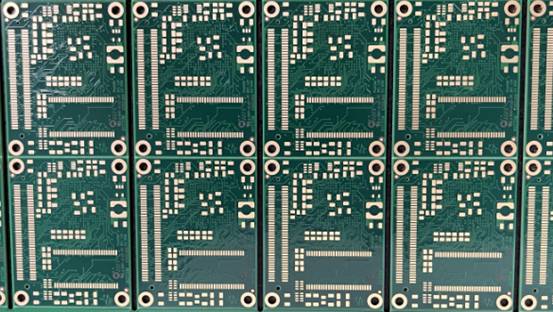

Copper Clad Laminate Raises the Bar for Epoxy Resin Performance in HDI Multilayer Boards

Understanding HDI Multilayer Board Technical Development

The evolution of HDI multilayer boards plays a pivotal role in determining the performance requirements for substrate materials in modern electronics manufacturing. Key characteristics include:

- Innovative design approaches for high-density interconnects

- Diverse manufacturing process methodologies

- Strong practical application focus

- Direct correlation with material technology advancements

For businesses seeking HDI multilayer board manufacturers in China, understanding these technical parameters is essential for selecting optimal copper clad laminate (CCL) solutions.

Impact on High-Performance Copper Clad Laminate Technology

The rapid development of HDI technology has created significant transformations in the CCL industry:

Key Market Shifts

- Increased product diversification to meet specialized applications

- Enhanced manufacturer specialization in high-frequency CCL solutions

- Growing demand for balanced performance characteristics

- Accelerated product development cycles

“The synergy between HDI board advancement and CCL technology is creating unprecedented opportunities in global PCB exports.” – Industry Expert

Strategic Approaches for Epoxy Resin Manufacturers

To support the high-performance CCL market, resin producers should consider:

Product Development Strategies

- Creating serialized epoxy resin formulations for diverse CCL applications

- Developing specialty resin compositions for high-frequency boards

- Establishing brand-specific resin solutions for PCB manufacturers

Industry Collaboration Models

The most successful epoxy resin suppliers for CCL production are transitioning from basic coordination to full integration with PCB material manufacturers, creating streamlined supply chains for international electronics exporters.

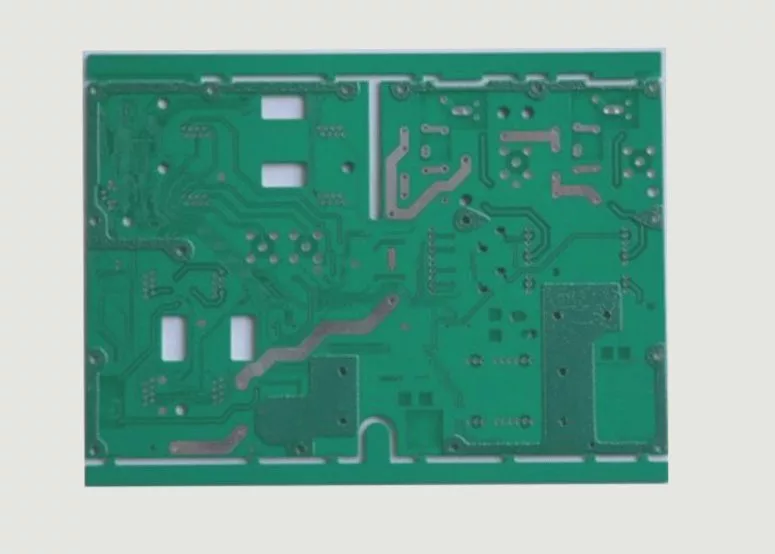

Critical Challenges in Substrate Material Development

As HDI technology progresses, material manufacturers face several technical hurdles:

- Maintaining reliability with increasingly narrow conductive circuits

- Ensuring performance in micro-via applications

- Developing ultra-thin insulating layers without compromising durability

- Meeting high-temperature reliability requirements

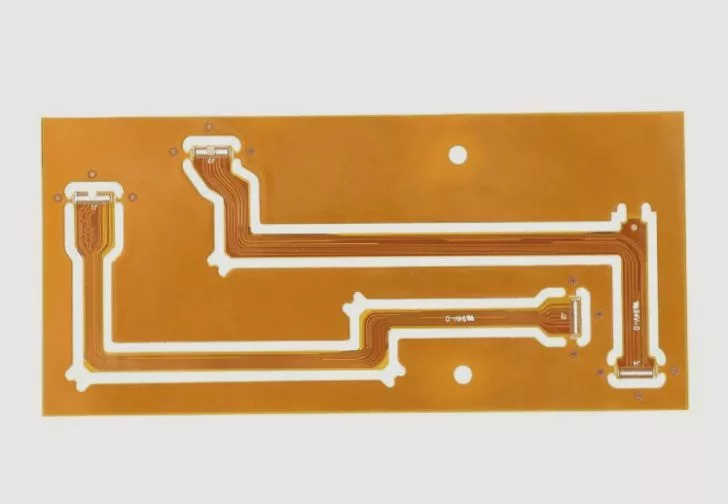

Future Trends in HDI Multilayer Board Technology

The next generation of HDI development will focus on:

Technical Advancements

- Sub-micron circuit precision for high-density PCB designs

- Advanced micro-via formation techniques

- Nanoscale insulating layer technologies

Material Science Breakthroughs

Leading CCL manufacturers in Asia are investing heavily in research to develop:

- Next-generation dielectric materials

- Advanced copper foil treatments

- Thermally stable resin systems

For companies exploring how to select copper clad laminates for HDI applications, these advancements will significantly impact material selection criteria and performance expectations in the coming years.