Quick Turnaround PCB Prototyping

The quick-turnaround PCB prototyping process allows engineers to bring their ideas to life rapidly for iterative testing.

High-Quality PCB Prototyping

PCB prototyping services ensure precision, reliability, and durability to meet stringent specifications, guaranteeing high-quality final products.

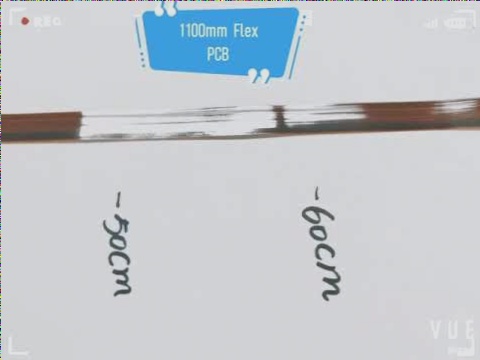

Versatile Options for PCB Prototyping

PCB prototyping companies offer services ranging from small-scale prototypes to full-scale production, accommodating various complexities and quantities to cater to diverse client needs.

Flexibility in PCB Prototyping

PCB prototyping services support modifications and additional functionalities during the prototype phase, facilitating continuous improvement and adaptability.

Cost-Effective PCB Prototyping

PCB prototyping services optimize manufacturing processes and scale economies to provide competitive pricing without compromising quality.

Timely Delivery of PCBs

PCB prototyping services prioritize punctual delivery, ensuring that PCBs reach clients within agreed-upon timeframes for seamless project progression.

Advancements in PCB Industry

The rapid growth in the PCB circuit board industry is fueled by a wide array of high-tech digital products, meeting the escalating demands for electronic precision.

Quality Criteria for Prototype PCBs

- Adherence to standardized size and thickness

- Attention to detail in light and color

- Importance of welding aesthetics

- User-friendly operation post-component installation

- Alignment of line dimensions with specifications

Industrial PCB Assembly

In industrial electronics, Printed Circuit Boards (PCBs) are crucial for ensuring optimal performance of equipment and machinery.

PCB assembly is a critical process that demands precision, expertise, and adherence to stringent quality standards.

Key Considerations for Industrial PCB Assembly

- Component Selection: Choosing components that withstand harsh conditions

- PCB Design: Importance of a well-thought-out design for performance optimization

Industrial PCB Considerations

- Industrial PCBs face challenges like complex circuitry, high-speed signals, and space constraints.

- Designers must focus on signal integrity, thermal management, and EMI/RFI shielding for optimal functionality.

Assembly Techniques

- The assembly process is crucial for PCB quality.

- Commonly used techniques include surface mount technology (SMT) and through-hole assembly.

Quality Control

- Rigorous quality control is essential to identify and rectify defects.

- Techniques like automated optical inspection (AOI) and X-ray inspection ensure integrity and reliability.

Compliance and Certification

- Industrial PCBs must meet industry standards.

- Certifications like IPC-A-610 show adherence to quality standards, building user confidence.

Environmental Protection

- PCBs in industrial settings face contaminants, moisture, and extreme temperatures.

- Conformal coating and encapsulation protect PCBs, enhancing longevity and reliability.

Supply Chain Management

- A robust supply chain is crucial for uninterrupted production.

- Collaboration with reliable suppliers and efficient inventory management streamline the assembly process.

Conclusion

Industrial PCB assembly is complex but vital in modern manufacturing. By focusing on component selection, design, assembly techniques, quality control, compliance, environmental protection, and supply chain management, manufacturers can meet the demanding requirements of industrial applications.