Flexible Printed Circuits: Types, Advantages, and Global Applications by WellCircuits

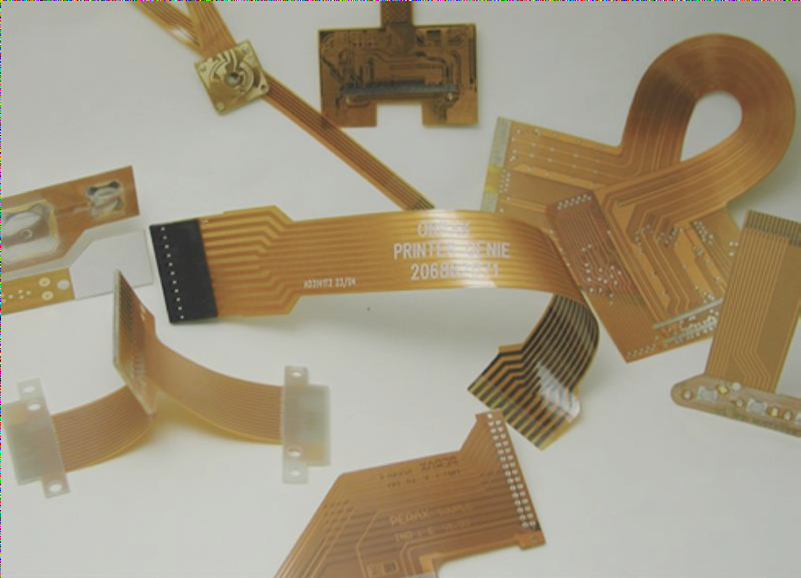

In today’s rapidly evolving electronics industry, flexible printed circuits (FPCs) have become indispensable components for advanced technological applications. As a leading PCB manufacturer in China, WellCircuits specializes in high-performance flexible circuit solutions for global markets.

Comprehensive Guide to Flexible Circuit Types

Understanding the different types of flexible circuits is crucial for selecting the optimal solution for your application. Here’s our expert breakdown of the major FPC categories:

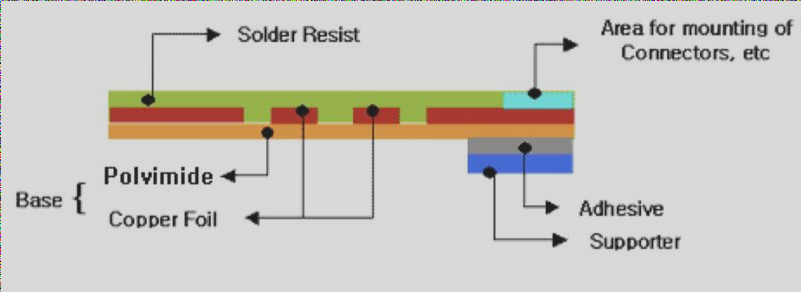

1. Single-Sided Flexible Circuits

The most cost-effective solution for simple applications, featuring:

- Single conductive copper layer on polyimide substrate

- Optional coverlay for enhanced protection

- Ideal for static applications requiring one-time bending

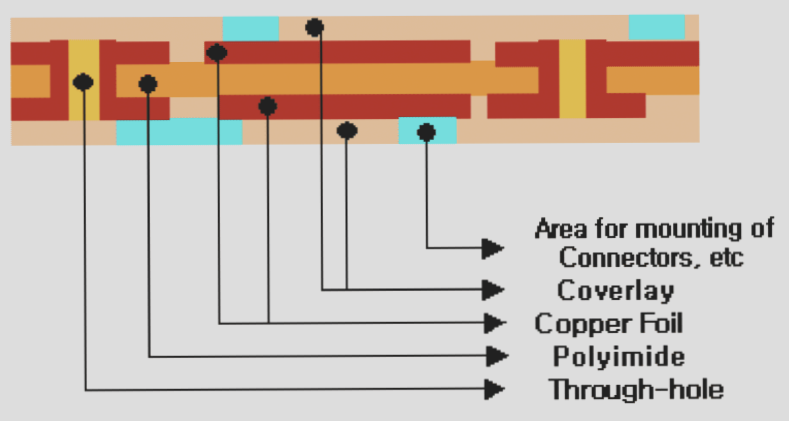

2. Double-Sided Flex Circuits

Our high-density interconnect solutions offer:

- Conductive layers on both sides of dielectric material

- Plated through-hole (PTH) technology for layer interconnection

- Superior signal integrity for complex designs

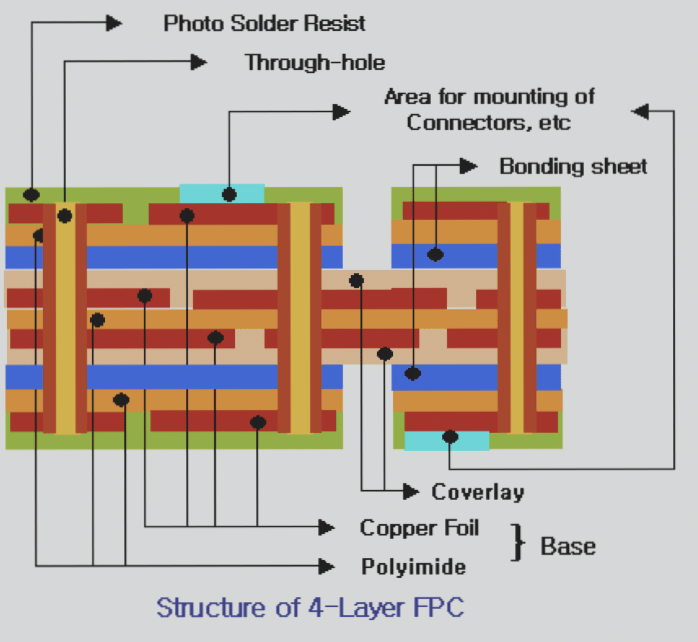

3. Multilayer Flexible Circuits

For demanding applications requiring:

- 3+ conductive layers with dielectric isolation

- Advanced via technologies for layer interconnection

- High component density with SMT compatibility

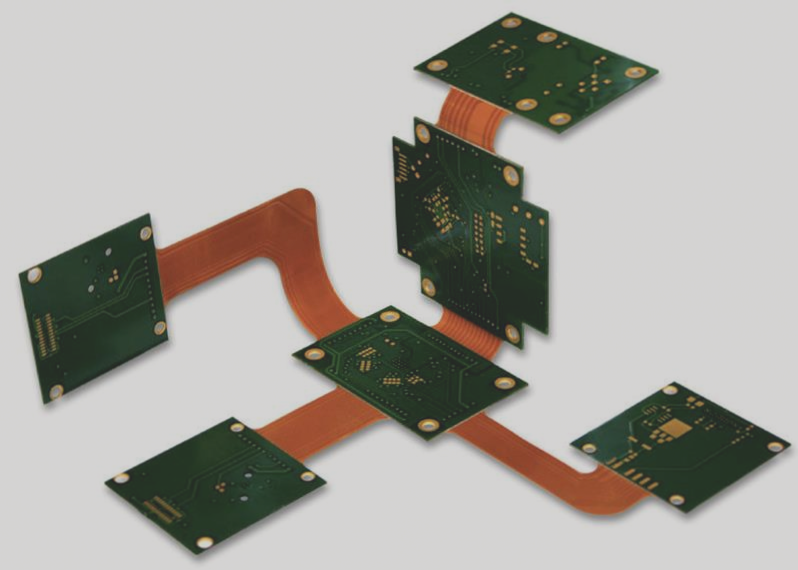

4. Rigid-Flex Circuits

The ultimate hybrid solution combining:

- Rigid PCB stability with flexible circuit adaptability

- Reduced interconnection points for enhanced reliability

- Superior vibration resistance for harsh environments

Advanced Materials for Superior Performance

As a premier flexible PCB manufacturer in Shenzhen, WellCircuits utilizes cutting-edge materials:

- Conductors: High-purity copper (1oz-3oz), aluminum, and specialty inks

- Dielectrics: Polyimide (12.5-125μm), PET, and PEN films

- Adhesives: Epoxy, acrylic, and PSA options for various applications

- Surface Finishes: ENIG, immersion silver, OSP, and carbon printing

Why Choose Flexible Circuits for Your Global Operations?

“Flexible circuits represent the future of electronic interconnects, offering unparalleled design freedom and reliability for international markets.” – WellCircuits Engineering Team

The advantages of flexible printed circuits make them ideal for global export applications:

- Space & Weight Reduction: Up to 75% lighter than traditional wiring

- Enhanced Reliability: Fewer interconnects mean higher MTBF

- Dynamic Flex Capability: Withstands millions of bend cycles

- Thermal Management: Superior heat dissipation characteristics

- Cost Efficiency: Reduced assembly time and labor costs

Global Applications of Flexible Circuits

From medical devices to aerospace systems, our FPCs power innovation worldwide:

Industrial Applications

- Robotic arms and automation systems

- Industrial sensors and control systems

- Barcode scanners and HMI interfaces

Consumer Electronics

- Foldable smartphones and wearables

- HD cameras and display systems

- Advanced audio equipment

Medical Technology

- Implantable devices and patient monitors

- Diagnostic imaging equipment

- Portable medical devices

Aerospace & Defense

- Avionics systems and satellite communications

- Military-grade navigation equipment

- Drone and UAV technologies

WellCircuits: Your Trusted Global PCB Partner

As one of the best PCB manufacturers in China, WellCircuits offers:

- 100,000+ sqm state-of-the-art manufacturing facility

- ISO 9001, IATF 16949, and UL certified production

- Custom flexible circuit solutions for international markets

- Competitive pricing with rapid turnaround times

How to Order Flexible Circuits from WellCircuits

Our streamlined process makes international PCB procurement simple:

- Submit your design files (Gerber, ODB++)

- Receive DFM analysis and engineering feedback

- Get competitive quote within 24 hours

- Approval and production launch

- Global shipping with full documentation

Contact our flexible circuit experts today to discuss your project requirements and discover why global brands trust WellCircuits for their advanced PCB solutions.