Advanced PCBA Manufacturing: Global Solutions for Printed Circuit Board Assembly

In today’s competitive electronics manufacturing landscape, understanding Printed Circuit Board Assembly (PCBA) processes is critical for businesses sourcing high-quality electronic components from China. This comprehensive guide explores professional PCB assembly services with insights into industrial-grade manufacturing techniques used by leading providers like Wellcircuits.

Understanding PCBA: Core Components and Requirements

PCBA (Printed Circuit Board Assembly) represents the complete process of populating a bare PCB with electronic components to create functional circuitry. Unlike basic PCB manufacturing which produces the blank board, PCBA transforms the foundation into operational electronics.

Essential PCBA Requirements:

- High-quality printed circuit boards (single, double, or multi-layer)

- Precision electronic components (SMDs, through-hole, or mixed technology)

- Advanced soldering materials (lead-free solder paste, solder wire)

- Industrial flux formulations for optimal bonding

- State-of-the-art assembly equipment (pick-and-place machines, reflow ovens)

- Comprehensive inspection systems (AOI, X-ray, ICT testing)

Comprehensive PCBA Process Technologies

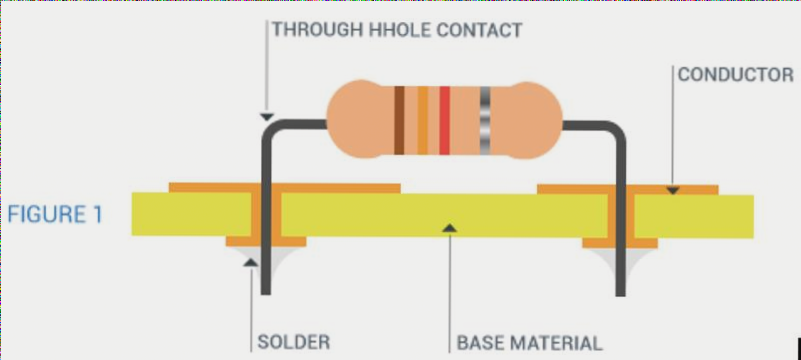

1. Through-Hole Technology (PTH)

Traditional plated through-hole assembly remains vital for high-reliability applications where mechanical stability is paramount. This method is particularly valuable for:

- Military and aerospace electronics

- Industrial control systems

- Power supply units

Wave Soldering Process Flow:

- Component insertion into pre-drilled holes

- Flux application for optimal solder adhesion

- Preheating to prevent thermal shock

- Wave soldering for permanent connections

- Post-solder cleaning and inspection

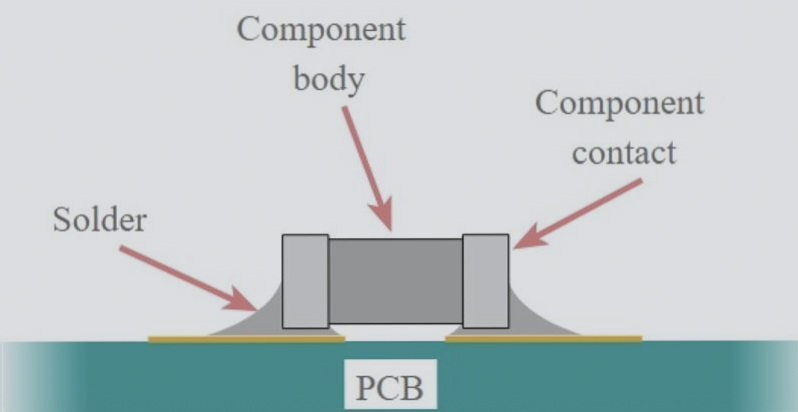

2. Surface Mount Technology (SMT)

Modern SMT assembly services dominate high-volume production with advantages including:

- Higher component density

- Faster production speeds

- Improved consistency

- Lower profile assemblies

SMT Assembly Workflow:

- PCB preparation and solder paste application

- Precision component placement with high-speed pick-and-place machines

- Reflow soldering for permanent connections

- Automated optical inspection (AOI)

- Functional testing and quality assurance

Why Choose Wellcircuits for Your PCBA Requirements?

As a leading PCB manufacturer in China, Wellcircuits offers comprehensive solutions for global buyers seeking:

- Competitive PCB assembly services China pricing

- ISO-certified manufacturing facilities

- RoHS-compliant materials and processes

- Rigorous quality control protocols

- Flexible order quantities from prototypes to mass production

“Our turnkey PCB assembly services handle everything from component sourcing to final testing, ensuring seamless integration with your supply chain.”

Advanced Testing and Quality Assurance

Wellcircuits implements multiple verification stages including:

- Automated Optical Inspection (AOI)

- X-ray inspection for BGA components

- In-Circuit Testing (ICT)

- Functional Testing (FCT)

- Environmental stress screening

Global Export Capabilities

Our China-based PCB manufacturing facility serves international clients with:

- Efficient logistics networks

- Customs-compliant documentation

- Flexible shipping options

- Multilingual technical support

For businesses seeking reliable PCB assembly partners, Wellcircuits combines technical expertise with competitive manufacturing solutions tailored for global markets.