Preventing Technical Problems When Using Flexible PCBs: Best Practices for International Buyers

Avoiding Delays in Quick-Turn Flexible PCB Orders: Key Challenges and Solutions

When sourcing flexible PCB manufacturers in China for international trade, incomplete design data and technical oversights frequently cause production delays. As a global exporter of high-reliability flex circuits, we’ve identified the most common pitfalls and how to prevent them.

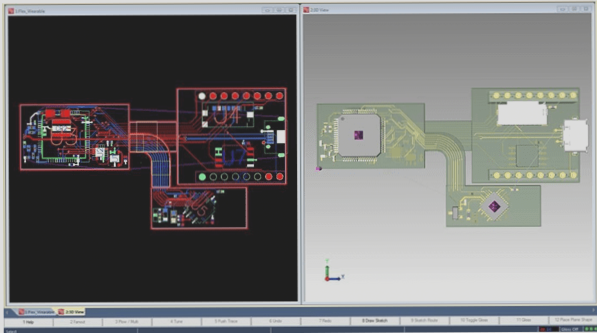

1. Submitting Complete Design Data: The Foundation of Successful Production

How to prepare perfect PCB files for manufacturing: Your data package must include:

- Fully verified Gerber files (RS-274X preferred)

- Detailed mechanical drawings with all specifications

- Complete material stack-up including:

- Copper weight requirements (½ oz vs 1 oz for current capacity)

- Dielectric thickness preferences

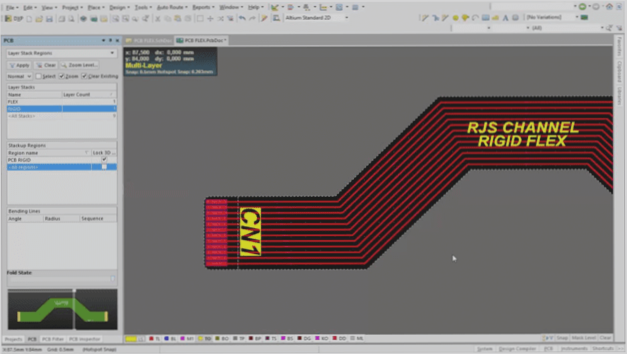

- Flexible vs rigid areas demarcation

“International buyers often underestimate copper weight specifications. For dynamic flex applications, we recommend ½ oz copper for optimal flexibility.”

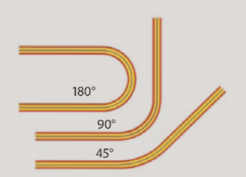

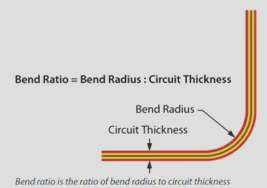

2. Mechanical Bend Requirements: Designing for Real-World Use

Best flexible PCB design for bend applications requires:

- Clear documentation of all bend locations

- Accurate radius specifications (minimum bend radius = 6x material thickness)

- Dynamic vs static bend classification

For high-flex PCB applications, consider:

- Neutral axis positioning

- Conductor routing perpendicular to bend axis

- Reinforcement of transition areas

3. IPC-2223 Compliance: Critical Design Rules for Flexible Circuits

Following IPC flex circuit design standards prevents these common issues:

| Design Element | Best Practice | Risk if Ignored |

|---|---|---|

| Component Areas | Use polyimide stiffeners | Solder joint failure |

| Bend Near Components | Maintain 5mm clearance | Mechanical stress |

| Vias in Flex Zones | Avoid or use tear relief | Crack formation |

| Trace Corners | 45° or curved transitions | Copper fatigue |

4. ZIF Connector Specifications: Ensuring Reliable Interconnections

How to specify ZIF contacts correctly: Your design must include:

- Precise finger location coordinates

- Coverlay opening dimensions (±0.1mm tolerance)

- Stiffener thickness matching connector specs

- Manufacturer part numbers for verification

Advanced Considerations for Export-Quality Flexible PCBs

For international buyers requiring specialty flex circuits, consider these additional specifications:

- EMI shielding: Single/double-sided ground layers

- Adhesive systems: PSA selection for enclosure mounting

- High-temperature materials: For automotive/industrial applications

- Impedance control: Critical for RF applications

Conclusion: Streamlining Your Flexible PCB Procurement Process

By addressing these common flex PCB manufacturing challenges upfront, international buyers can ensure:

- Faster turnaround times (2-3 week standard lead times)

- Higher first-pass yield rates (>98%)

- Reduced total cost of ownership

- Reliable performance in end applications

For complex projects, we recommend early engagement with your PCB manufacturer’s engineering team to review designs before production. This collaborative approach prevents 85% of potential delays in our experience serving global clients.