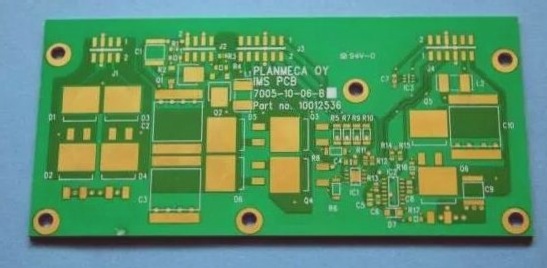

PCB Surface Treatments Overview

Printed circuit board surface treatments play a crucial role in ensuring the functionality and longevity of PCBs. Various treatments, such as anti-oxidation, tin spray, lead-free tin spray, immersion gold, and more, cater to different needs and requirements in the electronics industry. Let’s explore some key surface treatments:

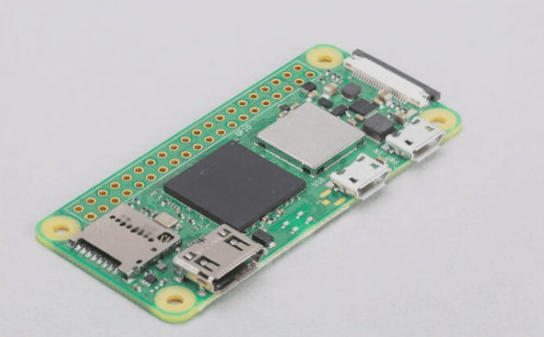

Tin Spray Boards for High-Precision PCB Models

Tin spray boards are commonly used in high-precision PCB models with multiple layers, ranging from 4 to 46 layers. These boards are favored by major communication, computer, medical equipment, and aerospace companies for their reliability and performance.

The Significance of Gold Fingers

Gold fingers are essential connectors in memory sticks, facilitating communication between different components. While gold plating offers excellent oxidation resistance and conductivity, the high cost has led to a shift towards tin plating in most memory connectors. Gold plating remains prevalent in high-performance server and workstation accessories.

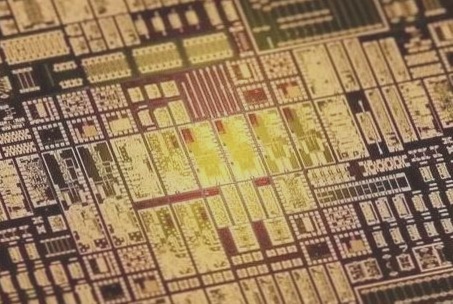

Advantages of Gold Plating in PCBs

Gold-plated boards address challenges related to IC pin density and pad flatness, especially in surface mount processes with ultra-small components. The longer standby life of gold-plated boards compared to lead-tin alloys makes them a preferred choice, despite similar costs in the sampling stage.

Benefits of Immersion Gold Boards

Immersion gold boards offer advantages over traditional gold-plated boards, including improved solderability, reduced risk of short circuits, and better spacing integrity during assembly. The crystal structure of immersion gold enhances soldering ease and customer satisfaction, making them a popular choice for many PCB applications.

Immersion Gold vs. Gold-Plated Boards

When choosing between immersion gold and electroplating gold processes, immersion gold is often preferred due to its ability to reduce the tin whisker effect, making it a common choice among manufacturers for various applications.

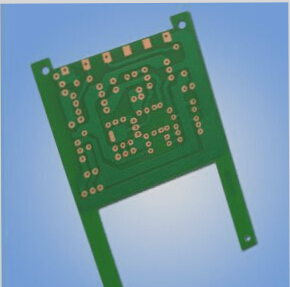

Surface Treatments for PCB Circuit Boards

- Gold plating (electroplating and immersion)

- Silver plating

- OSP (Organic Solderability Preservatives)

- Tin spraying (leaded and lead-free)

Issues with poor tin plating on PCB circuit boards are often linked to factors like solder paste quality and manufacturing technologies utilized by chip manufacturers.

Key Considerations for PCB Circuit Boards

- Presence of oil-permeable film on PAN (Panel Area Network) affecting tinning effect

- Tin leaching test for verifying tinning effectiveness

- Lubrication of PAN position for maintaining pad integrity

- Ion contamination tests for assessing pad contamination

It’s essential for PCB manufacturers to address these concerns during the production process.

Advantages and Disadvantages of Surface Treatment Methods

- Gold Plating: Offers longevity and stability against environmental changes, suitable for up to one year of storage.

- Tin Spraying and OSP Treatments: More sensitive to ambient conditions, requiring careful storage.

- Immersion Silver: Slightly different in cost and storage needs, necessitating packaging in sulfur-free paper.

Understanding the nuances of each surface treatment method is crucial for ensuring the quality and reliability of PCB circuit boards.