PCB Failure Analysis: Ensuring Quality and Reliability

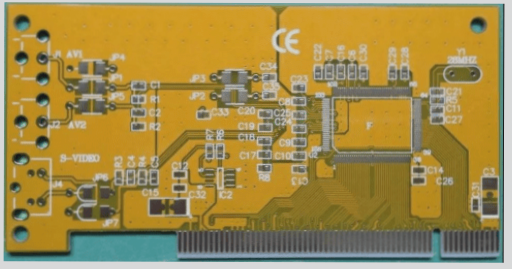

PCBs are the backbone of electronic devices, playing a crucial role in ensuring optimal performance and dependability. However, as technology advances, the development of PCBs faces new challenges and demands.

Current Trends in PCB Development

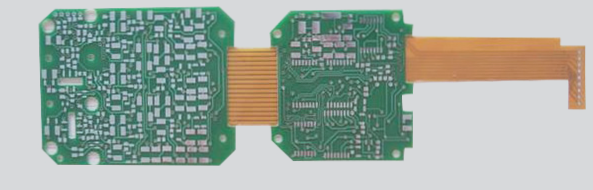

- Miniaturization of electronic products

- Shift towards lead-free and halogen-free designs

- Higher density and Tg

- Improved environmental sustainability

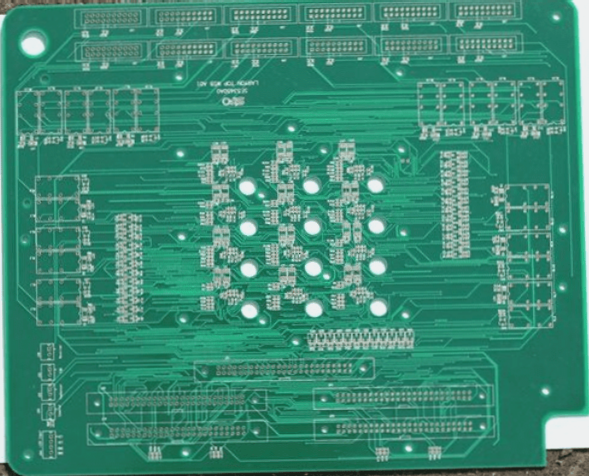

The Importance of Failure Analysis

Despite advancements, issues in PCB production and application persist, leading to quality disputes. Conducting thorough failure analysis is essential to identify root causes, formulate solutions, and ensure accountability.

Basic Procedure for Failure Analysis

To pinpoint the cause of PCB failures accurately, a systematic approach is crucial. The process involves:

- Identifying failure location and mode through testing and inspection

- Analyzing failure mechanisms using physical and chemical techniques

- Conducting root cause analysis and test verification

- Compiling a detailed failure analysis report

Preventing Data Loss in Failure Analysis

It is vital to follow a structured analysis approach, avoiding sample destruction and maintaining the integrity of the failure site. Similar to a traffic accident investigation, tampering with evidence can lead to inaccurate conclusions.

If you have any inquiries regarding PCBs, feel free to reach out to us at info@wellcircuits.com.