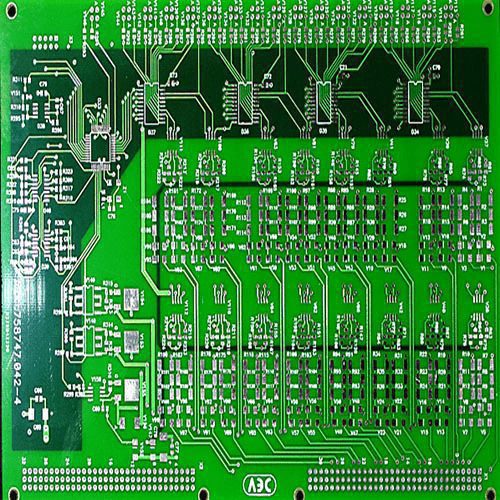

Common Causes of Blackening in Electroplated Gold Layer in PCB Processing

1. Thickness Control of Electroplated Nickel Layer

The blackening issue in the electroplated gold layer is often caused by inadequate thickness of the electroplated nickel layer. A nickel layer thickness of around 5UM is recommended to prevent surface problems like whitening and blackening. Regular checks by plant engineering technicians are necessary.

2. Potion Condition of Electroplating Nickel Cylinder

Poor maintenance and lack of carbon treatment in the nickel tank can result in flake crystals, increased hardness, and brittleness of the coating, leading to blackening. Regular maintenance and timely carbon treatment are crucial to avoid this problem.

3. Control of Gold Cylinder

Proper potion filtration and replenishment are essential to maintain the pollution degree and stability of the gold tank. Controlled addition of gold tank supplements, pH regulation of the potion, and monitoring of impurities in the solution are key factors in preserving the potion status of the gold cylinder.

Conclusion: Addressing the thickness control of the electroplated nickel layer, maintaining the potion condition of the electroplating nickel cylinder, and effectively controlling the gold cylinder are crucial in minimizing blackening issues in PCB processing.