Comprehensive Guide to PCB Testing Methods for Quality Assurance in Electronics Manufacturing

Printed Circuit Boards (PCBs) serve as the foundation for electronic components and their electrical interconnections. As a leading PCB manufacturer in China, WellCircuits specializes in producing high-reliability boards for medical devices, consumer electronics, and industrial equipment. With growing demand for complex PCB designs, rigorous PCB & PCBA testing methods have become essential for ensuring product reliability.

Why PCB Testing is Critical for Electronics Manufacturers

Implementing comprehensive PCB quality control processes offers three key benefits for global buyers:

- Cost reduction through early defect detection

- Time savings by preventing downstream production issues

- Safety optimization for mission-critical applications

“The cost of fixing PCB defects increases exponentially at later production stages. Our automated PCB testing solutions catch 99.7% of defects before final assembly.” – WellCircuits Quality Assurance Team

Common PCB & PCBA Defects Requiring Testing

PCB-Specific Defects

- Open circuits and insufficient connections

- Short circuits and solder bridges

- Missing or misaligned components

- Defective electrical/non-electrical components

PCBA Assembly Defects

- Soldering issues: voids, bridges, insufficient/excess solder

- Component problems: missing, misaligned, or incorrect parts

- BGA/CSP defects: hidden solder ball issues

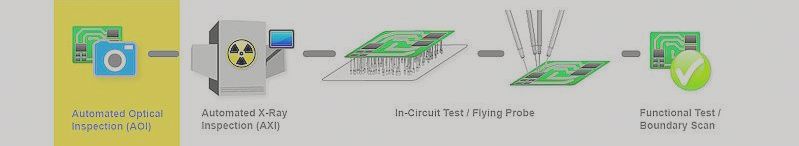

Advanced PCB Testing Techniques for Global Manufacturers

1. Manual Visual Inspection (MVI)

This traditional PCB quality check method uses magnification tools for basic defect detection. While cost-effective for simple boards, MVI has limitations for high-density interconnect (HDI) PCBs and is prone to human error.

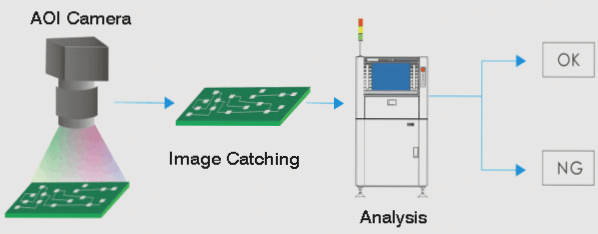

2. Automated Optical Inspection (AOI)

Our China-based PCB factory utilizes high-resolution AOI systems that compare board images against design files. This automated PCB inspection method detects 95% of surface defects before reflow, reducing rework costs by 10x compared to final-stage detection.

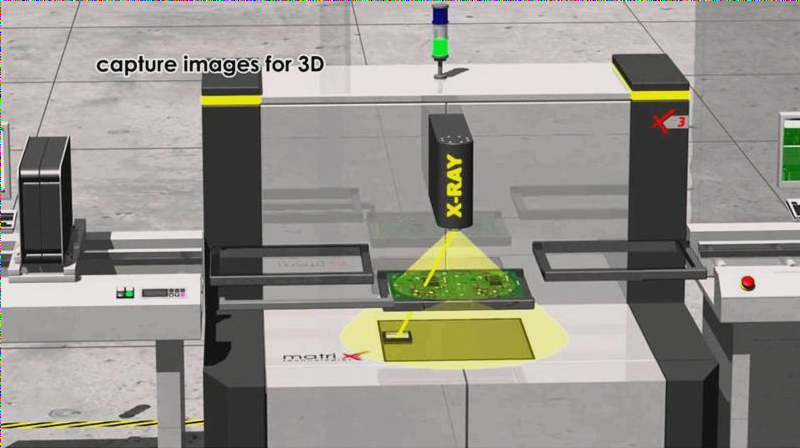

3. Automated X-Ray Inspection (AXI)

For BGA package inspection and hidden solder joints, AXI provides unparalleled visibility. This advanced PCB testing technology is essential for:

- Ultra-fine pitch components

- Multilayer board verification

- Double-sided SMT assemblies

4. Bed of Nails Testing

This fixture-based method checks electrical parameters through direct contact with test points. While excellent for production runs, our engineers recommend flying probe testing for PCB prototypes due to lower fixture costs.

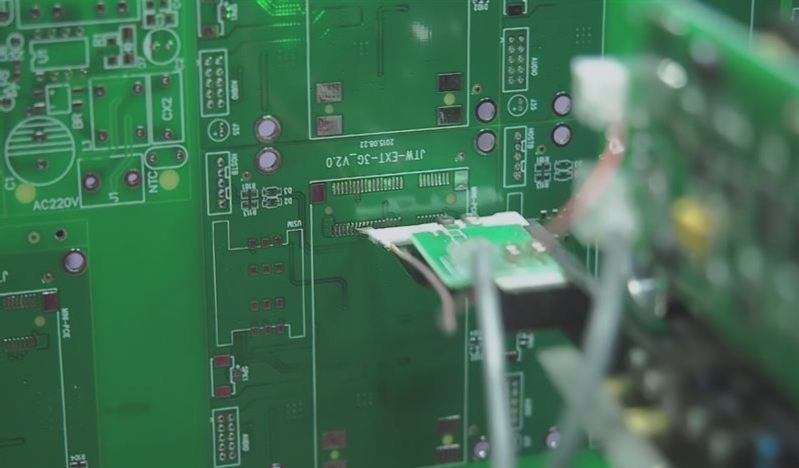

5. Flying Probe Testing

As a reliable PCB testing solution for small batches, this contactless method excels at:

- High-density board verification

- Analog component testing

- Short/open circuit detection

6. Functional Testing

The final PCBA validation process simulates real-world operating conditions to ensure:

- Proper power-up sequences

- Correct signal processing

- Full system functionality

Choosing the Right PCB Testing Strategy

When selecting PCB testing services in China, consider these factors:

- Board complexity and component density

- Production volume and prototype requirements

- Industry-specific quality standards

- Budget constraints versus risk tolerance

WellCircuits offers custom PCB testing solutions combining multiple techniques for comprehensive quality assurance. Our ISO-certified facility features:

- Full-spectrum testing capabilities

- Experienced engineering support

- Fast turnaround for international clients

For high-quality PCB manufacturing with rigorous testing, contact our team to discuss your project requirements and receive a competitive quote within 24 hours.