How to Choose the Right PCB Board: A Guide to Common Materials for Export Businesses

Printed Circuit Boards (PCBs) form the backbone of modern electronics, serving as the critical platform for component interconnection and signal transmission. For export-oriented manufacturers and international electronics buyers, selecting the appropriate PCB material significantly impacts product performance, durability, and compliance with global standards.

Key Considerations When Selecting PCB Materials

Before exploring specific materials, understand these critical selection factors for international trade compliance:

- Thermal management requirements for target markets

- Dielectric properties matching application frequencies

- Mechanical stress tolerance for shipping and handling

- RoHS and REACH compliance for EU exports

- Cost-effectiveness for high-volume production

Top 5 PCB Materials for Export-Quality Electronics

1. FR-4: The Industry Standard for General Applications

The FR-4 epoxy laminate remains the most exported PCB material globally, offering balanced performance for cost-sensitive electronics manufacturing. Key advantages include:

- Excellent electrical insulation (10^6-10^7 Ω·cm volume resistivity)

- Good thermal resistance (Tg 130-180°C)

- Multiple thickness options (0.2mm-3.2mm)

- RoHS-compliant formulations available

“For PCB buyers in Europe and North America, always verify FR-4 material certificates for halogen-free compliance.” – Global Sourcing Expert

2. Aluminum Substrate PCBs: Thermal Management Solutions

Ideal for LED lighting exports and power electronics, aluminum-backed PCBs provide:

- Superior heat dissipation (5-10 W/mK thermal conductivity)

- Enhanced durability for industrial applications

- Weight reduction versus traditional metal enclosures

3. CEM-1/CEM-3: Cost-Effective Alternatives

These paper-reinforced phenolic materials offer budget-friendly options for:

- Consumer electronics with short product lifecycles

- Single-layer PCB designs

- Non-critical temperature applications

4. High-Frequency Laminates: RF and Microwave Solutions

Essential for 5G equipment manufacturers and aerospace electronics, these materials feature:

- Ultra-low dielectric loss (Df 0.001-0.005)

- Stable dielectric constant across frequencies

- PTFE-based formulations for high-reliability applications

5. Flexible PCBs: For Advanced Electronics Design

Growing in demand for wearable technology exports, flexible circuits provide:

- 3D packaging capabilities

- Vibration resistance for automotive electronics

- Weight reduction in portable devices

Expert Recommendations for Global Buyers

When sourcing PCBs from China or other manufacturing hubs, consider:

- Verify UL certification for North American markets

- Request material test reports for all shipments

- Evaluate thermal cycling performance for harsh environments

- Confirm IPC-6012 Class 2/3 compliance for critical applications

FAQs: PCB Material Selection for Export

What’s the best PCB material for high-temperature applications?

For automotive under-hood electronics or industrial equipment, consider polyimide flex circuits or high-Tg FR-4 variants with Tg >170°C.

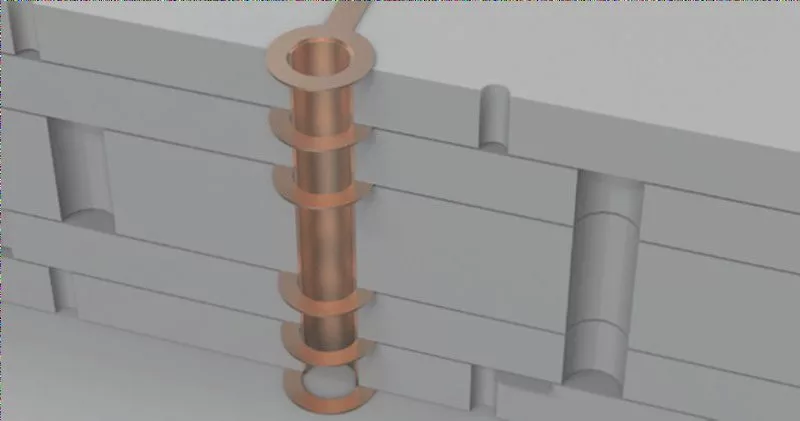

How do I choose between aluminum and copper substrates?

Aluminum offers better cost-performance ratio for most LED lighting exports, while copper provides superior thermal conductivity for high-power RF applications.

Which PCB material has the best moisture resistance for tropical climates?

PTFE-based high-frequency materials and properly sealed FR-4 boards perform best in high-humidity export markets.

Partnering with Reliable PCB Manufacturers

When establishing long-term PCB supply chains, prioritize manufacturers with:

- Proven export documentation capabilities

- Experience with your target markets’ compliance requirements

- Multi-material production capacity

- Responsive engineering support

By understanding these PCB material fundamentals, international electronics buyers can make informed decisions that optimize performance, compliance, and total cost of ownership for their global operations.