Innovative Advances in PCB Copper Foil Technology for Global Export Markets

Superior Performance of VLP and LP Copper Foil in PCB Manufacturing

When sourcing high-performance PCB copper foil for international trade, Very Low Profile (VLP) and Low Profile (LP) copper foils offer distinct advantages over standard electrolytic copper cylinders. These advanced materials are increasingly sought after by PCB manufacturers in China and global electronics producers for their enhanced structural integrity and processing benefits.

Key Technical Advantages for Export-Grade Copper Foil

- Crystalline structure optimization prevents grain sliding, delivering superior tensile strength in both normal and thermal states

- Fine surface topography reduces copper powder residue during etching – critical for high-frequency PCB applications

- Enhanced thermal stability prevents recrystallization in multi-layer lamination processes

- Precision etching characteristics enable finer circuit production with reduced side erosion

Why Global Buyers Choose LP Copper Foil for Advanced PCB Production

As a leading copper foil manufacturer in China, we understand international buyers need materials that address multiple technical challenges simultaneously. LP copper foil provides solutions for:

“The growing demand for high-density interconnect (HDI) PCBs requires copper foils that maintain dimensional stability while enabling finer circuit patterns. Our LP technology meets these exacting requirements for export markets.”

Critical Performance Metrics for Export Quality

- Drillability enhancement for multi-layer boards and laser drilling applications

- Improved signal integrity through uniform thickness and controlled impedance

- Surface flatness retention post-lamination for precision circuitry

- Noise reduction between layers and traces

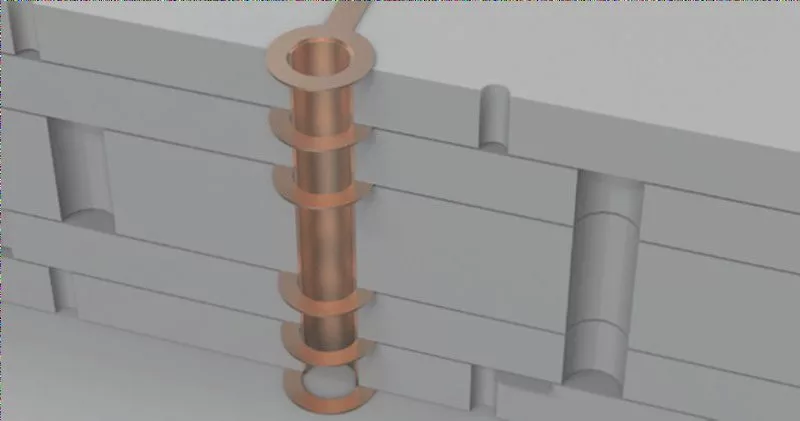

Breakthroughs in Ultra-Thin Copper Foil Technology

The best copper foil for micro-via PCBs requires advanced manufacturing capabilities. Current production benchmarks include:

- Industrialized production of 9μm, 5μm and 3μm foils in Japan and U.S. markets

- Innovative carrier solutions for ultra-thin copper foil manufacturing

- Film-type carriers offering superior peelability and handling characteristics

Technical Challenges in Ultra-Thin Foil Production

When evaluating how to choose PCB copper foil suppliers, international buyers should consider these critical factors:

- Carrier-based production yield rates

- Advanced carrier material development

- Consistency in micron-level thickness control

- Compatibility with CO2 laser etching processes

Global Applications and Market Opportunities

Our export-grade copper foil solutions serve diverse international applications:

- Multi-layer boards with micro-buried/blind vias

- Organic resin packaging substrates for portable electronics

- High-frequency communication equipment

- Automotive electronics requiring extreme reliability

With continuous improvements in grain structure and orientation control, China copper foil manufacturers are delivering world-class materials that meet the most demanding international specifications while offering competitive export pricing structures.