Flex-Rigid PCB Manufacturing Excellence: Advanced Solutions for Global Electronics

Why Flex-Rigid PCBs Dominate Modern Electronics

In today’s interconnected world, printed circuit boards (PCBs) power everything from consumer gadgets to aerospace systems. While rigid PCBs remain fundamental components, flexible PCB technology has revolutionized design possibilities with superior space efficiency, dynamic bendability, and enhanced thermal performance. At Wellcircuits, we specialize in high-performance flex-rigid PCB manufacturing that meets the most demanding international standards.

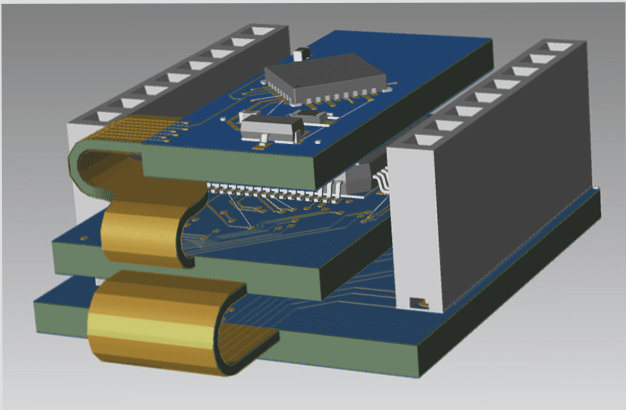

Understanding Flex-Rigid PCB Technology

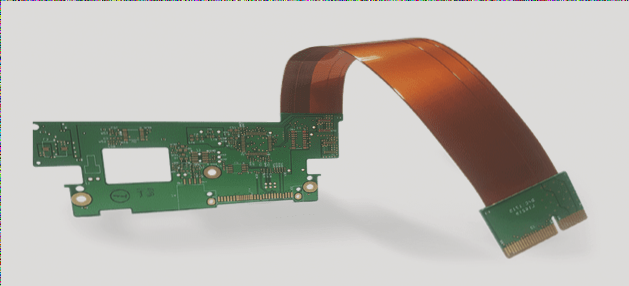

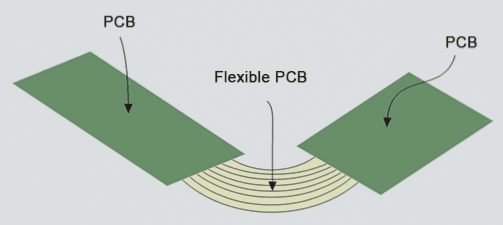

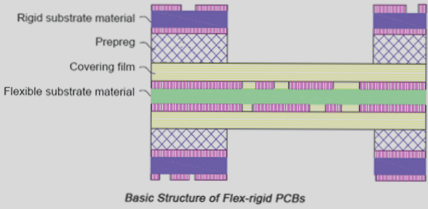

What makes flex-rigid PCBs different? These hybrid solutions combine the structural stability of rigid boards with the adaptability of flexible circuits, creating 3D interconnection capabilities unmatched by traditional PCBs.

Core Material Selection for Optimal Performance

- Polyimide Films: The industry standard for flexible dielectrics, offering exceptional thermal stability (up to 400°C) and mechanical durability

- Fluoropolymer Substrates: Critical for high-frequency PCB applications in military and aerospace systems

- Advanced Adhesive Systems: Precision bonding solutions that maintain integrity across thermal cycles

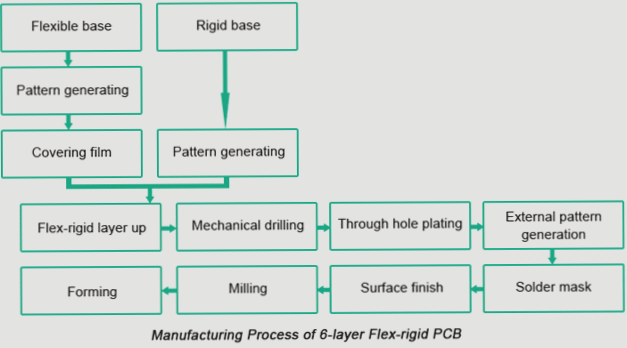

Advanced Manufacturing Processes at Wellcircuits

1. Precision Flex-Rigid Fabrication

Our China-based PCB manufacturing facility utilizes cutting-edge processes:

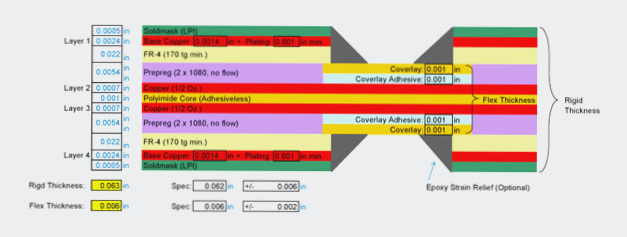

“The transition from traditional FR4 stacking to modern polyimide-acrylic composite structures has reduced board thickness by 40% while improving thermal dissipation.”

2. Embedded Flexible Circuit Technology

For clients requiring high-density interconnect (HDI) solutions, we offer:

- Blind/buried via configurations for space-constrained designs

- Material-efficient production methods reducing waste by up to 30%

- Impedance-controlled layouts for RF/microwave applications

Global Applications of Flex-Rigid PCBs

Our solutions power innovation across industries:

- Medical devices: Miniaturized implants and diagnostic equipment

- Aerospace systems: Vibration-resistant avionics

- Automotive electronics: Flexible circuits for next-gen vehicles

- IoT devices: Compact, durable connectivity solutions

Streamlined Global Procurement Process

As a leading PCB manufacturer in China, we’ve simplified international ordering:

- Instant online quoting for standard specifications

- Dedicated engineering support for complex projects

- Logistics solutions optimized for export compliance

Ready to Upgrade Your Electronics?

Discover why global brands trust Wellcircuits for their flex-rigid PCB manufacturing needs. Our expertise in high-frequency PCB solutions and complex multilayer designs ensures your products outperform the competition.