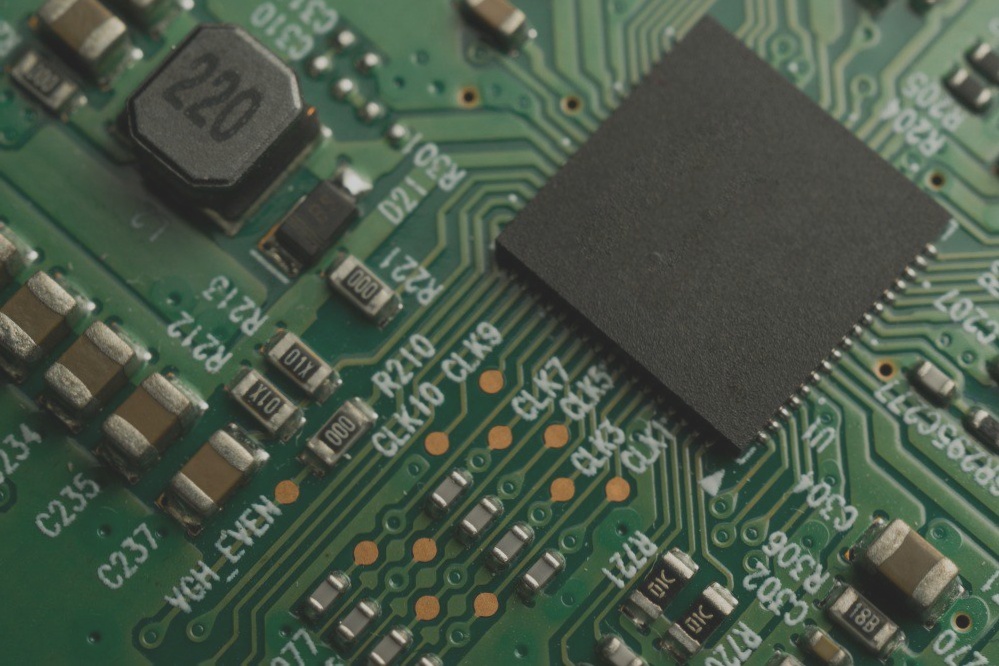

PCBA Installation Tips and Analysis

When installing the reinforced frame and PCBA, it’s crucial to pay attention to potential warpage issues. For PCBA or frames that don’t meet specifications, implementing effective “pad” measures at the twisted areas before installation is essential to prevent stress on components like high-density ICs and relay holes.

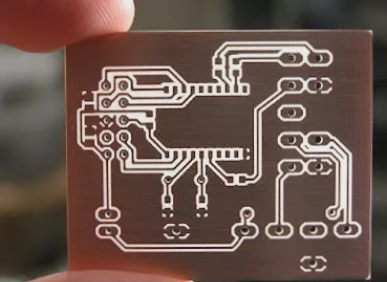

Common Issues with Ceramic Chip Capacitors

- Ceramic chip capacitors have high defect rates, often due to:

- PCBA bowing from wiring harness stress

- Excessive flatness post-welding

- Asymmetrical pad design

- Incorrect soldering parameters

- Thermal expansion differences

- Insufficient distance in PCB design

Preventing Ceramic Chip Capacitor Damage

- Optimize solder amount for proper stress distribution

- Use C-SAM and SLAM for capacitor screening

- Avoid external stress-induced cracks

- Ensure correct pick-and-place machine settings

- Watch for cracks from pick-and-place head extrusion

Solution for Defective Capacitors

To address defects, enhance screening processes using advanced techniques like C-SAM and SLAM to identify and replace faulty ceramic chip capacitors.