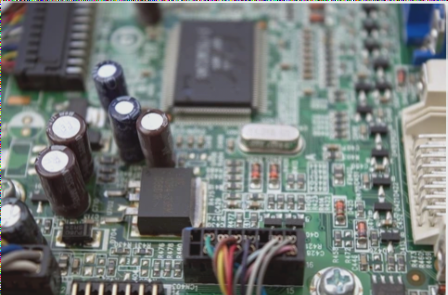

The Advantages of Multi-Layer Circuit Boards in PCB Design

Multi-layer circuit boards are essential in high-speed PCB design, offering various benefits for small-volume electronic products. Let’s delve into the key advantages:

- High Assembly Density and Compact Size: With electronic devices getting smaller, multi-layer boards meet the demand for high PCB electrical performance.

- Simplified Routing and Enhanced Signal Transmission: Multi-layer boards streamline the routing process, shorten trace lengths, and improve signal transmission speed.

- Improved Grounding for High-Frequency Circuits: Adding a ground layer reduces circuit impedance and enhances shielding effectiveness.

- Effective Heat Dissipation: Multilayer PCBs with metal core heat dissipation layers address heat dissipation needs for products with high thermal requirements.

Performance and Cost Considerations

While multi-layer boards outperform single- and double-layer boards, they come with higher production costs and processing times. However, the noise reduction benefits and advancements in technology have led to the use of PCBs with over 100 layers in specialized equipment.

Types of Multi-Layer PCBs

The most common multi-layer boards are four-layer and six-layer boards, with the latter featuring additional internal signal layers. Design flexibility, economic advantages, stable electrical performance, and reliability make multi-layer boards popular in electronics.

PCB Layout Tips

Consider the PCB size for interference resistance and cost optimization. Place special components strategically, like clock components, to avoid interference with critical signal paths. Design the layout based on circuit functions and optimize component placement for anti-interference performance.

If you require PCB manufacturing services, feel free to contact us.