Multilayer PCB Technology: The Backbone of Modern Electronics for Global Trade

What Are Multilayer PCBs and Why Are They Essential?

Printed Circuit Boards (PCBs) form the foundation of all electronic devices, enabling functionality through interconnected components and conductive pathways. Among PCB variants, multilayer PCBs stand out as sophisticated solutions combining multiple conductive layers separated by insulating dielectric material. As a leading PCB manufacturer in China, we specialize in producing high-performance multilayer boards that meet international standards for complex applications.

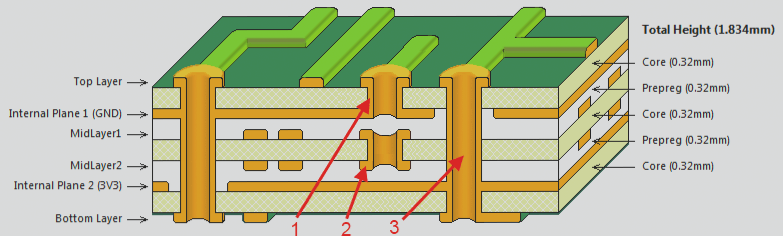

Understanding Multilayer PCB Architecture

Layer Configuration and Material Selection

Multilayer PCBs typically range from 4 to 12 layers for commercial applications, with advanced systems requiring up to 100 layers. Key considerations include:

- Even-numbered layers preferred for manufacturing efficiency

- Specialized via technologies (blind and buried vias) for space optimization

- Dedicated planes for power, ground, and signal routing

Advanced Manufacturing Process

Our multilayer PCB production follows rigorous international protocols:

“Precision lamination under high temperature and pressure ensures perfect layer bonding while eliminating air gaps – a critical factor for signal integrity in high-frequency applications.”

Material options include FR-4 epoxy, high-Tg materials, Rogers substrates, and specialized ceramics for demanding environments.

Technical Advantages for Global Export Markets

When sourcing multilayer PCBs from China, international buyers benefit from:

- Higher circuit density enabling compact designs

- Superior EMI/RFI shielding capabilities

- Enhanced signal transmission quality

- Reduced system weight and footprint

- Improved thermal management

Critical Design Considerations for Export-Quality PCBs

Signal and Power Integrity

Our engineering team addresses key challenges in high-speed PCB design:

- Controlled impedance trace routing

- Optimized copper weight and trace geometry

- Proper ground plane implementation

- EMI mitigation through strategic layer stacking

Thermal Management Solutions

We implement advanced techniques to handle thermal challenges in high-power PCB applications:

- Thermal via arrays

- Copper thickness optimization

- Strategic component placement

Global Applications of Multilayer PCB Technology

Our export-quality multilayer PCBs power critical systems worldwide:

- Telecommunications: 5G infrastructure, cell towers, fiber optic systems

- Medical Technology: MRI machines, patient monitors, diagnostic equipment

- Aerospace & Defense: Satellite systems, avionics, radar equipment

- Industrial Automation: Robotics, control systems, IoT devices

- Consumer Electronics: Smartphones, wearables, computing devices

Why Choose Our Multilayer PCB Manufacturing Services?

As a trusted PCB supplier for international trade, we offer:

- ISO-certified production facilities

- RoHS and REACH compliant materials

- Rigorous quality control and testing protocols

- Custom solutions for specialized applications

- Competitive pricing for bulk orders

- Efficient global logistics network

Navigating the Future of PCB Technology

The demand for high-density interconnect (HDI) PCBs continues to grow across industries. Our R&D team stays at the forefront of:

- Advanced materials development

- Miniaturization techniques

- High-frequency design solutions

- Sustainable manufacturing processes

For international buyers seeking reliable multilayer PCB manufacturers in China, our expertise ensures superior quality, technical excellence, and competitive advantage in global markets.