SMT Assembly Challenges and Solutions

SMT assemblies are becoming increasingly complex, presenting challenges for PCB manufacturers aiming for 100% output. The shrinking size of SMT components complicates PCB placement, leading to various difficulties that need to be addressed.

Challenges Faced by PCB Manufacturers:

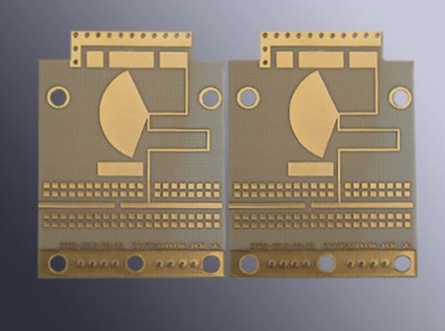

- Poor Solder Paste Release: Aspect ratio and surface area ratio of the template influence solder paste release, with aspect ratios below 1.5 and a minimum surface area ratio of 0.66 considered unacceptable.

- Bridging During Printing: Copper weight and surface finish impact the seal between the PCB and template, potentially causing solder paste extrusion and bridging issues.

- Insufficient Solder Volume in SMT Reflow: Detection of insufficient solder volume usually occurs during optical inspections, necessitating adjustments to accommodate differences in component sizes.

- SMT Reflow Bridging: Solder paste squeezing out between PCBs during reflow can lead to bridging issues, particularly with gull-wing packages due to uneven heating of exposed leads.

Solutions to Overcome These Challenges:

- Optimizing template aperture width for heavy copper weight and uneven surface finish to prevent solder paste extrusion.

- Increasing solder volume and applying extra paste to address insufficient solder volume during SMT reflow.

- Focusing on reducing solder volume on gull-wing feet to prevent reflow bridging and ensure uniform heating.

While specific SMT defects may vary, issues like solder paste release, printing bridging, and reflow bridging are common. Addressing these challenges is crucial to maintain operational reliability in SMT assemblies.