Optimizing PCB Circuit Design for LED Switching Power Supplies: A Global Manufacturer’s Guide

The Critical Role of PCB Design in Modern LED Power Supply Systems

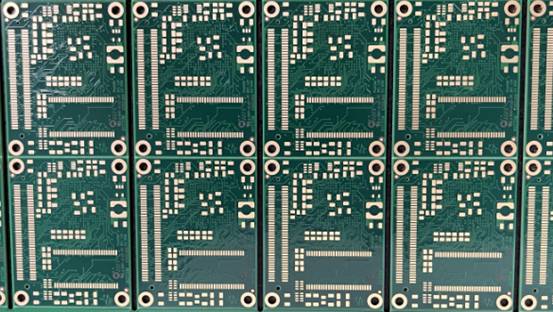

Recent advancements in LED switching power supply technology have accelerated product development cycles, making proper PCB circuit design more crucial than ever. As the final engineering stage before production, PCB layout directly impacts electromagnetic compatibility (EMC), thermal performance, and overall system reliability – key concerns for international electronics buyers sourcing from Chinese power supply manufacturers.

Why PCB Design Matters for Global Export Quality

- EMI Reduction: Proper layout minimizes electromagnetic interference – critical for meeting international compliance standards

- Thermal Management: Optimal component placement prevents hot spots that reduce product lifespan

- Manufacturing Yield: Design-for-manufacturing principles lower defect rates in high-volume production

- Endurance Testing: Robust designs withstand rigorous reliability testing demanded by global clients

Four Essential Current Loops in Switching Power Supply PCBs

Every high-efficiency LED driver PCB contains four critical current pathways that require careful engineering:

- Input Source Current Loop: DC charging path through input capacitors

- Power Switch AC Loop: High-frequency switching path with trapezoidal current waves

- Output Rectifier AC Loop: Secondary-side conversion circuit

- Output Load Current Loop: Clean DC output path to LED arrays

“In our experience supplying LED power solutions to 37 countries, proper loop routing reduces EMI by up to 60% compared to conventional layouts.” – Senior PCB Engineer, Global Export Division

Best Practices for Loop Layout in Export-Grade Designs

When designing for international market requirements, follow these proven techniques:

- Place filter capacitors closest to their respective loops

- Minimize parallel trace lengths between high-frequency components

- Implement star grounding for mixed-signal circuits

- Use multi-layer boards with dedicated power planes for high-current applications

Step-by-Step PCB Layout Methodology for LED Drivers

Our China-based manufacturing team follows this optimized workflow when creating export-quality PCB designs:

- Transformer Placement: Central positioning with adequate creepage/clearance

- Power Switch Routing: Shortest possible paths with proper thermal relief

- Rectifier Circuit Design: Optimized for minimal switching losses

- Control Circuit Integration: Isolated from noisy power sections

- Input Filter Implementation: Compliant with global EMI standards

Advanced Techniques for Competitive Global Products

Leading LED power supply manufacturers in China now implement these cutting-edge approaches:

- 3D component placement simulations for thermal optimization

- Automated impedance matching for high-frequency circuits

- AI-assisted trace routing for EMI reduction

- Design-for-test features enabling faster production validation

Meeting International Standards with Robust PCB Design

Our export-oriented design process ensures compliance with:

- UL/cUL (North America)

- CE (Europe)

- CCC (China)

- KC (Korea)

- PSE (Japan)

For global buyers seeking reliable LED driver solutions, proper PCB engineering forms the foundation of product quality. By implementing these professional design methodologies, manufacturers can deliver power supplies that meet the exacting standards of international markets while maintaining competitive production costs.