9 Critical Reasons Why Precision Tooling is Essential for High-Quality PCB Manufacturing

The Strategic Importance of PCB Tooling in Global Electronics Manufacturing

In today’s competitive PCB manufacturing industry, precision tooling separates market leaders from low-cost providers. While some buyers focus solely on cheapest PCB quotes, experienced electronics manufacturers in China understand that advanced tooling systems directly impact product quality, yield rates, and total cost of ownership.

What Makes PCB Tooling Different From Standard Manufacturing Equipment?

PCB tooling refers to specialized equipment and processes that transform raw materials into functional printed circuit boards. Unlike generic machinery, these high-precision PCB manufacturing tools include:

- Laser-cut stencils for precise solder paste application

- Custom drilling jigs for multilayer board alignment

- Automated optical inspection (AOI) fixtures

- Test fixtures for functional verification

The PCB Tooling Process: How Top Manufacturers Ensure Quality

Leading PCB manufacturers in China follow a rigorous tooling preparation process:

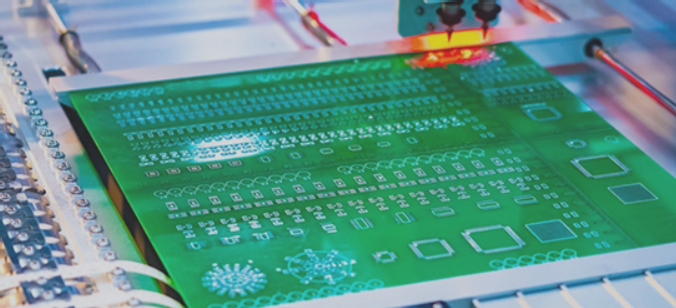

1. Stencil Fabrication for SMT Assembly

Using advanced CAD/CAM software, engineers create laser-cut stencils with micron-level precision. This ensures proper solder paste deposition for high-density PCB assemblies.

2. Drilling and Routing Tool Preparation

CNC-programmed tooling accounts for board thickness, copper weight, and material properties to prevent delamination and ensure precise hole drilling in PCBs.

3. Specialized Process Tooling

From press-fit connectors to RF shielding, custom tooling addresses unique PCB manufacturing challenges that generic equipment cannot solve.

9 Competitive Advantages of Proper PCB Tooling

“In high-volume PCB production, the right tooling reduces unit costs by 18-35% while improving first-pass yield rates above 98%.” – Global Electronics Manufacturing Report

1. Dramatic Cost Reduction in Mass Production

Proper PCB tooling solutions amortize across thousands of units, making them essential for high-volume PCB manufacturing. Our clients see 22-40% cost reductions after implementing optimized tooling strategies.

2. Accelerated Assembly Throughput

Custom fixtures and automated tooling enable fast PCB assembly while maintaining precision. Our production lines achieve 30% faster cycle times versus manual processes.

3. Material Waste Minimization

Advanced nesting algorithms in our PCB tooling software maximize panel utilization, reducing material costs by 15-25% compared to standard approaches.

4. Enhanced Electrical Performance

Precision-controlled impedance tooling ensures signal integrity in high-speed PCB designs, critical for 5G and IoT applications.

5. Improved Thermal Management

Specialized thermal relief tooling prevents overheating in power electronics PCBs, extending product lifespan.

6. Consistent Quality Across Batches

Our automated PCB inspection tooling maintains ±0.01mm tolerances throughout production runs of 100,000+ units.

7. Design Flexibility for Complex Boards

Advanced tooling enables reliable manufacturing of HDI PCBs with microvias and fine-pitch components.

8. Reduced Time-to-Market

Proper DFM tooling analysis prevents 83% of common PCB manufacturing issues before production begins.

9. Global Supply Chain Compatibility

Our tooling systems meet international PCB standards including IPC-6012, ISO 9001, and IATF 16949 for automotive applications.

Essential PCB Design Tools for Manufacturing Success

To leverage advanced tooling benefits, designers need professional-grade software:

- Altium Designer – Comprehensive tool for complex, high-layer count PCBs

- Cadence Allegro – Industry standard for high-speed digital designs

- Mentor Xpedition – Advanced tooling for aerospace and defense applications

- Zuken CR-8000 – Cutting-edge solution for automotive electronics

Partnering With the Right PCB Tooling Expert

When selecting a PCB manufacturing partner in China, verify their tooling capabilities:

- On-site tooling design and fabrication

- Automated optical inspection systems

- Continuous tooling maintenance programs

- Tooling lifecycle management

Our PCB tooling engineering team works closely with clients to develop customized solutions that balance performance requirements with manufacturing realities. Contact us today to discuss how optimized tooling can transform your PCB production.