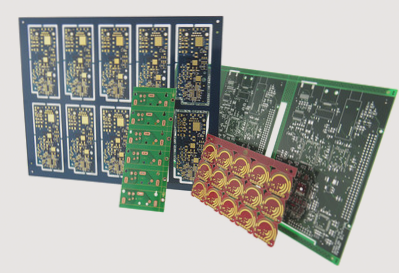

Comparing the Top 4 PCB Surface Finishes: Technical Advantages for Global Export Markets

What Is PCB Surface Finish in Electronics Manufacturing?

In modern PCB manufacturing technology, surface finish serves as the critical intermetallic layer between bare copper circuits and electronic components. As a leading PCB manufacturer in China, we understand how surface treatment impacts solderability, corrosion resistance, and long-term reliability – key factors for international electronics buyers sourcing from global suppliers.

How Surface Finish Selection Impacts PCB Performance

When evaluating how to choose PCB surface finish, engineers must consider three visual indicators: gold (highest grade), silver (mid-range), and light red (economy). These finishes directly reflect manufacturing quality – a crucial consideration when importing PCBs from China for mission-critical applications.

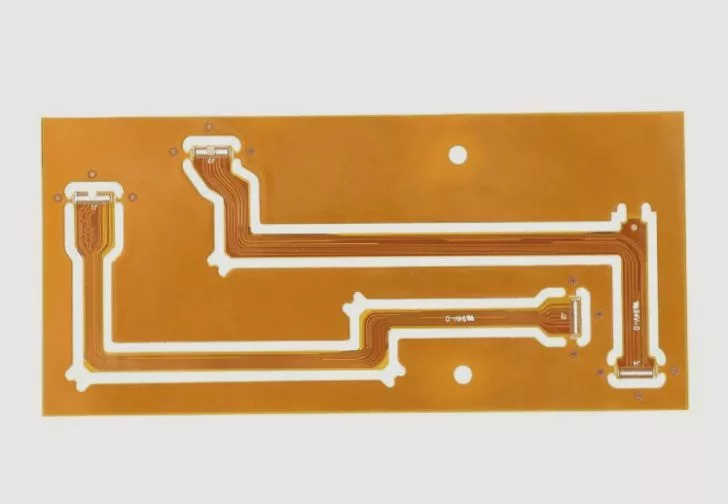

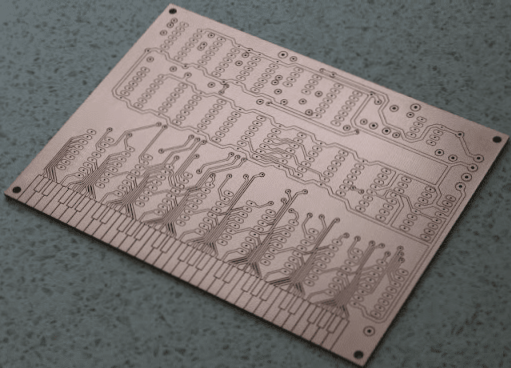

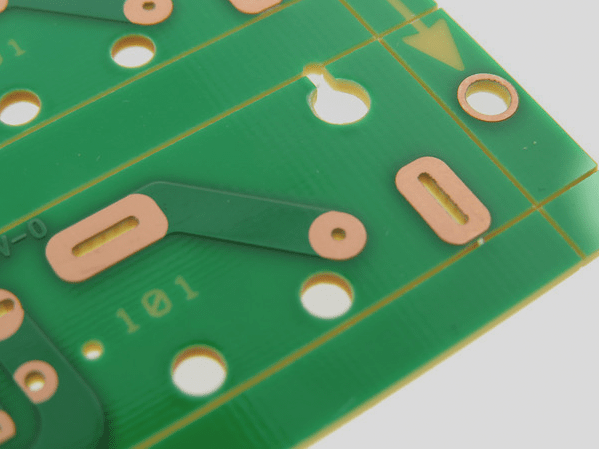

1. Bare Copper PCB: Cost-Effective but Limited

Bare copper remains popular for low-cost PCB prototypes and simple circuits, offering:

- Advantages:

- Lowest material cost among finishes

- Excellent initial solderability

- Ideal for quick-turn prototypes

- Disadvantages:

- 2-hour oxidation window after unpacking

- Unsuitable for double-sided boards

- Requires solder paste for test points

“For export-oriented PCB production, bare copper demands strict humidity control during shipping and storage – a key consideration for international buyers.”

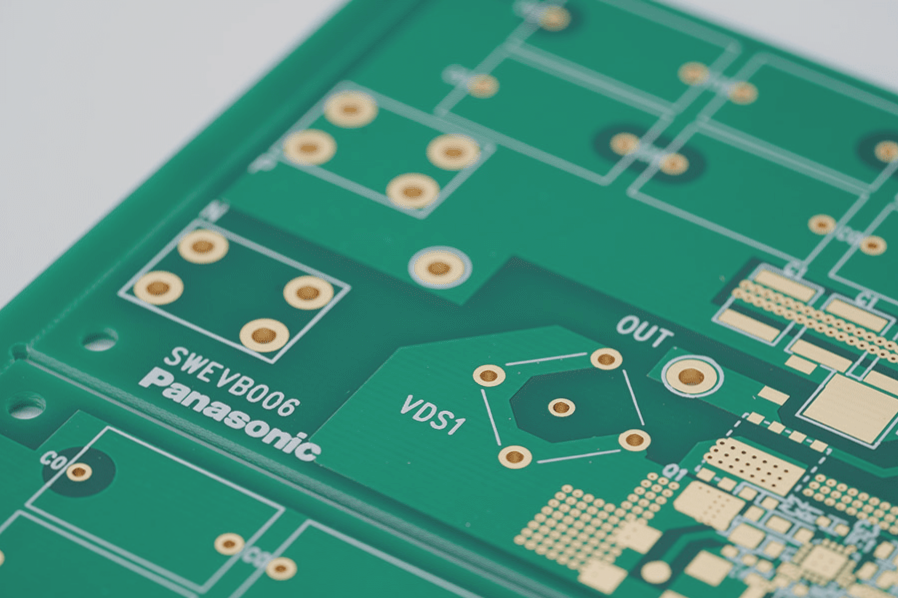

2. ENIG (Electroless Nickel Immersion Gold): Premium Global Standard

As gold-plated PCB manufacturers in Shenzhen specializing in high-end boards, we recommend ENIG for:

- Key Benefits:

- Oxidation resistance for long shelf life

- Superior flatness for fine-pitch components

- Multiple reflow capability (ideal for complex PCB assembly)

- Trade-offs:

- 10-15% higher material cost

- Potential “black pad” nickel corrosion

- Requires expert process control

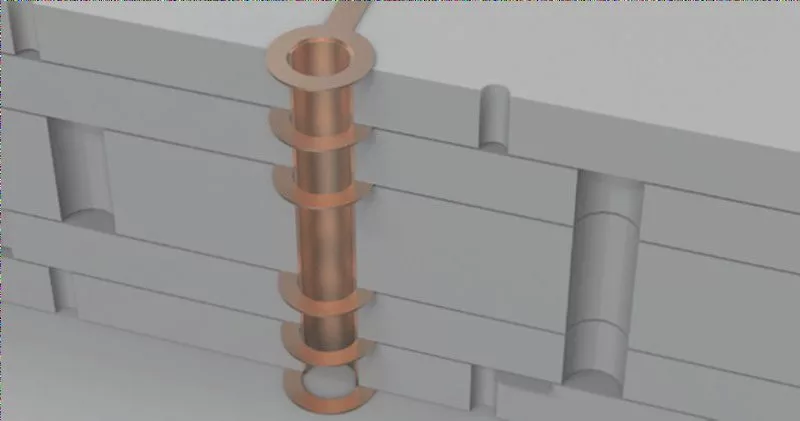

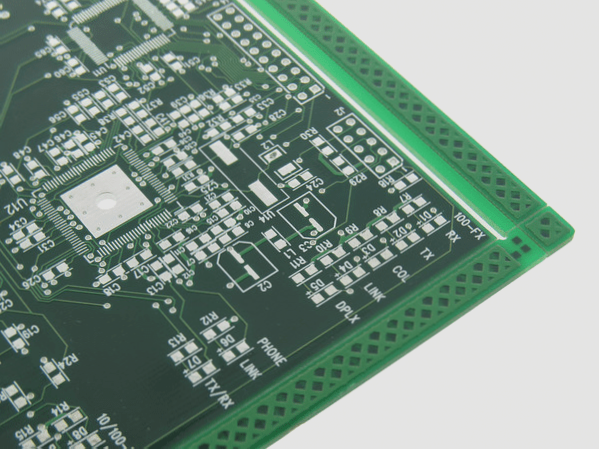

3. HASL (Hot Air Solder Leveling): Budget-Friendly Option

For cost-sensitive PCB buyers needing reliable lead-free surface finishes, HASL offers:

- Advantages:

- Most economical finish option

- Excellent initial solderability

- Widely available globally

- Limitations:

- Poor surface flatness

- Solder bead risks with fine-pitch parts

- Not ideal for double-sided SMT

4. OSP (Organic Solderability Preservative): Niche Solution

When evaluating best PCB finish for large boards, OSP provides unique benefits:

- Pros:

- Lower cost than immersion gold

- Allows rework of expired boards

- Maintains bare copper solderability

- Cons:

- 3-month maximum shelf life

- 24-hour processing window after opening

- Requires test point modification

Strategic Finish Selection for Export Success

As trusted PCB suppliers for international trade, we recommend:

- High-reliability applications: ENIG for medical/military exports

- Cost-driven consumer electronics: Lead-free HASL

- Quick-turn prototypes: Bare copper with proper handling

- Large-format boards: OSP with strict timeline management

Understanding these PCB surface treatment technologies helps global buyers make informed sourcing decisions when importing circuit boards from China. Each finish presents unique advantages for different applications, price points, and reliability requirements in the international electronics market.