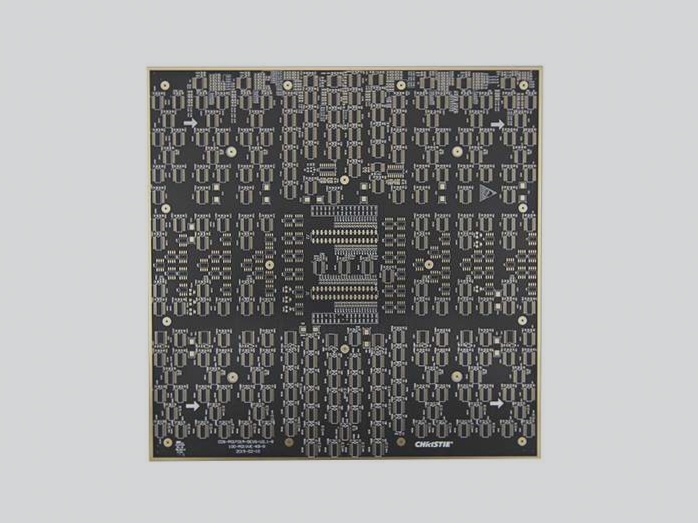

Comparison of SMT and Through-Hole Materials in PCBA Manufacturing

When it comes to PCBA manufacturing, Surface Mount Technology (SMT) components offer a range of advantages:

- Reduced solder joint defect rate

- Enhanced reliability and robust anti-vibration properties

- Improved high-frequency characteristics, reducing electromagnetic and radio frequency interference

- Lightweight: SMT components weigh only 10% of traditional DIP through-hole components, resulting in a weight reduction of 60% to 80% upon adoption

- Compact size: SMT prototype components occupy just about 10% of the volume compared to traditional DIP through-hole components, leading to a 40% to 60% reduction in product volume

- Cost-effectiveness: SMT assembly allows for automation, boosting production efficiency and saving costs ranging from 30% to 50%

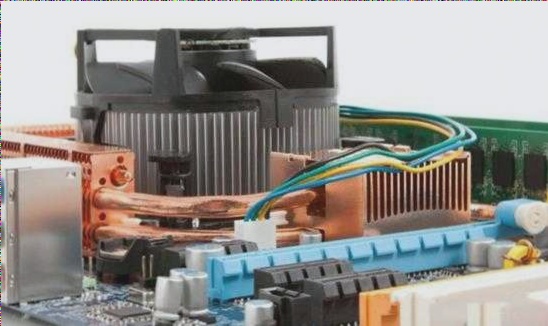

The Advantages of Plug-in Components

- In electronic products with high heat dissipation requirements, plug-in components excel over SMT chip materials due to superior heat dissipation properties, enhancing product stability and performance

- Plug-in components have a lower failure rate compared to PCBA, making inspection more convenient

- Plug-in components demonstrate exceptional stability in extreme environments with turbulence and vibration, requiring engineers to carefully evaluate and select the most suitable components for optimal PCBA packaging effects