Six Software-Based Methods for PCBA Hardware Version Identification in Global Electronics Manufacturing

In today’s competitive international electronics trade, proper PCBA version control is critical for maintaining product consistency, tracking improvements, and ensuring software-hardware compatibility. As a leading PCBA manufacturer in China, we present six proven methods to identify hardware versions through software solutions.

Why PCBA Version Management Matters for Global Buyers

Effective PCBA version tracking delivers tangible benefits for international procurement teams:

- Simplifies supply chain management for electronics importers

- Reduces compatibility issues in global distribution

- Enables precise firmware matching for OEM partners

- Provides audit trails for quality control compliance

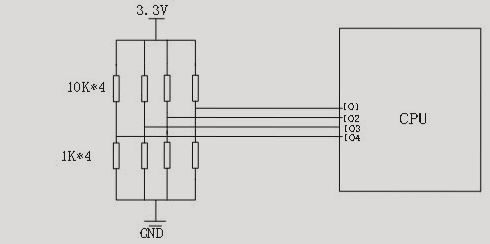

1. GPIO Pull-Up Resistor Method

This cost-effective solution is ideal for budget-conscious electronics buyers seeking simple version control:

“For buyers sourcing high-volume consumer electronics, the GPIO method offers the best ROI for basic version identification needs.”

Implementation Advantages:

- Ultra-low BOM cost (just pennies per unit)

- Simple firmware integration

- Ideal for high-volume PCB assembly orders

Trade-Offs to Consider:

- Limited version capacity (16 versions max with 4 pins)

- Not suitable for complex global supply chain requirements

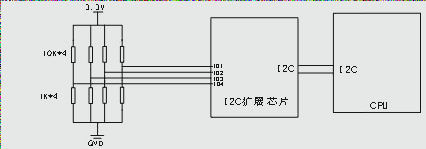

2. I2C GPIO Expansion Technique

When searching for how to manage multiple PCBA versions in sophisticated products, this method solves GPIO limitations:

Key Benefits for Export Buyers:

- Supports 256 versions with single-chip solution

- Maintains compatibility with existing I2C infrastructure

- Preferred by industrial electronics manufacturers

Procurement Considerations:

- Adds $0.08-$0.30 to unit cost

- Requires stable I2C implementation

3. AD Sampling Voltage Method

For buyers seeking best version control solution for analog devices, this approach leverages existing AD pins:

Supply Chain Advantages:

- Minimal component requirements

- Flexible version scaling via resistor values

- Common in automotive electronics manufacturing

Global Sourcing Notes:

- Verify CPU AD pin availability early in RFQ process

- Requires precise voltage regulation

4. Flash Memory Storage Solution

This software-centric approach answers how to implement flexible version control without hardware changes:

Benefits for International Buyers:

- Zero additional hardware cost

- Enables post-production version updates

- Preferred for IoT device manufacturers

Quality Assurance Factors:

- Implement robust write protection

- Include validation checks in firmware

5. EEPROM-Based Version Tracking

For reliable PCBA version identification in harsh environments, this balanced solution delivers:

Export-Ready Features:

- High reliability for industrial equipment exports

- Field-upgradeable version information

- Cost-effective for mid-range products

Procurement Best Practices:

- Specify EEPROM with sufficient write cycles

- Validate communication stability

6. OTP Chip Implementation

When absolute version security is required, this method provides tamper-proof PCBA identification:

Security Advantages:

- Permanent version locking

- Immune to firmware corruption

- Essential for medical device compliance

Sourcing Considerations:

- Finalize versions before production

- Maintain chip inventory for revisions

Selecting the Right Version Control Method

When evaluating PCBA suppliers in China for your export needs, consider these factors:

| Method | Best For | Cost Impact |

|---|---|---|

| GPIO | High-volume consumer goods | $0.02-$0.05 |

| I2C Expansion | Complex industrial systems | $0.08-$0.30 |

| OTP | Regulated medical devices | $0.01-$0.10 |

For global electronics buyers, understanding these version control methods ensures you select the optimal solution for your product lifecycle and compliance requirements.