How to Identify a Reliable and Trustworthy PCB Assembly Manufacturer for Your Global Supply Chain

In today’s competitive electronics manufacturing landscape, finding the best PCB assembly service for international buyers requires careful consideration of both quality and cost factors. While many engineers search for “how to reduce PCB assembly costs,” prioritizing price alone can compromise product reliability and project timelines.

6 Strategic Approaches to High-Quality, Cost-Effective PCB Assembly

1. Selecting a Certified PCB Assembly Partner in China

When evaluating PCB assembly manufacturers in China, consider these critical factors:

- International certifications: ISO 9001, IATF 16949, RoHS, and UL compliance

- Advanced manufacturing capabilities including high-precision SMT equipment

- Component sourcing networks for global supply chain efficiency

- Experience with export documentation and international shipping

2. Design Optimization for Manufacturing Efficiency

Implement Design for Manufacturing (DFM) principles to reduce costs without sacrificing quality:

- Optimize layer count and board dimensions

- Select appropriate surface finishes for international shipping conditions

- Standardize via technologies where possible

3. Creating a Comprehensive Bill of Materials (BOM)

A well-prepared BOM is essential for smooth international procurement:

“Include alternative component options to mitigate global supply chain disruptions and account for long lead times in international trade.”

4. Streamlined Component Procurement Strategy

When working with overseas PCB manufacturers, consider:

- Full turnkey vs. consignment assembly options

- Manufacturer’s relationships with global component distributors

- Tariff and customs considerations for international shipments

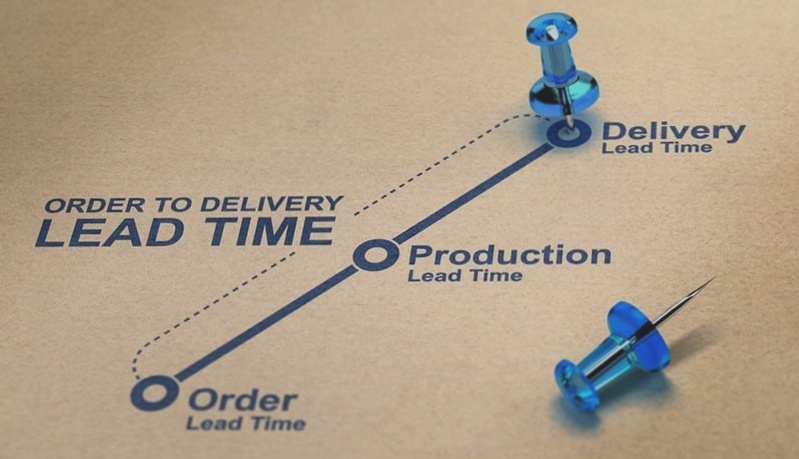

5. Strategic Order Volume Planning

Optimize your international PCB procurement through:

- Economic order quantity calculations for global logistics

- Buffer stock planning for longer international lead times

- Seasonal demand forecasting for export markets

6. Rigorous Quality Assurance for International Standards

Ensure your PCB assembly service provider offers:

- IPC-A-610 compliance testing

- Automated optical inspection (AOI) capabilities

- Environmental stress testing for export conditions

Building Long-Term Partnerships with PCB Assembly Experts

Developing relationships with trusted PCB manufacturers in China offers numerous benefits for international buyers:

- Consistent quality across multiple production runs

- Priority treatment during global component shortages

- Improved communication through established protocols

- Volume pricing advantages for export quantities

Key Considerations for International PCB Procurement

When evaluating how to choose a PCB assembly manufacturer for export, remember these critical factors:

- Manufacturer’s experience with international trade compliance

- Capability to handle multilingual documentation and specifications

- Understanding of import/export regulations in your target markets

- Flexibility to accommodate different international quality standards

Conclusion: Balancing Cost and Quality in Global PCB Sourcing

Finding the best PCB assembly service for international buyers requires a strategic approach that considers both immediate costs and long-term reliability. By implementing these practices, you can establish productive relationships with trusted PCB manufacturers in China while ensuring consistent quality for your global customer base.