The Ultimate Guide to Aluminum PCBs: Benefits, Applications, and Manufacturing Insights

Aluminum Printed Circuit Boards (PCBs) represent a breakthrough in electronic component technology, offering superior thermal management and durability for demanding applications. Also known as Metal Clad PCBs, Thermally Conductive PCBs, or IMS (Insulated Metal Substrate) boards, these specialized circuits have become essential in modern electronics manufacturing.

Why Choose Aluminum PCBs for Your Electronic Projects?

Developed in the 1970s for amplification hybrid integrated circuits, aluminum PCBs now serve critical roles across industries due to their:

- Exceptional heat dissipation capabilities

- Superior dimensional stability under thermal stress

- Enhanced power density and product longevity

- Cost-effective solution for high-power applications

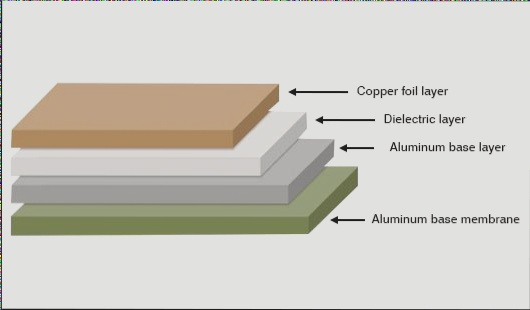

Structural Composition of High-Performance Aluminum PCBs

The advanced four-layer architecture of aluminum PCBs delivers unmatched performance:

1. Copper Foil Layer (1oz-10oz)

Thicker than standard FR4 PCBs, this layer enables higher current carrying capacity – ideal for power electronics and LED applications.

2. Thermally Conductive Dielectric Layer (50μm-200μm)

This critical component features low thermal resistance, efficiently transferring heat from components to the aluminum base.

3. Aluminum Base Layer

The core thermal management component with high thermal conductivity properties.

4. Protective Aluminum Membrane

Available in standard (120°C) or high-temperature (250°C) variants, this layer prevents surface damage during manufacturing and operation.

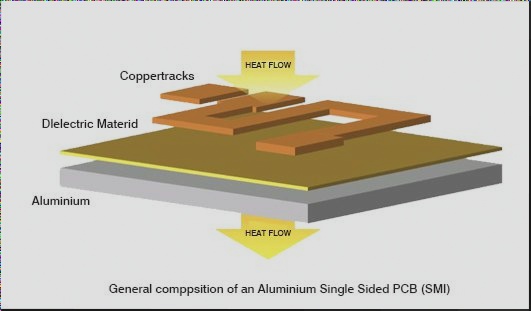

Performance Advantages Over Traditional FR4 PCBs

“Aluminum PCBs demonstrate 10-20x better thermal performance than standard FR4 boards, making them indispensable for power electronics and LED applications.”

Thermal Management Breakthroughs

- Thermal resistance of just 1-2°C/W (vs. 20-22°C/W for FR4)

- Matched CTE (Coefficient of Thermal Expansion) between aluminum (22ppm/°C) and copper (18ppm/°C)

- Minimal dimensional change (2.5-3.0%) across 30-140°C temperature range

Additional Performance Benefits

- Enhanced product lifespan through superior heat dissipation

- Compact design possibilities with higher power density

- Effective electromagnetic shielding properties

- High dielectric strength for improved reliability

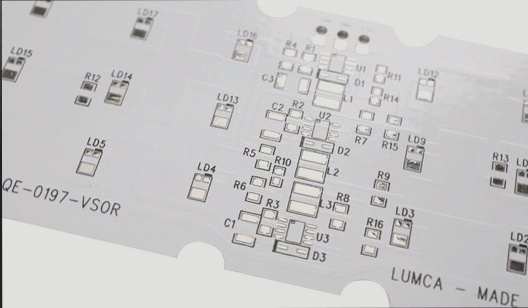

Aluminum PCB Types for Specific Applications

1. Universal Aluminum PCBs

Featuring epoxy glass fiber pre-preg dielectric layers, these boards offer cost-effective thermal solutions for standard applications.

2. High Thermal-Conductive Aluminum PCBs

With specialized epoxy resin dielectrics, these boards deliver maximum heat transfer for power electronics and high-current applications.

3. High-Frequency Aluminum PCBs

Utilizing polyolefin or polyimide resin dielectrics, these boards maintain signal integrity in RF and microwave applications.

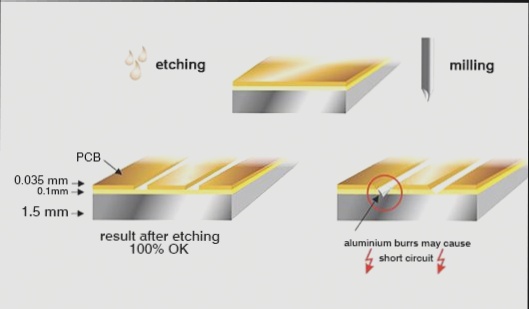

Manufacturing Challenges and Solutions

Precision Copper Etching

Thicker copper foils (3oz+) require careful width compensation during etching to maintain trace dimensional accuracy. WellCircuits’ advanced manufacturing processes ensure precise trace geometry control.

Solder Mask Application

Our two-stage solder mask printing process overcomes the challenges of thick copper traces, utilizing:

- High-quality solder mask oils

- Strategic resin filling techniques

- Precision alignment systems

Mechanical Processing

Specialized techniques prevent common issues in aluminum PCB fabrication:

- Optimized drilling parameters to eliminate burrs

- Electric milling for via formation

- Professional-grade milling cutters

Why Choose WellCircuits for Your Aluminum PCB Needs?

As a leading PCB manufacturer in China, WellCircuits offers:

- ISO 9001:2015 certified production facilities (17,000+ M²)

- UL, REACH, RoHS, and CE certified products

- Specialization in quick-turn prototypes and medium-volume production

- Expertise across multiple industries including:

- Data communication systems

- Medical electronics

- Industrial control systems

- Aerospace/military applications

For high-quality, cost-effective aluminum PCB solutions, request your instant quote from WellCircuits today.