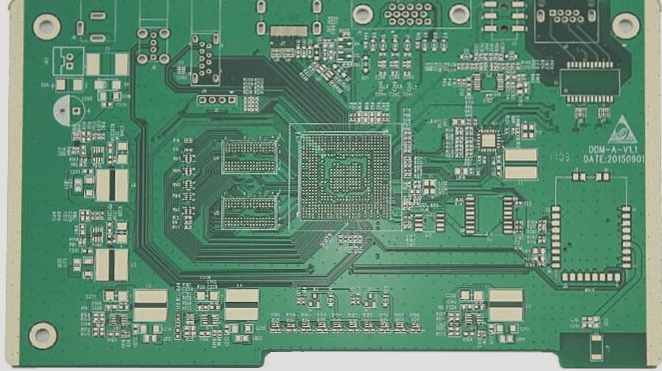

How to Secure Tiny Wires on PCBs

When working with PCBs, securing tiny wires can be a challenge. Whether you need to create a test point for viewing waveforms or extracting timing signals, it’s essential to ensure the wires remain in place. Here are some tips to help you achieve a secure connection:

- Consider using teflon-coated or magnet wire for better insulation and durability.

- When soldering, tin the wires slightly and use plenty of flux to improve adhesion.

- Inspect the soldered area carefully using a microscope to check for any issues.

- If the available soldering area is minimal, consider using specialized tools or products designed for securing wires in tight spaces.

- If traditional soldering methods are not keeping the wires in place, explore alternative options such as hot glue for additional anchoring.

Do you struggle with keeping tiny wires connected to chips on your PCBs? Explore cost-effective products that can help you press a test lead to a specific spot and hold it securely without breaking the bank.