Understanding Copper Thieving in PCB Manufacturing: Techniques and Benefits

Copper thieving is an essential technique in multilayer PCB production, designed to optimize plating uniformity and enhance electromagnetic compatibility (EMC). This method strategically places copper equalizing blocks in specific areas such as outer graphic zones, PCB assembly auxiliary strips, and panel manufacturing sections. But what makes copper thieving in PCB fabrication so crucial for international electronics manufacturers?

Why Copper Thieving Matters in PCB Production

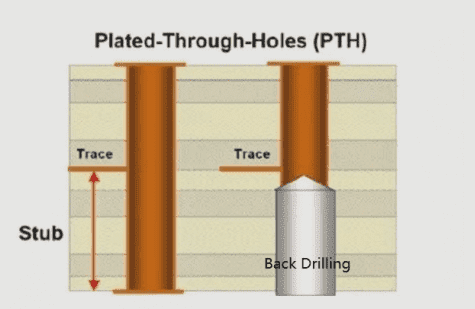

During PCB electroplating, maintaining balanced plating currents is critical to prevent uneven copper thickness. Without proper current distribution, inconsistent plating can lead to signal integrity issues and reduced product reliability. Copper thieving techniques draw excess current from concentrated copper foil areas, ensuring:

- Uniform current distribution across the PCB

- Improved impedance control for high-speed circuits

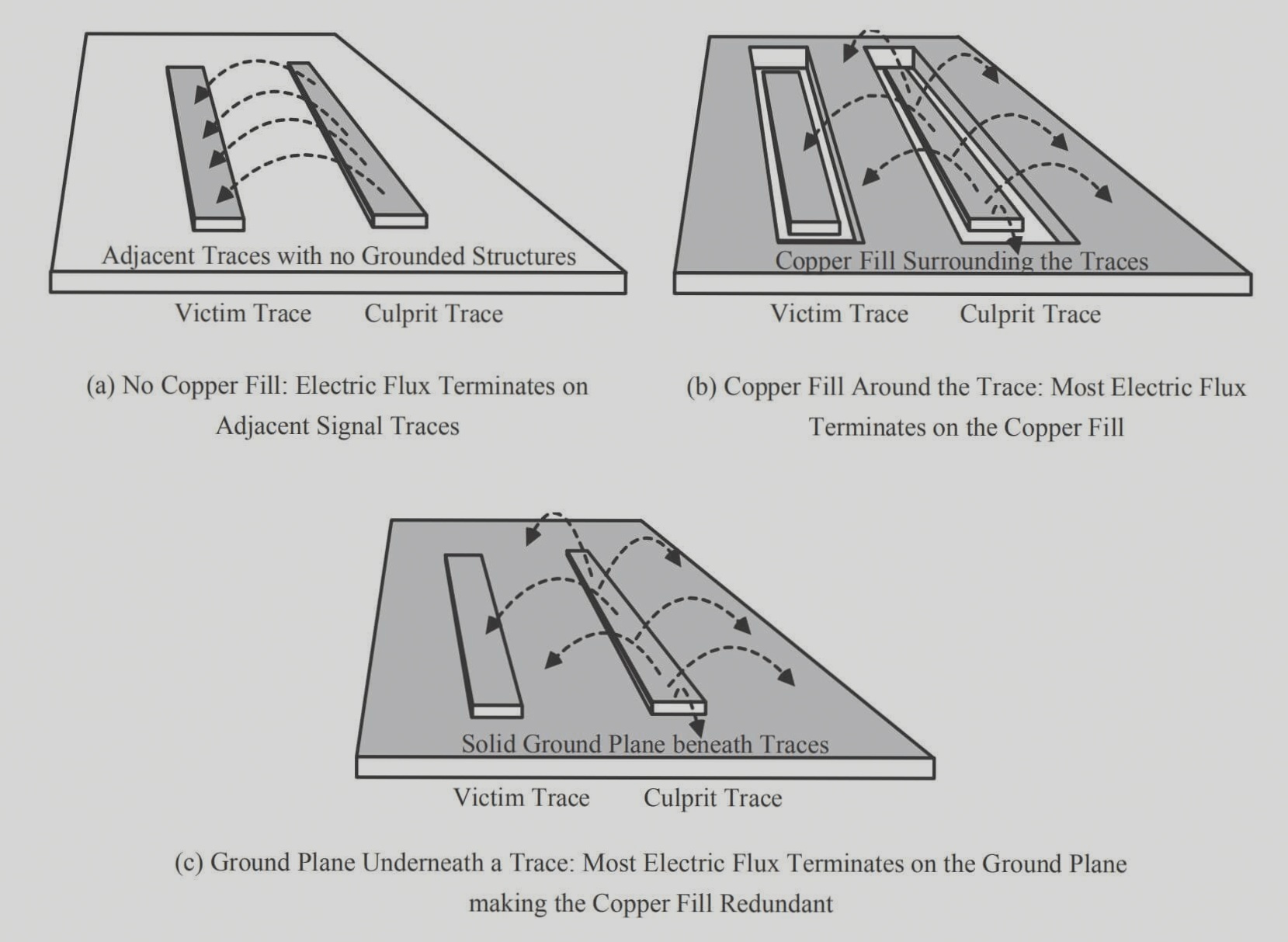

- Reduced crosstalk between traces

- Enhanced EMC performance for global compliance

Copper Thieving vs. Traditional Copper Cladding

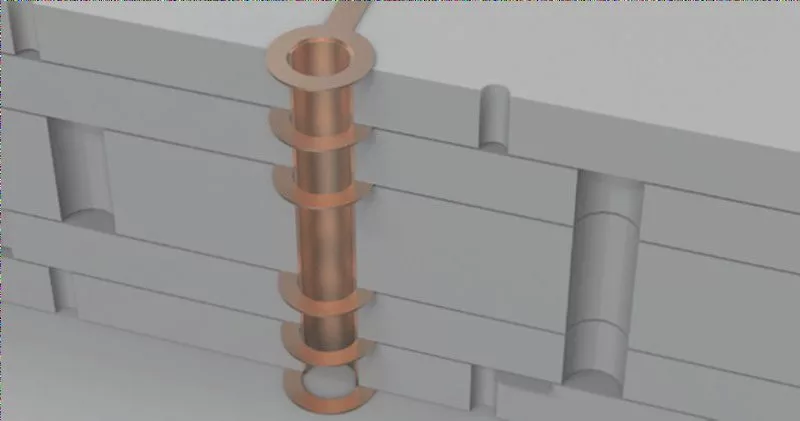

While large-area copper cladding benefits high-impedance analog circuits, it can harm high-speed digital PCB designs. Unlike solid copper planes, copper thieving blocks consist of small, isolated square copper pieces that:

- Prevent antenna effects that cause EMI radiation

- Maintain signal integrity in dense digital layouts

- Allow better thermal management in multilayer boards

“For PCB manufacturers in China serving global markets, proper copper thieving implementation is key to meeting international EMC standards while maintaining cost efficiency.”

Best Practices for Implementing Copper Thieving

When applying copper thieving for impedance control, consider these critical factors:

- Use chessboard or dot patterns in high-density areas (BGA zones, main control sections)

- Ensure no impedance-sensitive traces run beneath thieving blocks

- Connect copper blocks to 0V reference through additional vias

- Verify impact through CAM software or EDA tools like Cadence Allegro

Optimizing PCB Performance for Global Export Markets

For international PCB buyers and electronics manufacturers, understanding copper thieving techniques offers competitive advantages:

- Improved yield rates for high-volume production

- Better compliance with EU and US EMC regulations

- Enhanced signal integrity in 5G and IoT devices

- Reduced manufacturing defects in complex multilayer PCBs

As China PCB manufacturers continue leading global electronics exports, mastering advanced techniques like copper thieving becomes crucial for maintaining quality standards in international trade. Whether you’re designing high-frequency PCBs or cost-effective consumer electronics, proper copper balancing ensures reliable performance across all market segments.