Castellated PCB Guide: Types, Specifications, and Applications for Export-Oriented Businesses

What Are Castellated Holes on a PCB?

With the rapid advancement of high-density electronics, manufacturers increasingly demand miniaturized PCB solutions with enhanced functionality. Traditional through-hole soldering methods often result in cold solder joints due to excessive hole size, compromising electrical connections between motherboards and daughterboards. This has driven global demand for plated half-hole PCB technology – a superior solution for modern board-to-board connections in compact devices.

Castellated Holes (Plated Half-Hole PCB) Explained

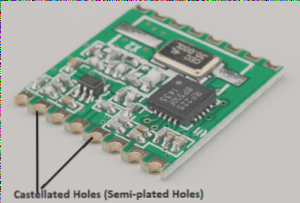

Castellated holes, also called castellations, are semi-plated indentations along PCB edges that enable secure surface-mount assembly of multiple boards. These precision-engineered features:

- Facilitate perfect alignment during PCB module stacking

- Eliminate the need for bulky multi-pin connectors

- Enable direct board-to-board soldering with minimal profile

“Castellated hole technology revolutionizes PCB assembly by combining the reliability of through-hole connections with the space efficiency of SMT components.” – PCB Manufacturing Expert

PCB Manufacturing Process for Castellated Holes

Leading PCB manufacturers in China follow this rigorous process for plated half-hole production:

- Precision drilling of via holes

- Electrolytic copper panel plating

- Image transfer and pattern plating

- Etching and solder mask application

- Surface finishing (ENIG recommended)

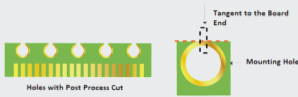

- Precision routing to create half-hole profiles

Key Benefits of Castellated Holes for Export Businesses

For international electronics manufacturers, castellated PCBs offer:

- Space-saving solutions for compact device designs

- Simplified assembly of modular PCB components

- Cost-effective alternative to complex connector systems

- Reliable wireless module integration (Wi-Fi/Bluetooth)

Design Considerations for Castellated Holes

When specifying castellated hole PCB designs for export products:

- Minimum diameter: 0.6mm for standard PCBs

- Spacing: ≥0.55mm between holes

- Surface finish: ENIG preferred for reliable soldering

- Pad design: Maximize contact area

Castellated Hole Variants for Different Applications

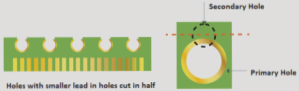

PCB engineers can choose from multiple castellation types:

- Standard half-holes: Most common for general applications

- Stepped castellations: For connector compatibility

- Microvia castellations: For ultra-high density designs

Industry Applications of Plated Half-Hole Technology

Castellated PCBs are transforming these export-focused industries:

- Telecommunications: 5G modules and base station electronics

- Automotive: Compact ECU designs

- Industrial IoT: Sensor modules and edge devices

- Consumer Electronics: Wearables and smart home devices

Choosing the Right Castellated PCB Manufacturer

When sourcing castellated hole PCBs from China, verify these capabilities:

- Advanced laser drilling equipment

- Strict quality control for plated hole integrity

- Experience with high-frequency PCB materials

- Certifications for export markets (UL, IPC, RoHS)

For export-quality castellated PCBs with competitive lead times, consult with our technical team today.