Choosing PCB Materials for High-Power RF Applications: A Guide for Export Businesses

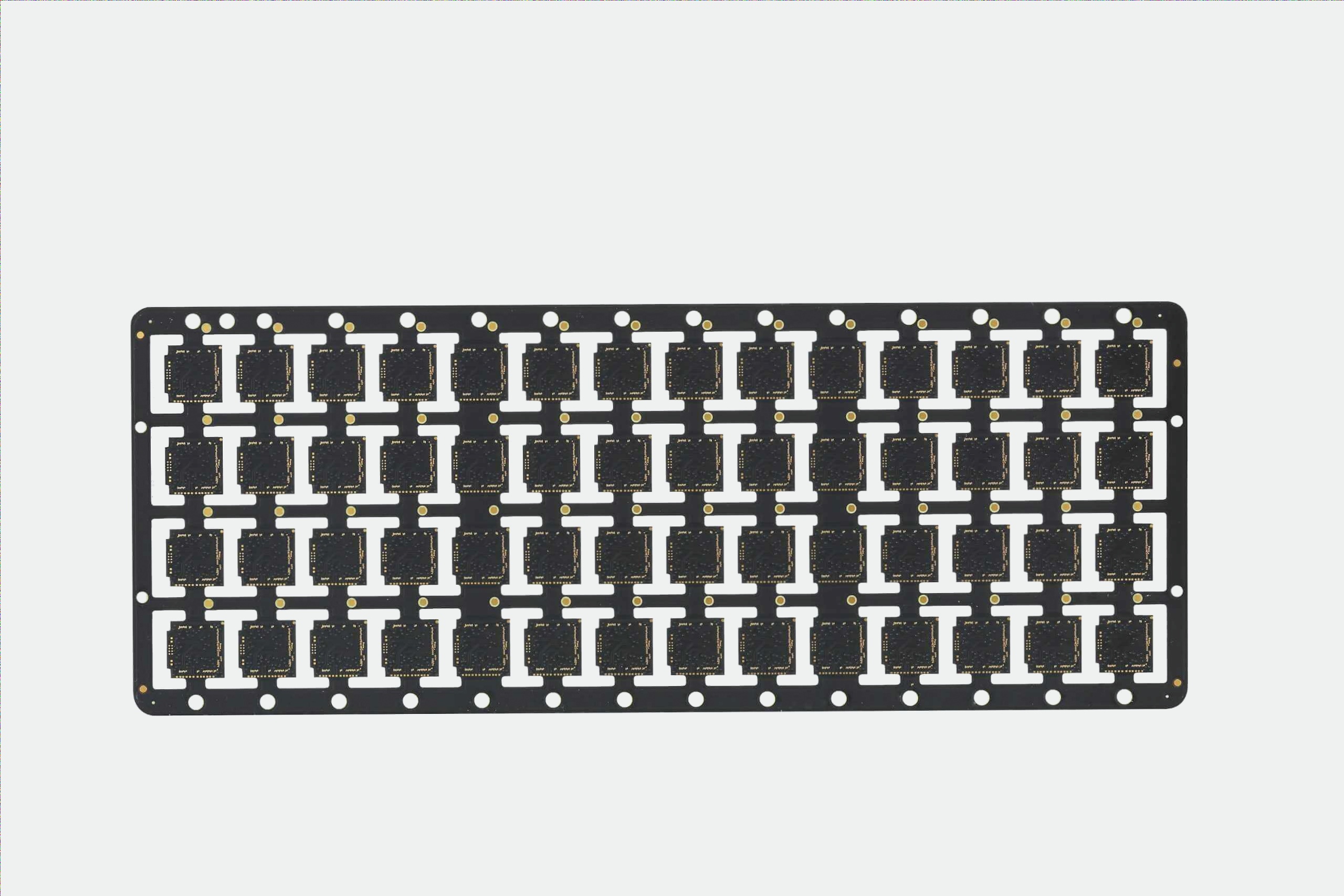

In the rapidly evolving landscape of high-power RF applications, particularly in mobile base station technology, selecting the right PCB materials is critical for performance and reliability. This guide explores key considerations for international trade businesses sourcing high-frequency PCB laminates from PCB manufacturers in China and other global suppliers.

Thermal Management in High-Power RF PCBs

One of the most significant challenges in RF power amplifier design is effective thermal management. The relationship between loss and heat generation is fundamental:

- Higher circuit losses generate more heat under high RF power

- Frequency-dependent heating compounds thermal challenges

- Temperature fluctuations affect dielectric constant (Dk) and its thermal coefficient (TCDk)

For export businesses sourcing PCB materials for 5G infrastructure, understanding these thermal dynamics is essential when evaluating suppliers.

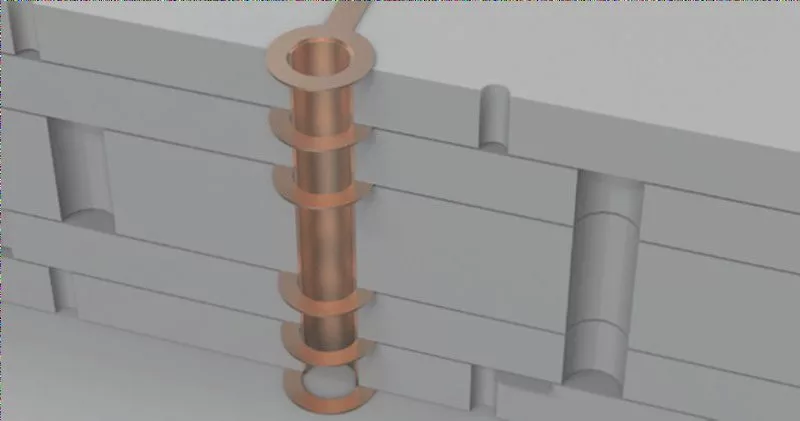

Key Material Properties for Heat Dissipation

When selecting high-power RF PCB materials, consider these critical properties:

- Dissipation factor (Df): Lower values indicate better performance

- Insertion loss: Includes dielectric, conductor, radiation, and leak losses

- Copper surface roughness: Affects conductor loss at the copper-substrate interface

“The best PCB materials for high-frequency applications combine low Df, smooth copper surfaces, and high thermal conductivity.” – RF Engineering Expert

How to Choose RF PCB Materials for Base Stations

For international buyers sourcing PCB materials for telecom infrastructure, these factors are crucial:

- Evaluate the material’s thermal conductivity

- Assess copper surface quality and roughness

- Consider the thermal coefficient of dielectric constant (TCDk)

- Verify frequency stability across operating ranges

Frequency-Heat Relationship in RF Applications

The interaction between frequency and heat generation is particularly important for 5G base station PCBs:

- Higher frequencies generate more heat at equivalent power levels

- Dielectric and conductor losses increase with frequency

- Skin effect becomes more pronounced at higher frequencies

This makes thermal management in high-frequency PCBs a critical consideration for telecom equipment manufacturers and their suppliers.

TCDk: The Overlooked Critical Parameter

The thermal coefficient of dielectric constant (TCDk) significantly impacts:

- Stability of power amplifier circuits

- Performance of 1/4 wavelength matching networks

- Overall system efficiency in varying temperatures

For export businesses dealing with RF PCB materials, understanding TCDk specifications helps in selecting the right materials for specific climate conditions.

Best Practices for Material Selection

When sourcing high-power RF PCB materials from Chinese manufacturers or global suppliers:

- Prioritize materials with low Df and smooth copper

- Verify thermal conductivity specifications

- Evaluate TCDk values for temperature stability

- Consider application-specific requirements

- Collaborate with material providers for technical support

By following these guidelines, international trade businesses can source optimal PCB materials for RF power applications that meet the demanding requirements of modern telecommunications infrastructure.