PCB Surface Finish Types and Their Importance in Global Manufacturing

In PCB manufacturing, surface finishes play a critical role in protecting copper traces from environmental factors like oxidation and humidity while ensuring reliable solderability for component assembly. Selecting the right PCB surface finish directly impacts product performance, longevity, and compliance with international standards.

How to Choose the Best PCB Surface Finish for Your Project

With evolving technology demanding finer pitches and thinner coatings, manufacturers must evaluate multiple surface treatment options. Below we analyze the top PCB surface finishes used by leading PCB manufacturers in China, their advantages, limitations, and ideal applications.

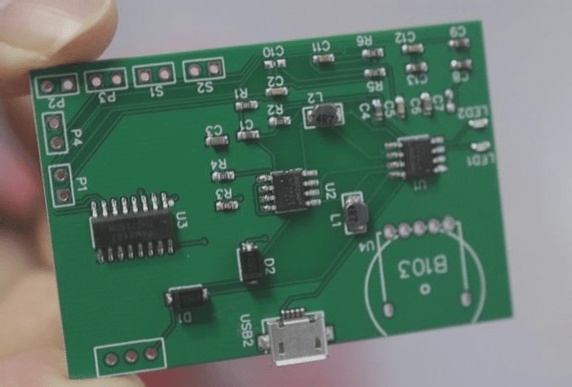

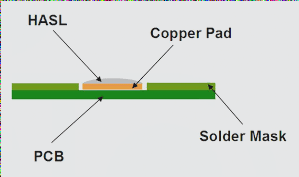

1. HASL/Lead-Free HASL: The Cost-Effective Standard

Hot Air Solder Leveling (HASL) remains the most widely used surface finish globally. This process involves:

- Dipping PCBs in molten solder (lead or lead-free)

- Removing excess solder with hot air knives

- Creating a protective coating at temperatures up to 265°C

Key advantages for international buyers:

- Lowest cost among surface finishes

- Excellent shelf life (12+ months)

- Thermal stress testing during application

- Reworkable and repairable

Important considerations: Not suitable for fine-pitch components (<0.5mm), potential for uneven surfaces, and thermal shock risks.

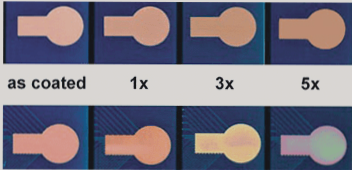

2. Immersion Tin (ISn): The Flat Surface Solution

For high-density interconnect (HDI) PCBs, Immersion Tin offers superior flatness through chemical deposition. This lead-free alternative is ideal for:

- Press-fit pin insertion applications

- Projects requiring RoHS compliance

- Situations demanding precise surface uniformity

“Immersion Tin provides excellent surface planarity for BGA and QFN components, making it a preferred choice for modern electronics manufacturing.” – WellCircuits Technical Team

Procurement considerations: Requires careful handling, limited reflow cycles, and potential tin whisker formation over time.

3. OSP/Entek: The Eco-Friendly Option

Organic Solderability Preservative (OSP) represents the most environmentally conscious choice among PCB surface finishes. This water-based coating:

- Forms molecular bond with copper

- Maintains excellent surface flatness

- Complies with strict environmental regulations

Best applications: Consumer electronics, cost-sensitive projects, and quick-turn prototypes.

Export considerations: Short shelf life (3-6 months), not suitable for plated through-holes, and requires careful handling during shipping.

4. ENIG: The Industry Standard for High-End Applications

Electroless Nickel Immersion Gold (ENIG) dominates premium PCB manufacturing with its dual-layer protection:

- Nickel layer (120-240μin) as diffusion barrier

- Thin gold coating (2-8μin) for oxidation resistance

Why global buyers choose ENIG:

- Excellent for plated through-holes

- Long shelf life (12+ months)

- RoHS and REACH compliant

- Ideal for complex, high-density designs

Cost factors: 30-50% more expensive than HASL, non-reworkable, and requires precise process control.

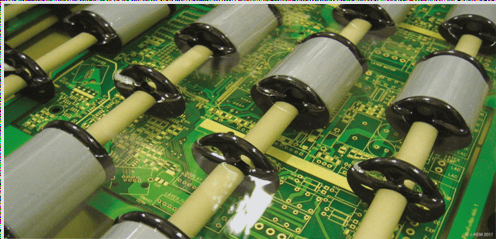

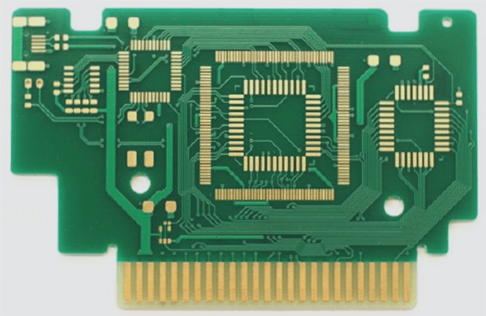

5. Hard Gold: The Durable Specialist Finish

For connector-heavy applications and high-wear environments, electroplated hard gold over nickel delivers unmatched durability:

- Ideal for edge connectors and contact points

- Controlled thickness through plating cycles

- Exceptional wear resistance

Key specifications:

- Typical thickness: 5-50μin

- Hardness: 150-200 HK25

- Not recommended for solderable areas

Expert Recommendations for International Buyers

When sourcing PCBs from China manufacturers, consider these factors for optimal surface finish selection:

- Project budget: HASL vs. premium finishes

- Component density: Fine-pitch requirements

- Environmental compliance: RoHS/REACH needs

- Product lifecycle: Shelf life requirements

- Assembly process: Reflow cycles needed

Streamline Your PCB Procurement with WellCircuits

Our online PCB quote system provides instant pricing for standard specifications, while our engineering team stands ready to advise on custom surface finish solutions for specialized applications.

Next steps for global buyers:

- Get instant pricing through our online portal

- Consult with our technical team for complex projects

- Leverage our export expertise for seamless international shipping