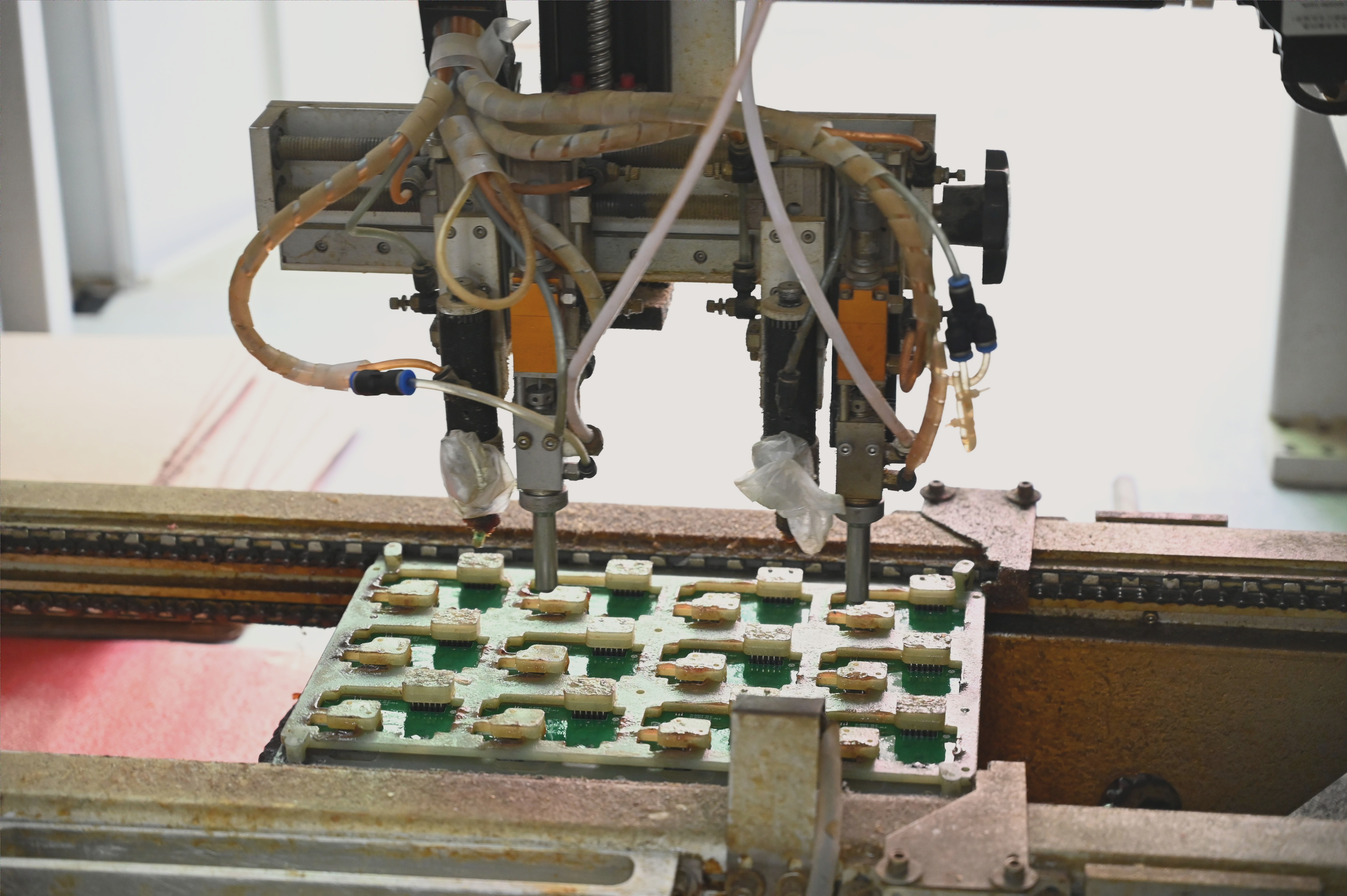

- Automated Assembly:

In manual assembly, operators place odd-form components directly onto the circuit board. The soldering process is automated, but operators handle component placement. Special attention is required to avoid ESD damage and ensure components are placed correctly.

Operators must be cautious of ESD damage and thermal issues during manual soldering of odd-form components. Pb-free soldering adds complexity, requiring careful temperature control to prevent damage.

Value of Manual Assembly

Boards processed through manual assembly hold higher value, making damage during this process costly. Careful consideration of manual assembly steps is crucial during product design and process development.

Automated assembly of odd-form components uses specialized equipment and tooling to enhance efficiency. Speed is a key factor in the performance of these machines, as odd-form component placement can slow down production.

Advantages of Automated Assembly

Automated assembly offers increased efficiency and versatility in handling odd-form components, minimizing production bottlenecks.

Disadvantages of Automation

Despite its benefits, automated assembly may have limitations and challenges in handling certain odd-form components.