Professional PCB Multilayer Board Pressing Process: A Comprehensive Guide for Export Businesses

Understanding the PCB Multilayer Board Manufacturing Process

For international electronics manufacturers and PCB sourcing professionals, understanding the multilayer board pressing process is crucial for quality assurance. This guide explores key techniques used by professional PCB manufacturers in China, offering insights into advanced lamination methods that ensure reliable circuit board performance.

Autoclave Pressing: The Industry Standard

The autoclave pressing method utilizes high-temperature saturated water vapor under pressure to test delamination resistance in laminated substrates. This PCB quality control process, also known as the pressure cooker test, remains a best practice for multilayer board manufacturers worldwide. An alternative approach using high-pressure carbon dioxide (the cabin press method) delivers similar results for high-frequency PCB production.

Evolution of Lamination Techniques

Modern PCB fabrication plants have moved beyond traditional cap lamination methods to more efficient processes:

- Foil lamination method – Direct pressing of copper foil with film substrates

- Mass lamination (Mass Lam) – High-volume production solution

- Automated lay-up systems – Minimizing human error in alignment

Critical Quality Considerations in PCB Pressing

When evaluating Chinese PCB suppliers for export business, watch for these common pressing defects:

Surface Imperfections

- Creases – Wrinkles in thin copper layers (<0.5 oz)

- Dents/Dish Down – Surface depressions affecting signal integrity

“For high-speed PCB applications, surface imperfections can cause impedance variations leading to signal noise. Top-tier PCB manufacturers in Shenzhen implement strict quality controls to prevent these issues.”

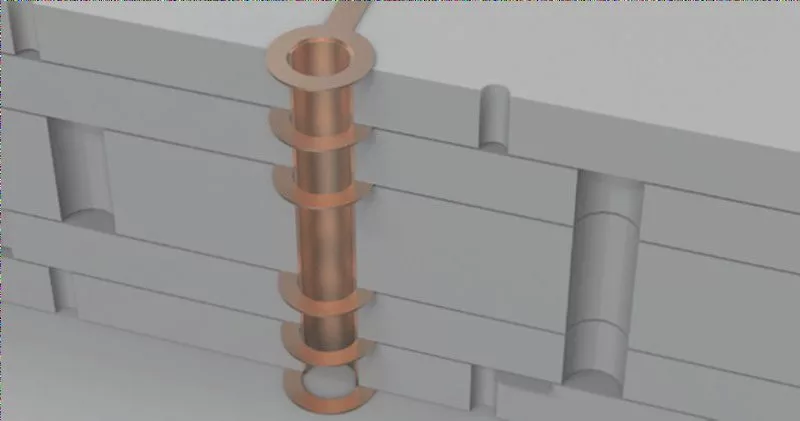

Essential Pressing Components

Quality multilayer PCB production requires specialized materials:

- Caul plates (AISI 430/630 stainless steel) – For material separation

- Kraft paper (90-150 lb) – Heat transfer buffer material

Optimized Pressing Parameters

Understanding how to optimize PCB lamination helps buyers evaluate manufacturer capabilities:

Pressure Management

- Kiss pressure (15-50 PSI) – Initial low pressure phase

- Full pressure (300-500 PSI) – Final bonding pressure

Environmental Controls

Premium PCB factories in China maintain:

- Clean room facilities for lay-up processes

- Precise temperature/humidity controls

- Automated material handling systems

Selecting the Right PCB Manufacturing Partner

When sourcing multilayer PCBs for export, consider these factors:

- Experience with high-layer count boards

- Implementation of automated lay-up systems

- Quality certifications for international electronics standards

- Capacity for high-volume PCB production

Leading PCB manufacturers in Guangdong combine these advanced pressing techniques with rigorous quality control to deliver boards that meet global export requirements for reliability and performance.